| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

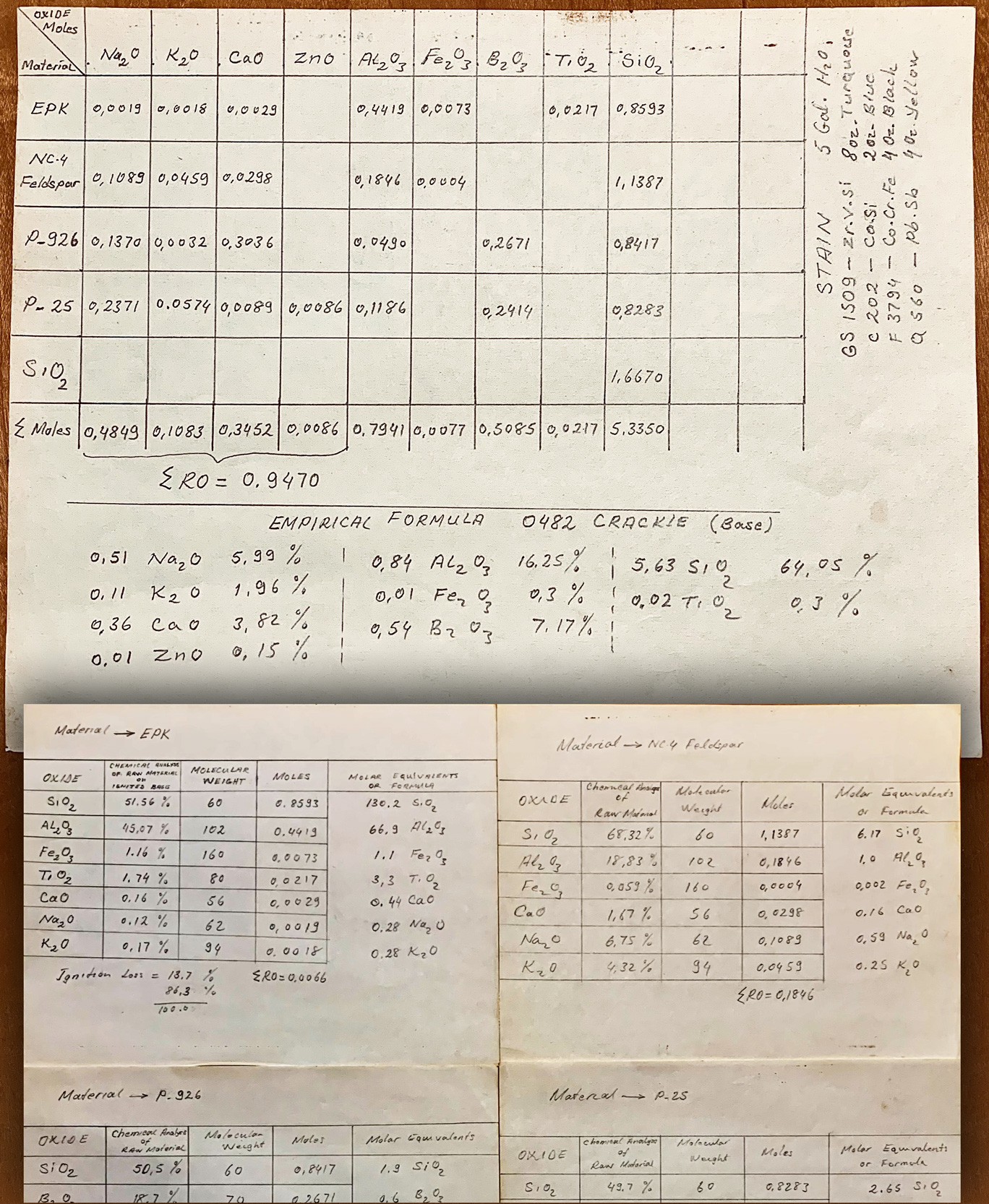

Glaze calculation in the 1960s

This batch-to-formula calculation was done by Albert E. Holthaus at Modern Art Products Company in Kansas City, MO (during the 1960s). Doing this not only seems quaint today, but suppliers put up roadblocks to doing it.

Notice that he took the manufacturer-supplied percentage analysis for each material (bottom) and calculated the unity formula for use in his batch to formula calculation (top). The recipe material weight amounts are missing in the latter; this appears to be his effort to create a documentation page of the recipe on the oxide formula level (this is what mattered to him). It was a time when frit formulas were published by their manufacturers. He also calculated the glaze's chemistry as a percentage analysis, likely to lay a basis to assess it against stated requirements from stain suppliers (certain stains only work when the host glaze chemistry meets a certain profile).

Doing this now is so much simpler. But almost no one actually does! The closest most technicians get to oxide formulas is choosing a frit from a list of ones for which the chemistry given by the manufacturer is only approximate.

Related Pictures

Retro glaze chemistry calculation - 1980

This picture has its own page with more detail, click here to see it.

I did this batch-to-formula glaze chemistry calculation on a version of Desktop Insight that ran on the TRS-80 Model I that I used at home (shown here is my Model III at work, running Insight). The TRS-80's were the first popular consumer micro-computers for business. Notice the report only uses capital letters, that machine did not support lower case! The dot matrix printers of the time lasted forever on an ink ribbon. Fanfold paper fed from a box, I could tear off only as much as was needed for a report. Boot time was less than 5 seconds. Here is what is amazing: In 2021 I found this same recipe in my Insight-live account (the green screenshot)! The results are a little different, I had the chemistry of talc wrong in 1980. I have always maintained my records on computer and through the years, as I migrated from one system to another, I wrote code to carry the data forward. This machine was advanced, before this I was storing data on cassette tape.

The Heartbeat of the Kiln: The Indispensable Plant Technician

This picture has its own page with more detail, click here to see it.

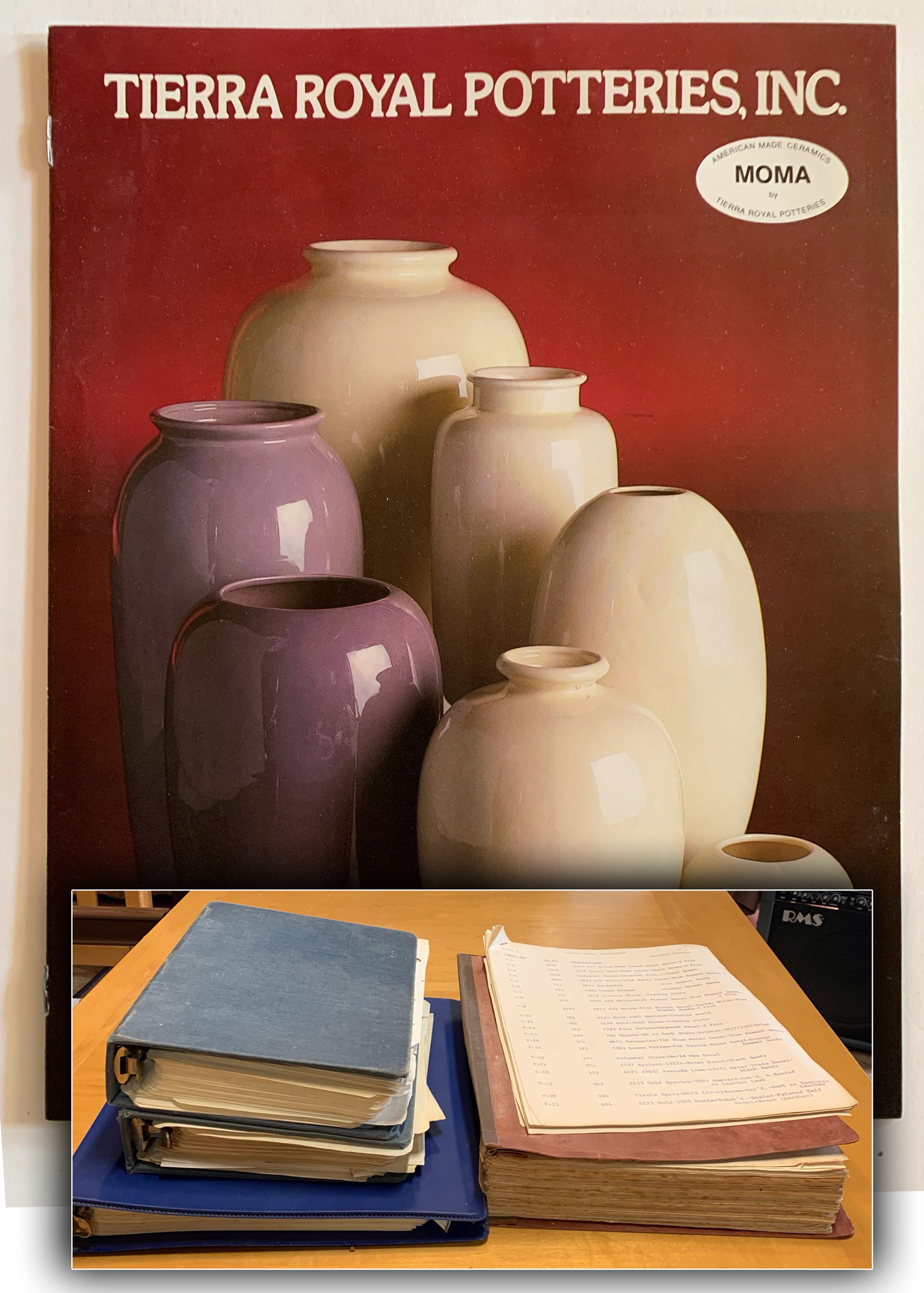

This page is dedicated to the skill and intuition of the Plant Technicians who kept the ceramic industry in North America thriving before the 1980s. Before we started clicking buttons to outsource things. They weren’t “role fillers” supplied by HR, they were “believers”. They understood everything in the plant; the equipment, processes, procedures, materials, recipes, kilns and firing. Managers set the pace, but the technicians made the pace possible. It was a time of local knowledge and company loyalty. They weren't temporary consultants or voices on a helpline; they owned and solved the problems. They were also mentors who passed their knowledge down.

These binders hold 40 years of recipes and techniques, kept by Albert E. Holthaus at Modern Art Products and Tierra Royal Potteries. Men like him were a legacy; they were the true "operating system" of a golden age of independence. They ensured the wheels kept turning, the fires kept burning and the quality kept enduring.

Danny Downsized: He's Being Outsourced.

He should have seen this coming!

This picture has its own page with more detail, click here to see it.

Management now thinks they can outsource his technical work. Danny was good, but he didn’t build a centralized, searchable record of material testing, shipment histories, specs, procedures, production problems, and solutions. Instead, his knowledge is buried in thousands of Excel and Word docs and PDFs. He should have used Insight-Live.com to organize, interlink, and preserve this critical data. Sadly, the company does not even realize what they face without Danny:

- Slower problem-solving and loss of institutional memory.

- Greater dependency on outsiders who lack long-term investment.

- Inability to verify product claims.

- Quality drift leading to recalls, rework, and higher warranty costs.

- Innovation slowdown.

- Eroding customer trust and ballooning consultant costs.

Had Danny been not just a watchdog but a technical innovator, suppliers and consultants would have been secured to support—not replace—his in-house expertise.

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy