| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

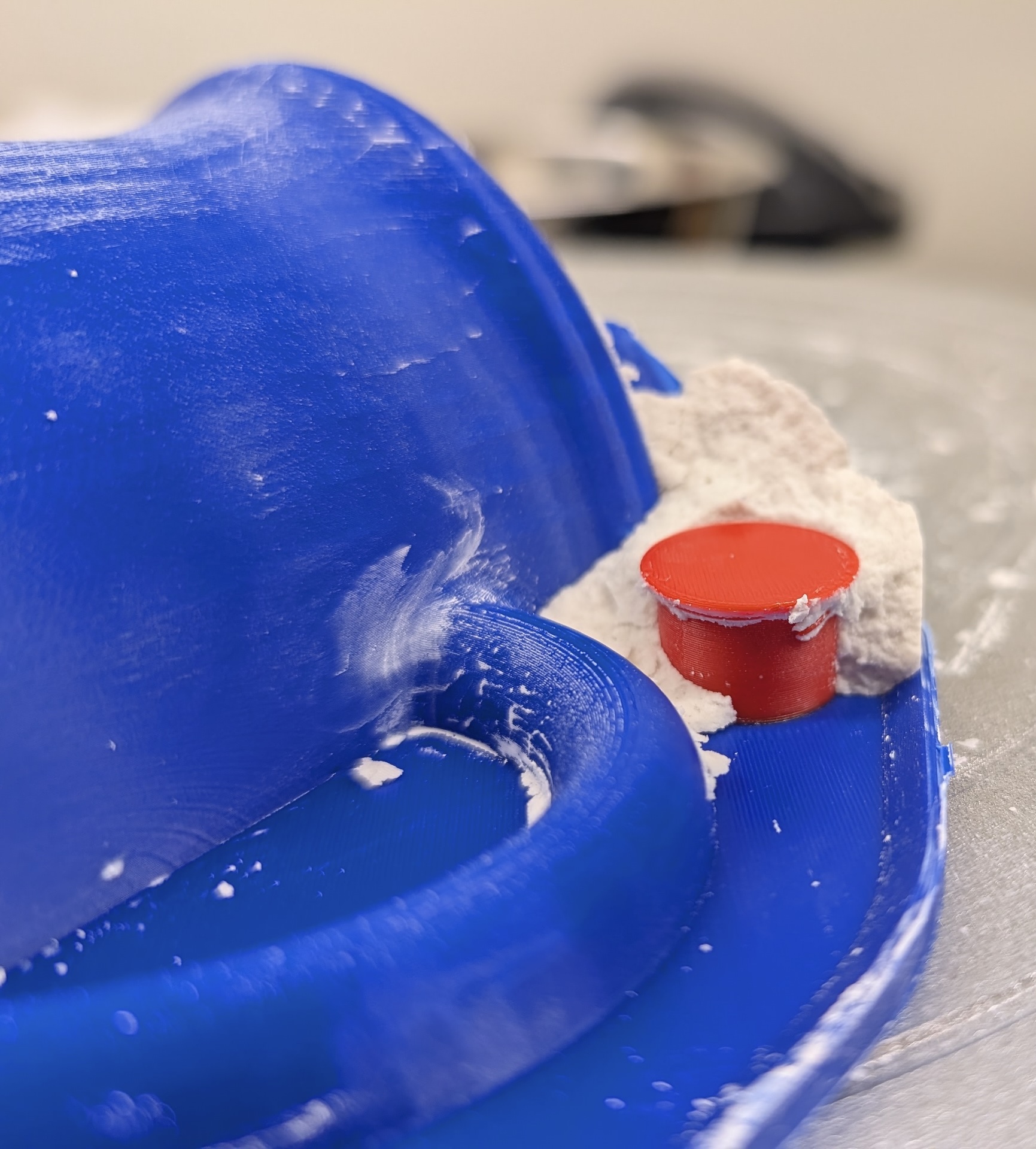

Here’s What Happens Without a Heat Gun

The plaster broke around the embed when trying to extract it from this 3D printed mold. The problem? It is impossible. Here is why: Most of our recommendations are for prototyping and the production of limited numbers of molds (what a potter would need). This enables printing at 0.8 wall thickness to shorten print times and minimize filament use. And it involves no fix up of printing artifacts. This mandates removal of the 3D print from the plaster using a heat gun. The PLA mold is sacrificed, it becomes an unrecognizable twisted mass of plastic after removal. We remove the plastic shell after the plaster has set and cooled down. But plan it, consider the edges most likely to chip or break away and soften the plastic more on those sections (almost melting if needed). We use a large needle nosed pliers to grasp the deforming plastic in the needed place and carefully pull it as it softens. Avoid getting too much hot air into the natch embeds.

Some brands of PLA emit fumes during this process, others do not. Do it in a well mentioned area if needed. Wear gloves, heat guns can seriously burn you (don’t bother with a hair drier, it’s not hot enough, heat guns are inexpensive).

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy