| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

The Floating blues we should have manufactured

The closest we got was labels

This is not sold in jars, I make my own labels to demonstrate that DIY brushing glazes are not only possible, but can be better. The G2917 glaze is less melt-runny than typical floating blues. It contains the standard rutile/iron addition but adds a little cobalt to ensure a good blue color no matter how the kiln cools. The L4655 Alberta Slip floating blue (left), contains no rutile, iron or even cobalt - it employs titanium dioxide (using iron available in the body and slow cooling as the mechanism of the blue). Both have a big advantage over the original G2826R recipe from 50 years ago: they don't contain any Gerstley Borate, so the slurries don't turn to jelly in the bucket, both mix naturally as thixotropic dipping glazes.

Related Pictures

Titanium instead of rutile for floating blue

This picture has its own page with more detail, click here to see it.

Rutile blue glazes are actually titanium blues (because rutile mineral is an impure source of TiO2 and Fe2O3). The iron and titanium in the rutile react to form the floating blue effect. The GA6-C recipe has always relied on a 4% rutile addition. Its GA6-A base recipe contains significant iron (because of the 80% Alberta Slip), so could titanium oxide deliver the same floating blue effect? Yes.

These mugs are M390 clay. The top left one is the standard GA6-C (with rutile) fired using the C6DHSC slow-cool firing schedule (the bottom left normal cool PLC6DS schedule produces little color). But the ones on the right switch the 4% rutile for titanium dioxide (the L4655 recipe). The top right was fired using the slow cool, the bottom right was the normal cool schedule.

Titanium thus seems more consistent and reliable material than rutile. An excellent blue color is produced even without a slow cool (lower right).

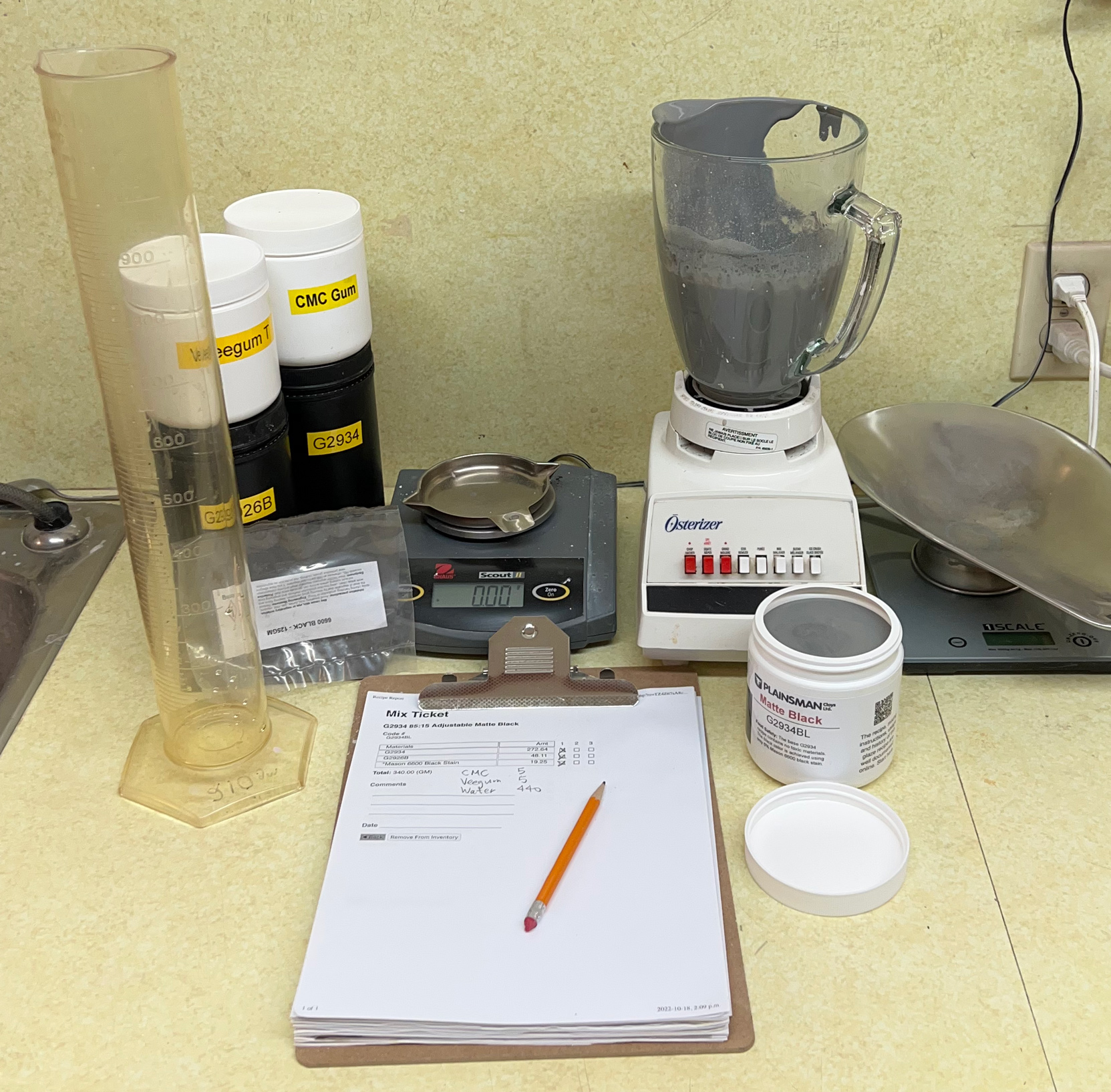

Here is my setup to make brushing glazes and underglazes by-the-jar

This picture has its own page with more detail, click here to see it.

Although I promote DIY dipping glazes, you can also make DIY brushing glazes. Let's make a low SG version of G2934BL. Weigh out a 340g batch of dipping glaze powder. Include 5g Veegum (to gel the slurry to enable more than normal water) and 5g CMC gum (to slow drying and impart brushing properties). Measure 440g of water initially (adjusting later if needed). Shake-mix all the powder in a plastic bag. Pour it into the water, which is blender mixing on low speed, and finish with 20 seconds on high speed. This just fills a 500ml jar. In subsequent batches, I adjust the Veegum for more or less gel, the CMC for slower or faster drying and the water amount for thicker or thinner painted layers. Later I also assess whether the CMC gum is being degraded by microbial attack - often evident if the slurry thins and loses its gel. Dipping glaze recipes can and do respond differently to the gums. Those having little clay content work well (e.g. reactive and crystalline glazes). If bentonite is present it is often best to leave it out. Recipes having high percentages of ball clay or kaolin might work best with less Veegum. Keeping good notes (with pictures) is essential to reach the objective here: Good brushing properties. We always use code-numbering (in our group account at Insight-live.com) and write those on the jars and test pieces. This is so worthwhile doing that I make quality custom labels for each jar!

Make and sell your own jars of glaze at your teaching studio

This picture has its own page with more detail, click here to see it.

Your studio or workshop can save a lot of money making and even selling your own glazes to students (at least for common colors and types). The supplies shown here enable printing quality labels on ordinary paper and applying them to jars that cost less than $2. We make the labels by ink-jetting onto regular paper, cutting them 62mm wide (2 7/16") and holding them securely in place using 2 7/8" transparent packing tape.

What about the glazes themselves? Just do what glaze companies do: Add stains to a base transparent glossy or matte glaze (for example G1916Q for cone 04 or G2926B for cone 6). Each 16oz jar needs 350g powder, 450g water, 5g CMC gum and 5g Veegum (leave out the Veegum and use less water for thicker coats). Stains are expensive (5-20 cents/gm here in 2024), at 7.5% (25g) that is $1-5 per jar. The materials for the G1916Q base cost $10/kg, and for G2926B $4/kg. Thus each jar costs $3.33 and $1.33 respectively. Making recipes of 5000g at a time would enable making 15 jars. A best-case is thus about $5/jar, worst case about $10/jar (compare that with commercials that are about $15-70). Of course, you can save money by looking for deals on materials and stains and recycling jars. Consider other advantages of making your own: You can tune the rheology and adjust recipes to fit your clay bodies (to prevent crazing or shivering).

Are you worried about labelled, testing and SDSs? Take a look at ASTM D-4236 and see if you still need to worry.

Videos

Links

| Typecodes |

Floating Blue

A popular cone 6 glaze that employed Gerstley Borate, it was very troublesome to use and to fire. Much work has been done to create alternative recipes. |

| Glossary |

Brushing Glaze

Hobbyists and increasing numbers of potters use commercial paint-on glazes. It's convenient, there are lots of visual effects. There are also issues compared to dipping glazes. You can also make your own. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy