| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Adding 6% lithium carbonate to an Alberta Slip glaze does this

Left is G3933A, it is an 80:20 mix of our matte and glossy cone 6 base recipes (plus a mix of iron oxide, tin oxide and rutile). The body is Plainsman Coffee Clay. Because of repeated issues with crawling a project was started to create the same effect using Alberta Slip to supply as much of the chemistry as possible. Along that road, the opportunity arose to add lithium (to duplicate Amaco PC-32, a classic Albany/Lithium recipe). That is the glaze on the mug on the right, G3933G1, it has 6% lithium carbonate. Lithium is a super powerful melter, turning this into a very reactive glaze! To make a 500ml jar of brushing glaze, in 2023, required about $7 worth of lithium carbonate.

Related Pictures

Oatmeal glazed mugs

This picture has its own page with more detail, click here to see it.

These glazes are made from Ravenscrag Slip, this color is often referenced "Oatmeal". I add iron oxide to get the effect on the left. Then I add lithium carbonate to get the one on the right, that is the G3933G1 recipe.

Amaco achieves the stunning look of PC-32 Albany Brown glaze using lithium

This picture has its own page with more detail, click here to see it.

Left is G3933A, an Alberta Slip based glaze. Right is Amaco PC-32, Albany Slip Brown. They are likely using a similar base recipe, but the difference is added lithium carbonate to supercharge the melting. That converts it to a type of reactive glaze (one that changes its appearance with differing thicknesses). Where thick in the recesses it crystallizes to a much lighter color. On contours, it runs thinner amplifying the brown body color. The use of lithium explains why PC-32 is more expensive. Lithium prices are rising so fast it may not continue to be practical for manufacturers to continue making some lithium glazes (hopefully this one is safe since the percentage is relatively low).

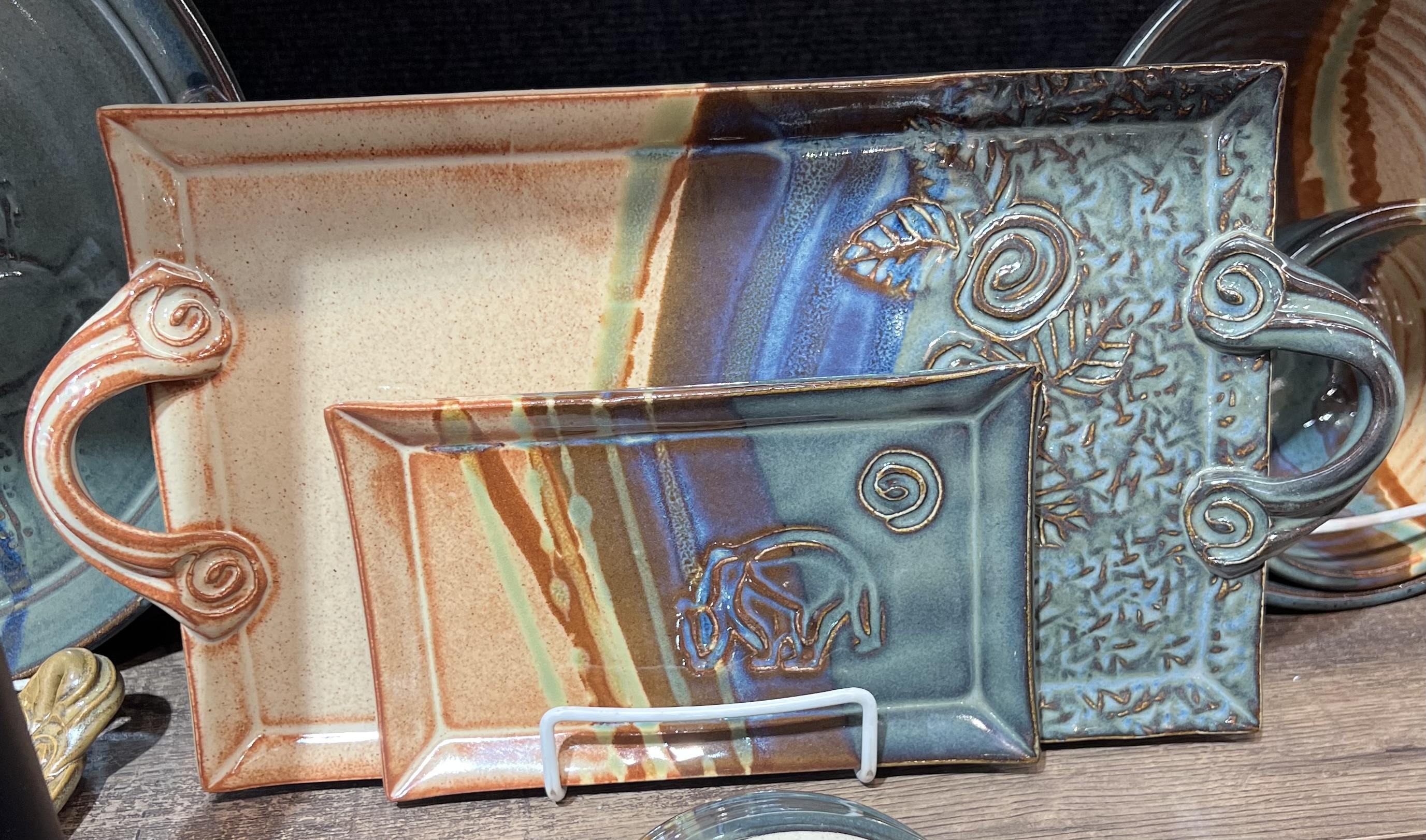

Recognize these universal oxidation glazes?

Almost every potter needs a Albany brown and rutile blue.

This picture has its own page with more detail, click here to see it.

These are made by Barbara Childs Pottery (I saw them on sale in a tourist shop in Alaska). To keep costs down, I first assumed they use dipping glazes they mix themselves. Potter's Choice PC-32 Albany Slip Brown and PC-20 Rutile Blue hobby glazes emulate these long time pottery glaze recipes. However, a reader noted that Barabara Childs uses Clay Art Center’s Stellar Rust and Floating Blue (with guest appearances by Blue Green). But Amaco and Clay Art don't just use the traditional recipes; they adapt and improve them. Consider the rutile blue. Neither is using the traditional G2826R floating blue recipe, there are new and better ways using recipes like GA6-C and GR6-M. Likewise, with the brown, they are not using the traditional G2415E Albany Brown recipe. Rather, they improve it (e.g. like we did with G3933G1). High on their list of improvements would have been a way to reduce or remove the lithium to cut costs. Maybe you are a hobbyist and don’t feel you need to DIY your costs down. But do your customers feel the same way? Not buying just ten small jars of hobby brushing glaze will pay for a mixer and much of the ingredients to make gallons of each of these as dipping glazes. It will also set you on the road to gradually improving the glazes you use. And even reducing your prices. What about buying premixed powders? Yes, that is much less expensive. But if you are mixing the glaze from one manufacturer with the clay body from another, crazing is an ever-present issue. Mixing your own enables an adjustment to fix the problem.

Videos

Links

| Recipes |

GA6-G - Alberta Slip Lithium Brown Cone 6

Plainsman Cone 6 Alberta Slip based glaze. |

| Materials |

Lithium Carbonate

A powerful melter very valuable in ceramic glazes. It is 40% Li2O and has an LOI of 60% (lost as CO2 on firing). This material in now incredibly expensive. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy