| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Gradient test bars show how a range of temperatures affects a clay

These are the fronts and backs of dust-pressed and fired gradient bars. They were done by Luke Lindoe in the I-XL brick lab to assess the firing history on two clay samples from Montana. After final drying, the bar width at each line is carefully recorded. They are fired horizontally in a furnace capable of reproducing linear thermal gradients along the length of the bar (equally spaced thermocouples enable control in each micro-zone). After firing, the widths are re-measured. The data produces a graph of fired shrinkage vs. temperature. Bars can also be visually inspected side-by-side for differences (color being the most obvious but also surface character). This method of comparatively assessing the effect of temperature on a clay test bar is popular in the brick industry (e.g. when a new mining of clay is being compared with a previous one). However, the SHAB test, although requiring more effort, provides more information and is more accurate (e.g. for pottery and porcelain).

Related Pictures

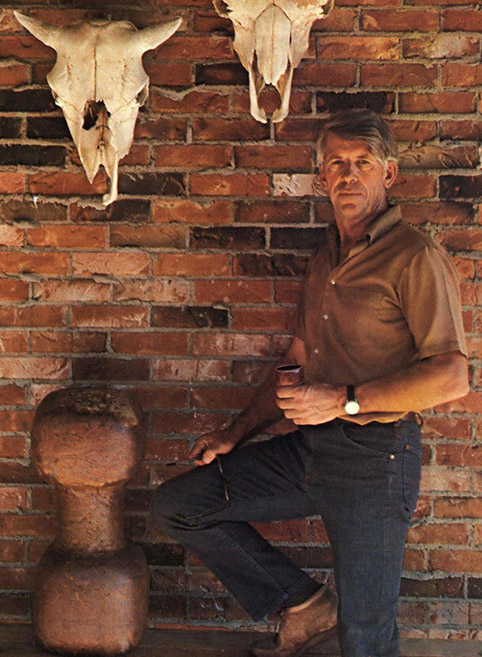

Luke Lindoe in 1971

This picture has its own page with more detail, click here to see it.

He was the founder of Plainsman Clays. My dad had just built the Plainsman Clays factory for him and I began working there in 1972 (this picture was taken at his house, which my father also built). He was a well-known artist potter and sculptor at the time, having come out of the pottery production industry in the area. He got me started along the fascinating road of understanding the physics of clays. He was a true "plains man", interested in the geology of the plains (notice the skulls, these inspired the Plainsman logo). He got me started doing physical testing of raw clays (that he was finding everywhere). I was blown away by the fact that I could assess a completely new material and judge its suitability for many types of ceramic products and processes by doing the simple physical tests he showed me. It got started writing software to log the data for that back in the 1980s, that eventually led to digitalfire.com and Insight-live.com.

Videos

Links

| URLs |

https://www.ortonceramic.com/en/Gradient%20Furnaces/

Orton Gradient Furnaces |

| URLs |

https://www.ortonceramic.com/_files/ugd/48fea3_2dbe9166e60449f4b84ac762ce48c3d5.pdf

Orton Thermal Gradient Furnace PDF brochure The furnace fires one bar or a series of samples at different KNOWN temperatures in one heating chamber in one firing. Each sample is measured to study the effects of temperature on the ceramic properties of interest. |

| Glossary |

Firing Shrinkage

During drying, clay particles draw together and shrinkage occurs. During firing the matrix densifies and shrinkage continues. More vitreous bodies shrink more. |

| Glossary |

Maturity

A term used in the ceramics industry to signify the degree of vitrification in a fired clay. Mature clays are dense and strong, immature ones porous and weak. |

| Glossary |

Brick Making

Brick-making is surprisingly demanding. Materials blending and processing, forming, drying and firing heavy and thick objects as fast as possible are like no other ceramic manufacturing challenge. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy