| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Another compelling reason for DIY casting bodies and glazes

These are four different cone 6 commercial glazes made by a popular US manufacturer. The body is a cone 6 casting porcelain made by another popular manufacturer. They are all crazing! This is visible because the glaze is transparent, but most often it is much more difficult to see. Guess what many people are doing? Ignoring the problem and selling the ware! Assuming you are not one of them - which company is at fault? Neither. They cannot assure their product fits those of others. Mid-fire porcelains craze glazes if they lack sufficient silica (20% is minimum) or don't vitrify. Unfortunately, the recipe of the porcelain is proprietary. Wait a minute - no, it isn't. These recipes are well-known. You already have a propeller mixer and scale to mix casting slip, why not mix your own porcelain from a recipe (e.g. L3778D or derivative)? Or, why not mix your own transparent brushing glaze or dipping glaze? Start with the G2926B recipe, it has lots of documentation, and the recipe can be adjusted to deal with fit issues on any clay body.

Related Pictures

Glazes Are Crazing on This Casting Porcelain

The casting process enables a unique and effective fix

Generated with a prompt for a crazed glaze on a slip cast mug

Generated with a prompt for a crazed glaze on a slip cast mugThis picture has its own page with more detail, click here to see it.

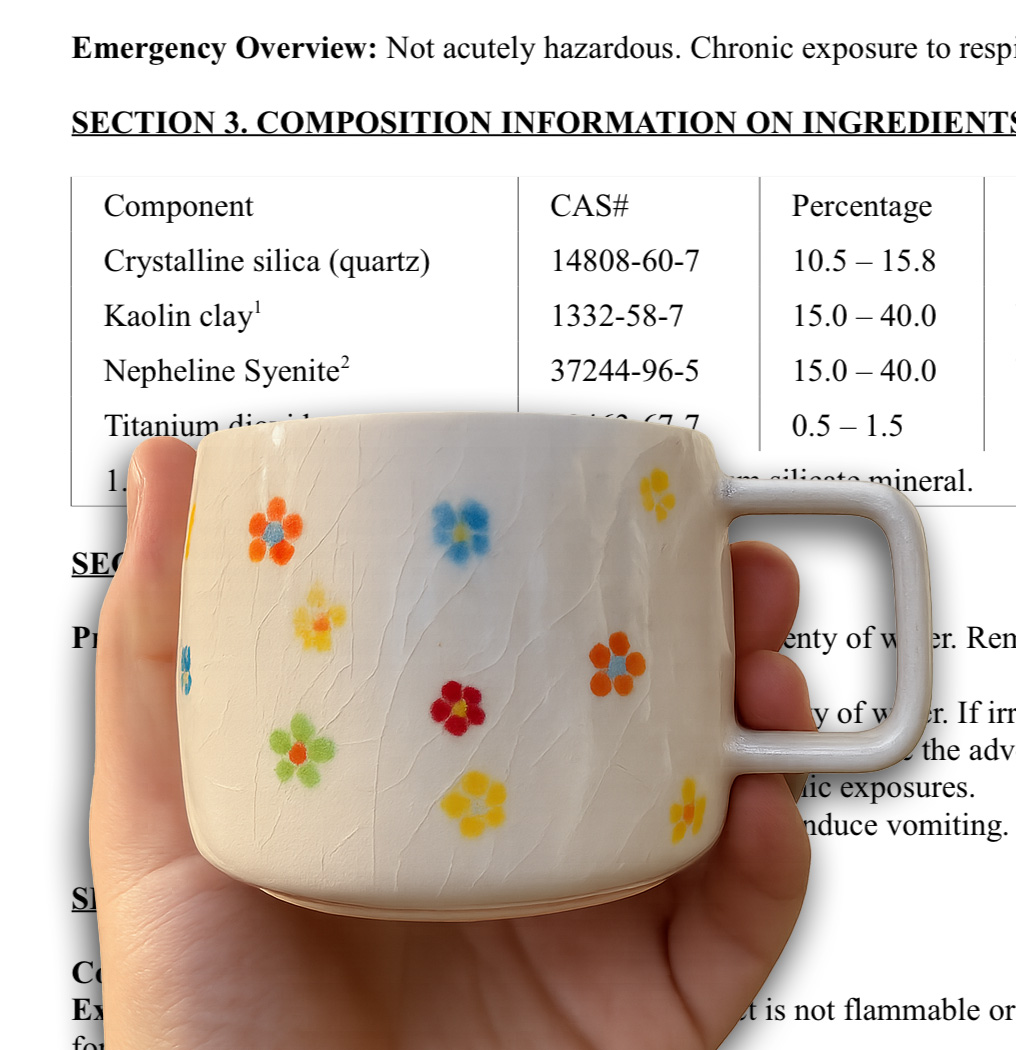

This potter almost has the casting process working, making these beautiful porcelain mugs. They are fired at cone 6 using a transparent glaze over underglaze decoration. But the devil is in the details. Look closer to see it: Crazing. Why? The reason is evident on the SDS for the body. Notice it has 10.5-15.8% crystalline quartz (or silica). This is not enough to prevent crazing in typical glazes.

Almost always, the solution is to find or formulate a clear glaze having a lower thermal expansion (in this case, a lot lower). But with casting bodies, we have another option: Mix our own. Unlike glazes, porcelain recipes are typically just three materials: kaolin, feldspar and silica. The starting percentages are simple for cone 6: 30% feldspar to vitrify. And 25% silica to fit the glaze. That leaves 45% kaolin. It is that easy! Start with the L3778G recipe. Its information page is also a launching pad for dozens of links, enabling you to dig as deep as desired into understanding casting slips (the materials are cheap, so losing a few batches while you learn deflocculation is not a problem). Still think it is too difficult to mix our own? Consider that you need a propeller mixer anyway to prepare and adjust the slip and reprocess scrap. By mixing your own you'll be a more effective, and flexible slip caster.

Videos

|

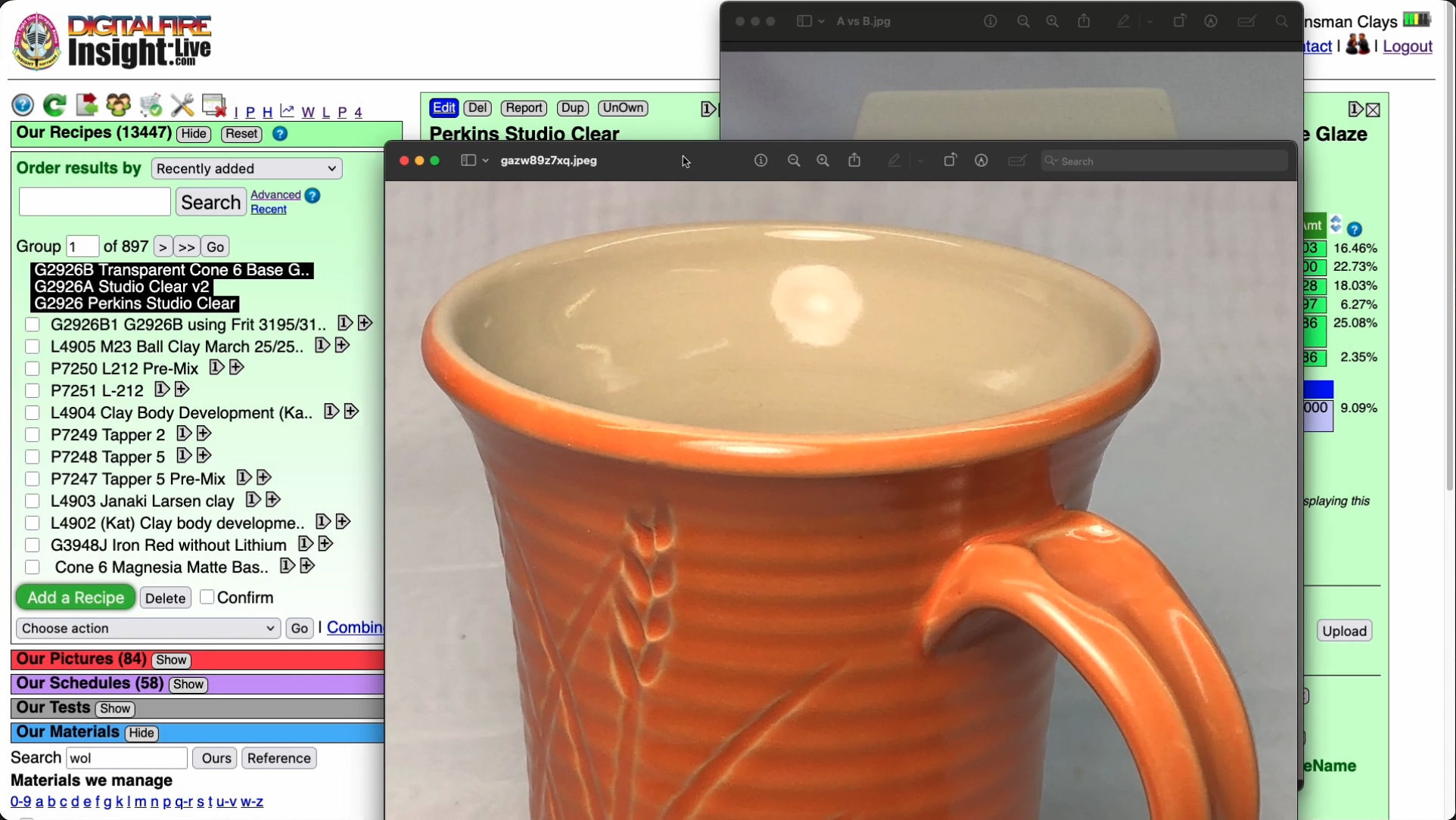

How I Developed the G2926B Cone 6 Transparent Base Glaze

How I found a pottery glaze recipe on Facebook, substituted a frit for the Gerstley Borate (using glaze chemistry), compared using a melt flow tester, added as much extra SiO2 as it would tolerate, and got a durable and easy-to-use cone 6 clear. |

Links

| Glossary |

Deflocculation

Deflocculation is the magic behind the ceramic casting process, it enables slurries having impossibly low water contents and ware having amazingly low drying shrinkage |

| Glossary |

Fluid Melt Glazes

Fluid melt glazes and over-melting, over fired, to the point that they run down off ware. This feature enables the development of super-floss and cyrstallization. |

| Articles |

Where do I start in understanding glazes?

Break your addiction to online recipes that don't work or bottled expensive glazes that you could DIY. Learn why glazes fire as they do. Why each material is used. How to create perfect dipping and brushing properties. Even some chemistry. |

| Articles |

Glaze Recipes: Formulate and Make Your Own Instead

The only way you will ever get the glaze you really need is to formulate your own. The longer you stay on the glaze recipe treadmill the more time you waste. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy