| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Silica

Description: Quartz, Flint

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| SiO2 | 100.00% | 1.00 | |

| Oxide Weight | 60.10 | ||

| Formula Weight | 60.10 | ||

Notes

The term 'silica' can be misleading. It is important to understand the difference between 'silica mineral', 'silicates', and 'silica glass'. Quartz is the best example of a natural mineral that is almost pure silicon dioxide (it is the most abundant mineral on planet earth). Other ceramic minerals like feldspar and clay contain some 'free silica' (accessory quartz). However these also usually contain 'silicates', that is, SiO2 chemically combined with other oxides to form crystalline minerals. Other silica-containing rocks and minerals are andalusite, barite, beach sand, bentonite, calcite, diatomaceous earth, kaolin, limestone, mica, pyrophyllite, talc, tripoli, rutile, wollastonite, zeolite, zirconium sand, vermiculite, granite, and sandstone. Silica is also available as a silicate glass (in frits).

Pure silica minerals (like quartz) have high melting points. In ceramic bodies and glazes other oxides are added to complement it, they form silicates with it or occupy the network between particles of quartz. In the latter case silica is considered a 'filler' (e.g. porcelain clay bodies). Interestingly, some special purpose (and expensive) clay bodies replace the silica filler with calcined alumina, this increases body strength and reduces thermal expansion.

Individual particles of quartz have a high thermal expansion (and associated contraction) and significantly change their volume as they pass up and down through 'inversion' temperature points during firing. This can cause a form of body cracking called 'dunting' (because only some of the silica gets dissolved in the feldspar glass melt). The cracking occurs as micro-cracks radiate out from each microscopic particle of quartz and propagate into larger cracks. High quartz bodies are usually unsuitable for ovenware and ware that must tolerate sudden temperature changes. However, this behaviour is advantageous to glaze fit since it puts the 'squeeze' on the glaze to prevent crazing. At the same time, silica in glazes tends to dissolve and form low-expansion silicates that reduce glaze expansion and also prevent crazing. In both cases, silica powder of small grain size is advantageous. Sanitaryware producers use finer grades of silica (and lower percentages) in the body to minimize issues with quartz inversion.

While it is convenient to think that quartz particles dissolve in the glaze melt to combine with other oxides to produce silicates reality can be quite different. As noted, quartz particles do not melt at any common ceramic temperatures, they must be dissolved into the melt by other things that have already melted. The completeness of this depends on particle size, time, temperature and fluidity and nature of the melt. Potters, who fire slowly and at high temperatures, are least affected by this issue (those firing low and fast most affected). Thus, in industry, where fast-firing is the norm, silica-containing glazes must be ball-milled. Sourcing SiO2 to the glass from frits or raw materials that release it more easily (like feldspar, wollastonite, pyrophyllite) is also help. Thus, a typical high-temperature stoneware glaze for potters might have 30% silica whereas a fast-fire industrial glaze might have none. If you are a potter and one of your glazes has 30% silica, you really should be ball milling it or using 325 mesh silica. For low temperatures, these principles are even more important.

High-temperature traditional ceramic bodies tend to have up to 30% silica whereas low-fire ones have much less or none (because of its refractory nature). However, in recent years many companies substitute kyanite, pyrophyllite or similar minerals for part of the quartz to minimize thermal expansion (see article in Studio Potter vol 28 #1 by Peter Sohngen). Very fine grades of silica aid in cristobalite formation in stoneware bodies (cristobalite is a form of silica that goes through it's inversion at about 200C).

When limestone and silica are available in a body they can react to form wollastonite. This adds mechanical strength and is exploited in tile bodies. For optimal results, the relative percentages must be in balance and the forming and firing methods tuned to optimize the effect.

High-temperature glazes can have 40% or more silica (if enough flux is available to react and form silicates).

Microfine silica grades have particle sizes less than 1 micron, this is far finer than any ceramic grade of silica (45 microns are larger). These fine grades are, for example, used in the refractories industry to fill voids in between other particles to increase density and lower the amount of water needed.

Related Information

A load of 800 bags of silica arriving at Plainsman Clays

This picture has its own page with more detail, click here to see it.

Each of these bags is batch-numbered and time-stamped; this is an impressive product-tracking effort by US Silica. It appears the time changes once per minute; their plant thus appears to produce about 600 bags/hour. They stack 60 bags on a pallet, 3000 lbs! The only material I have seen that is stacked more densely is plaster, 80 bags per pallet at 4000 lbs. Pugged clay, by contrast, is stacked at 40 boxes/pallet, giving 1760 lbs.

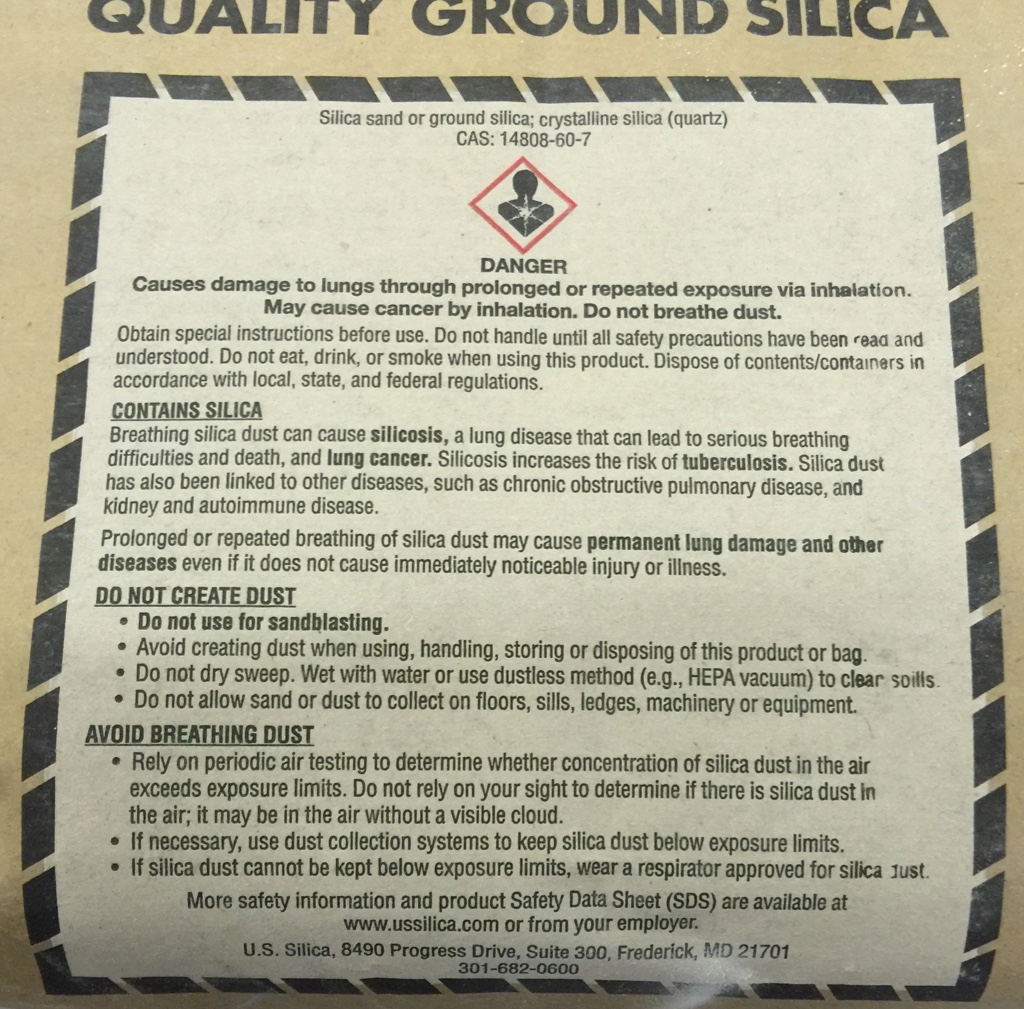

Health warning phrases on a bag of ground silica

This picture has its own page with more detail, click here to see it.

The difference between Silica 90 and Silica 45 will affect the glaze melt

This picture has its own page with more detail, click here to see it.

Quartz particles have a high melting point, they must enter the glaze melt by being dissolved by it (usually the last particles to do so). Obviously, the silica should be as fine as possible to increase its surface area to be more readily dissolved. The more that dissolves the closer the physical properties of the fired glaze will be to the theoretical (e.g. degree of melting, thermal expansion, transparency, durability). This brand of silica, #90 classifies as 200 mesh even though 2.8% remains on the 200 mesh screen. Not surprisingly, their #45 grade retains 1.9% on the 325 mesh screen. However, the most significant aspect is how much of the #90 is on the 325 and 270 mesh screens: 26%. The #45 grade only retains 2.6% on them! This is a huge difference and shows the value of using the finer material. It would take a typical ball mill hours to make this difference.

45 micron silica is amazing in low temperature pottery glazes

This picture has its own page with more detail, click here to see it.

This is G1916Q3 low-temperature transparent glaze (it is the G1916Q recipe plus 10% 45-micron silica). Silica is a highly refractory material, this low-temperature glaze should not have been able to dissolve that much of an addition without cost to the gloss, melt fluidity or transparency. But none of these has happened and the reason is, in good part, because of the finer particle size of the silica powder: 45 microns (or 325 mesh). It is applied fairly thick and is runny enough to have pooled at the base. And it is still ultra glossy. A big benefit of the silica being present and having dissolved so well in the melt well is an almost certain increase in the durability and hardness of the glaze. Another benefit is a reduction in the thermal expansion, that is proven by the glaze shivering off the rim (on the far right). This body is Plainsman L215. So, while not suitable on this body, this glaze is ready to be used on others that craze the parent G1916Q recipe. And it has a thermal expansion adjustable recipe, a base frit and about 15% each of a low and high expansion frit. That means some high-expansion Ferro frit 3110 can be introduced at the expense of low expansion Ferro frit 3249.

This amazing difference 45 micron silica can make

This picture has its own page with more detail, click here to see it.

The only difference between these two cone 6 glazes is the silica. Both are the G2926B recipe, both were thickly applied and fired in the same kiln. The left one employs the 90 micron (or 200 mesh) grade silica and the right one uses 45 micron (or 325 mesh). These test tiles are about 6 months old. There was no crazing out of the kiln. The porcelain recipe is 25% silica, 25% nepheline and the remainder kaolin and bentonite. It appears the finer particle size silica is dissolving in the melt much better, this narrows the difference between calculated and actual behavior, especially relating to coefficient of thermal expansion. While this grade is better in glazes it is not better in bodies, they most often depend on the thermal expansion increasing effects of the larger particles in the 200 mesh grade.

A reader noted that it is also a matter of the reaction between glaze and body. The original glaze having coarser silica would have smelt and reacted with the body more, the extra dissolution sourcing Na2O - thus increasing the COE of the glaze. Conversely, when the finer silica dissolves it increases melt viscosity thus reducing reaction with the body.

A pure silica suspension that behaves like a glaze. Is that possible? Yes.

This picture has its own page with more detail, click here to see it.

This slurry is just water and 295 mesh silica. I have mixed it to 1.79 specific gravity and it is creamy. It applies like a glaze to bisque ware (if I dip it fast) and goes on super smooth and even. It does settle, but only slowly. Unlike feldspar and nepheline syenite, if I thin it a little and add powdered epsom salts or vinegar it does not gel, no matter how much I put in. The only response I can see is that it appears to settle out a little less. I was always taught that clay is needed to suspend things, every thing else will settle out like a rock if there is no clay present in the slurry. Of any material, this is one that I would have expected to settle out the fastest.

The silica pants of this cone 10R mug have fallen down!

This picture has its own page with more detail, click here to see it.

This stoneware mug was glazed inside and halfway down the outside with pure silica. At some point during heatup the outside layer, not shrinking like the piece, simply fell down. And was sintered enough to hang together and remain intact through the rest of the firing (on the inside, the shrinking forced the silica to flake off into a pile at the bottom). Cone 10 has sintered the silica enough that it will not slake in water but it is fragile and soft and must be handled carefully.

What would happen if you made a clay body from 50:50 kaolin and ball clay?

This picture has its own page with more detail, click here to see it.

It would craze glazes! Really badly (this is fired at cone 6). One might think that there is adequate quartz in this high of a percentage of ball clay to at least minimize crazing, even causing shivering. At cone 10 oxidation this has about 5% porosity (the ball clay contributes enough iron that porosity drops to 2% in reduction). While an addition of feldspar would cut this somewhat, only more silica will increase thermal expansion enough to put the squeeze on glazes to prevent crazing like this.

Links

| Materials |

Flint

|

| Materials |

Crystalline Silica

|

| Materials |

Glass Sand

|

| Hazards |

Quartz Toxicity

Extended exposures to lower concentrations or less frequent exposures to higher concentrations can cause silicosis. |

| Hazards |

Silicosis and Screening

SILICOSIS and SCREENING by Edouard Bastarache |

| Hazards |

Dealing With Dust in Ceramics

A checklist for changes and additions to your tools and equipment and suggestions for habit you need to develop to control dust in your workplace. |

| Typecodes |

Generic Material

Generic materials are those with no brand name. Normally they are theoretical, the chemistry portrays what a specimen would be if it had no contamination. Generic materials are helpful in educational situations where students need to study material theory (later they graduate to dealing with real world materials). They are also helpful where the chemistry of an actual material is not known. Often the accuracy of calculations is sufficient using generic materials. |

| Typecodes |

Silica/Quartz

Quartz is very abundant and there are many grades and name brands. |

| Minerals |

Quartz

Quartz is the most abundant mineral on earth, it is the main crystalline mineral form of silica (SiO |

| Minerals |

Chalcedony

A cryptocrystalline form of silica. |

| URLs |

http://en.wikipedia.org/wiki/Silica

Silica at Wikipedia |

| URLs |

https://digitalfire.com/4sight/datasheets/SDSUSSilica.pdf

SDS US Silica |

| Oxides | SiO2 - Silicon Dioxide, Silica |

| Articles |

Formulating a Porcelain

The principles behind formulating a porcelain are quite simple. You just need to know the purpose of each material, a starting recipe and a testing regimen. |

Data

| Frit Softening Point | 1723C |

|---|---|

| Density (Specific Gravity) | 5.20 |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy