| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Tuning the degree of gloss on a matte black glaze

These 10-gram balls were fired and melted down onto a tile. The one on the left is the original G2934 Plainsman Cone 6 magnesia matte with 6% Mason 6600 black stain. On the right, the adjustment has a 20% glossy G2926B glaze addition to make it a little less matte. Notice the increased flow (the ball has flattened more) with the addition of the glossy. In addition, while the percentage of stain in the one on the right is actually less (because of the dilution of the transparent), the color appears darker! Tuning the degree of matteness when making color additions is not just for appearance, for functional ware it is also about achieving a surface that does not cutlery mark and is not leaching heavy metals.

Related Pictures

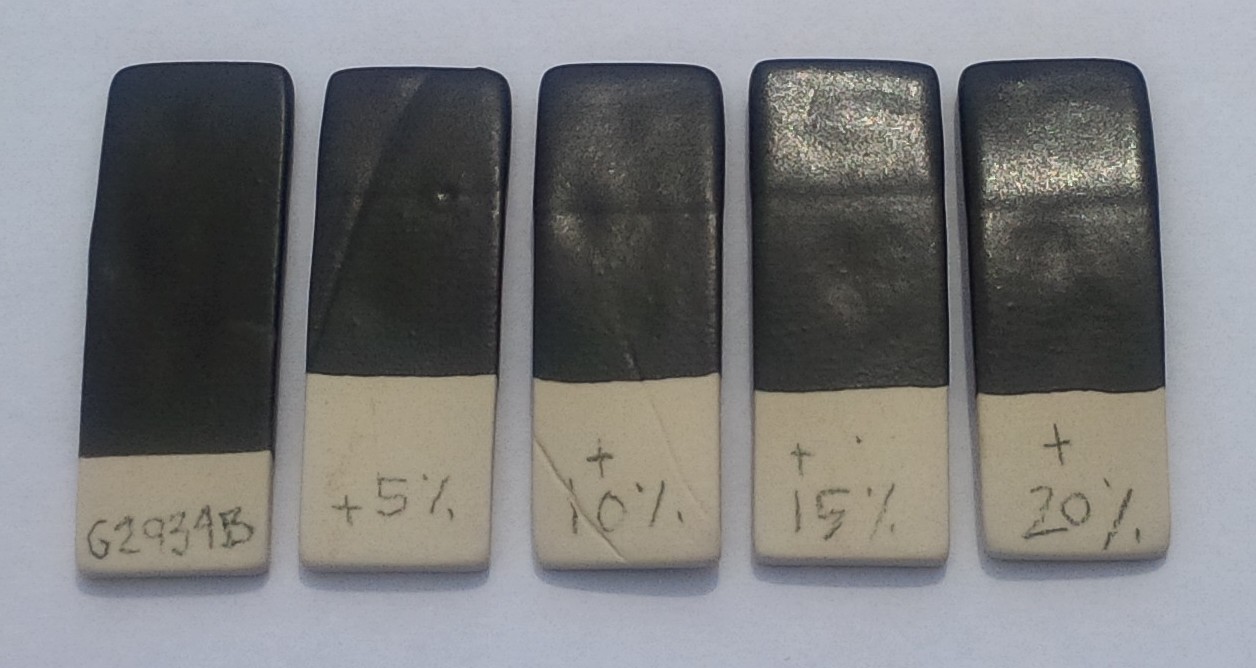

Tuning the degree of gloss in a colored matte glaze

This picture has its own page with more detail, click here to see it.

Matte glazes have a fragile mechanism. That means the same recipe will be more matte for some people, more glossy for others (due to material, process and firing differences). In addition, certain colors will matte the base more and others will gloss it more. It is therefore critical for matte glaze recipes to have adjustability (a way to change the degree of gloss), both for circumstances and colors. This recipe is Plainsman G2934 base matte with 6% Mason 6600 black stain added. It has been formulated to be on the more matte side of the scale so that for most people a simple addition of G2926B (M370 transparent ultra clear base recipe) will increase the gloss. That means users need to be prepared to adjust each color of the matte to fine-tune its degree of gloss. Here you can see 5:95, 10:90, 15:85 and 20:80 blends of the matte:gloss recipe bases.

The matteness of this glaze depends on the cooling rate

This picture has its own page with more detail, click here to see it.

This is the G2934Y matte cone 6 recipe with a red stain (Mason 6021). The one on the left was fired using the C6DHSC slow-cool schedule. The one on the right was fired using the drop-and-soak PLC6DS schedule. The only difference in the two schedules is what happens after 2100F on the way down (the slow-cool drops at 150F/hr and the other free-falls). For this glaze, the fast cool is much better, producing a silky pleasant surface rather than a dry matte.

Tune your glaze to the degree of matteness you want

This picture has its own page with more detail, click here to see it.

G2934 is a popular matte for cone 6 (far left). The mechanism of the matteness is high MgO content (it produces a more pleasant surface that cutlery marks and stains less than other mechanisms such as crystallization). But what if it is too matte for you? This recipe requires accurate firings, did your kiln really go to cone 6? Proven by a properly set firing cone? If it did, then we need plan B: Add some glossy to shine it up a bit. I fired these ten-gram GBMF test balls of glaze to cone 6 on porcelain tiles, they melted down into nice buttons that display the surface well. Top row proceeding right: 10%, 20%, 30%, 40% G2926B added (100% far right). Bottom: G2916F in the same proportions. The effects are similar but the top one produces a more pebbly surface.

Two cone 6 black glaze recipes I control and adjust

A gloss and a matte based on two reliable base recipes

This picture has its own page with more detail, click here to see it.

The clay is Plainsman M370. Fired at cone 6 using the PLC6DS drop-and-hold firing schedule. The inside glossy glaze is G2926BL. The outside glaze base is G2934BL matte. Both recipes contain 6% Mason 6600 black stain. G2934 is tricky to keep consistent because the matte surface is a product of both the chemistry and the firing schedule. Thus, we faced lots of testing when it became necessary to substitute Ferro Frit 3124 for the supposed equivalent, Fusion Frit F-19. Early results showed a little better melting, so the 10-15% glossy we normally add to move the stony matte toward satin is not needed. However, we still made an 85:15 batch for our more frequent slow-cool C6DHSC firings (otherwise this G2934 mug would have fired too matte). So with the two recipes and two schedules, I can produce four surfaces, from gloss satin to stony matte. Digitalfire was the first online source of a matte black functional glaze with tunable matteness.

What if G2934 fires too glossy, how can you increase matteness?

This picture has its own page with more detail, click here to see it.

Typically the G2934 cone 6 magnesia matte recipe fires with a surface that is too matte for functional ware (with cutlery marking and staining problems). This is intentional - it enables users to blend in a glossy base transparent to tune the degree of matteness. However, we have seen variation in the Ferro Frit 3124, serious enough that a recent production batch of glaze came out glossy (upper left in this picture)! This happened despite a C6DHSC slow cool firing. Shown here is a trial with additions of 4% calcined alumina (upper right) and 6 and 8% (bottom). All of these were too matte (1.5% turned up to be good). Although the slow-cool C6DHSC firing is the likely reason for the opacity here, opacity disruption still turned out to be a factor for stain additions (muting the colors slightly) even in faster cool firings. This is a testament to the critical chemistry balance that produces this matte surface. And the need to have adjustment options when inevitable variation occurs. Of course, it is important to use ultra-fine alumina (e.g. 400 mesh) to assure it will dissolve in the melt.

Videos

Links

| Glossary |

Triaxial Glaze Blending

In ceramics many technicians develop and adjust glazes by blending two, three or even four l materials or glazes together to obtain new effects |

| Glossary |

Matte Glaze

Random material mixes that melt well overwhelmingly want to be glossy, creating a matte glaze that is also functional is not an easy task. |

| Materials |

Mason 6600 Black Stain

A cobalt-containing stain useful in bodies, engobes and glazes at a wide range of temperatures. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy