| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

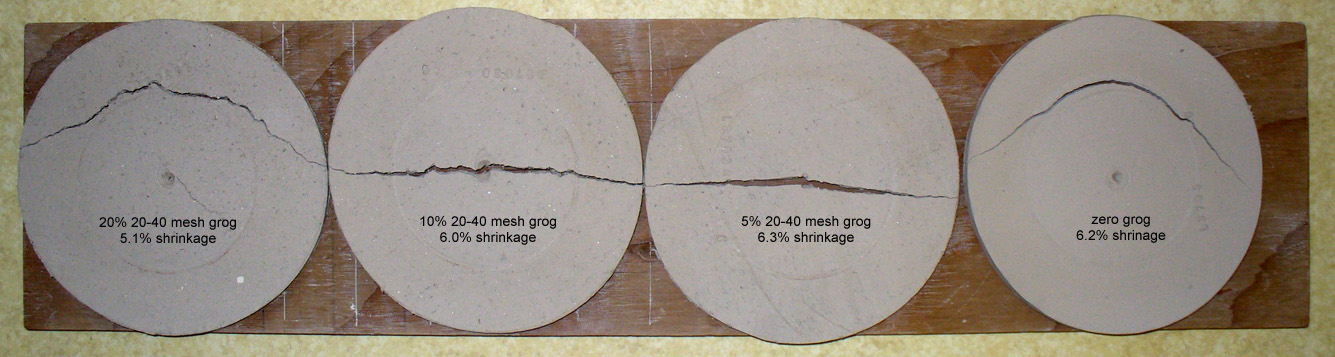

Grog does not always have the intended effect

These DFAC test disks (drying performance) show that minor additions of grog do not reduce the fired shrinkage of this medium fire stoneware much. Nor do they improve its drying performance. Even at 20% grog, although the addition has reduced drying shrinkage and narrowed the crack somewhat, it is still there and even resembles the zero-grog version. A possible reason is that this body is coarse-particled, having a relatively small total particle surface area. The addition of the grog has significantly increased the total area.

Videos

Links

| Materials |

Grog

|

| Tests |

Drying Factor

The DFAC Drying Factor test visually displays a plastic clay's response to very uneven drying. It is beneficial to show the relative drying performance of different clays. |

| Glossary |

Drying Performance

In ceramics, drying performance is very important to optimizing production. More plastic clays shrink more and crack more, but they are also better to work with. |

| Glossary |

Drying Shrinkage

Clays used in ceramics shrink when they dry because of particle packing that occurs as inter-particle water evaporates. Excessive or uneven shrinkage causes cracks. |

| Glossary |

Grog

Grog is a term used in ceramics to describe crushed brick (or other fired ceramic) aggregate that is added to sculpture and structural clays to improve drying properties. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy