| Monthly Tech-Tip | No tracking! No ads! |

Medium fire white bodies used at cone 04. Is that smart?

Low-temperature white talc casting bodies have always been porous, 10-12% absorption is typical - pieces are basically just bisque-fired. People just pretend everything is fine! A stoneware potter might be horrified by this - until he/she sees the bright colors and brilliant glazes! If a dolomite body alternative is not available to you or your supplier is making a talc body that is no longer white there is an alternative: Use a middle-temperature white burning body. Why is this even possible? Their porosity at cone 05 is also 10-12% - but won't commercial glazes craze? Yes. So just make your own. This is G1916QL1 applied thickly on Polar Ice, P300, M370 (and L213 talc body), these are all plastic bodies but they can be adjusted for casting (removal of the bentonite). None crazed out of the kiln or after a BWIW test. I did this again with a thinner glaze application and at cone 03 (100°F hotter) and the results were even better. G1916QL1 can be mixed as a dipping or brushing glaze. But how can you guarantee no crazing? Fire even hotter, perhaps cone 02. Lower the thermal expansion further (as per instructions on its web page). And increase the silica in the body recipe at the expense of kaolin or ball clay (compensate with whatever bentonite is needed to get good casting properties). For a good cone 6 porcelain recipe for casting try L3778G. All of this can also be done with a plastic body, for that try L3778D.

Related Pictures

Two low fire transparent highly fritted glaze recipes for pottery

This picture has its own page with more detail, click here to see it.

These work well from cone 04 up, they are better than any commercial transparent brushing glaze we have used. And far better than glazes made using raw sources of boron (like ulexite, colemanite, Gerstley Borate). These glazes have lower thermal expansion and do not craze on any body we have tried (yet are ultra gloss and ultra-clear). They are G1916QL1 and G3879C. We developed them for use on the dolomite-based (rather than talc-based) L4410L low-temperature art clay body. These are a good demonstration of the technical and economic sense it makes to use highly fritted glazes at low temperatures. Having a good base glaze is the key to adopting low temperatures for your production. You would likely agree that no stoneware glaze has melting patterns like these shown in this melt fluidity test! These recipes and all details about their development and adjustment are openly available.

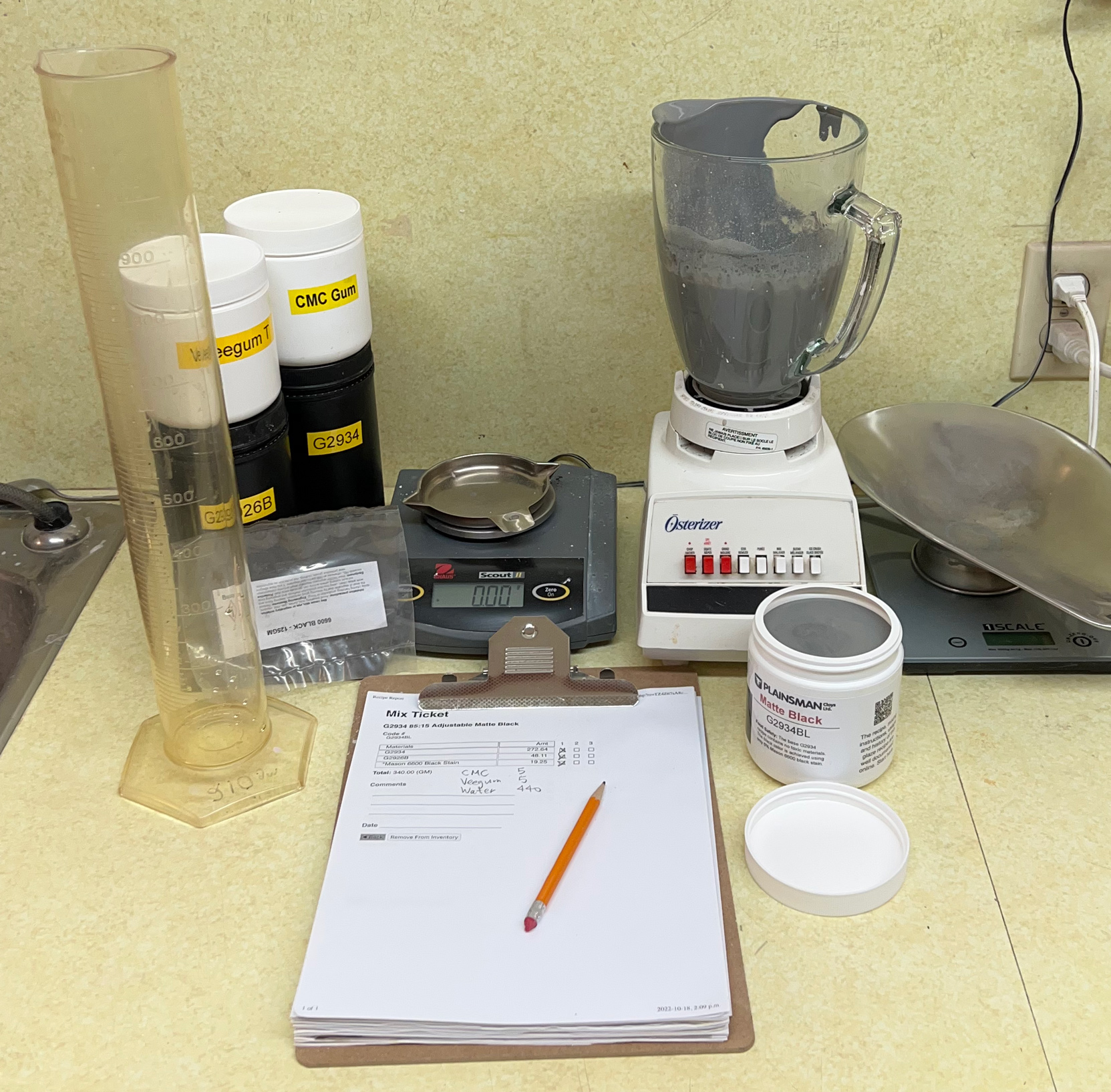

Here is my setup to make brushing glazes and underglazes by-the-jar

This picture has its own page with more detail, click here to see it.

Although I promote DIY dipping glazes, you can also make DIY brushing glazes. Let's make a low SG version of G2934BL. Weigh out a 340g batch of dipping glaze powder. Include 5g Veegum (to gel the slurry to enable more than normal water) and 5g CMC gum (to slow drying and impart brushing properties). Measure 440g of water initially (adjusting later if needed). Shake-mix all the powder in a plastic bag. Pour it into the water, which is blender mixing on low speed, and finish with 20 seconds on high speed. This just fills a 500ml jar. In subsequent batches, I adjust the Veegum for more or less gel, the CMC for slower or faster drying and the water amount for thicker or thinner painted layers. Later I also assess whether the CMC gum is being degraded by microbial attack - often evident if the slurry thins and loses its gel. Dipping glaze recipes can and do respond differently to the gums. Those having little clay content work well (e.g. reactive and crystalline glazes). If bentonite is present it is often best to leave it out. Recipes having high percentages of ball clay or kaolin might work best with less Veegum. Keeping good notes (with pictures) is essential to reach the objective here: Good brushing properties. We always use code-numbering (in our group account at Insight-live.com) and write those on the jars and test pieces. This is so worthwhile doing that I make quality custom labels for each jar!

High thermal expansion talc body cannot be COE-calculated

This picture has its own page with more detail, click here to see it.

Talc is employed in low-fire bodies to raise their thermal expansion (to put the squeeze on glazes to prevent crazing). These dilatometer curves make it very clear just how effective that strategy is! The talc body was fired at cone 04 and the stoneware at cone 6. The former is porous and completely non-vitreous and the latter is semi-vitreous. This demonstrates something else interesting: The impracticality of calculating the thermal expansion of clay bodies based on their oxide chemistry. Talc sources MgO and low fire bodies containing it would calculate to a low thermal expansion. But the opposite happens. Why? Because these bodies are composed of mineral particles loosely sintered together. A few melt somewhat, some change their mineral form, many remain unchanged. The body's COE is the additive sum of the proportionate populations of all the particles. Good luck calculating that!

Videos

Links

| Glossary |

Artware

Artware, to potters and hobbyists, is pottery made from white-burning clays fired at low temperatures with brightly coloured glazes and decorated using decals, underglazes, lustres, etc. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy