| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Getting a chemical analysis of your ceramic powder

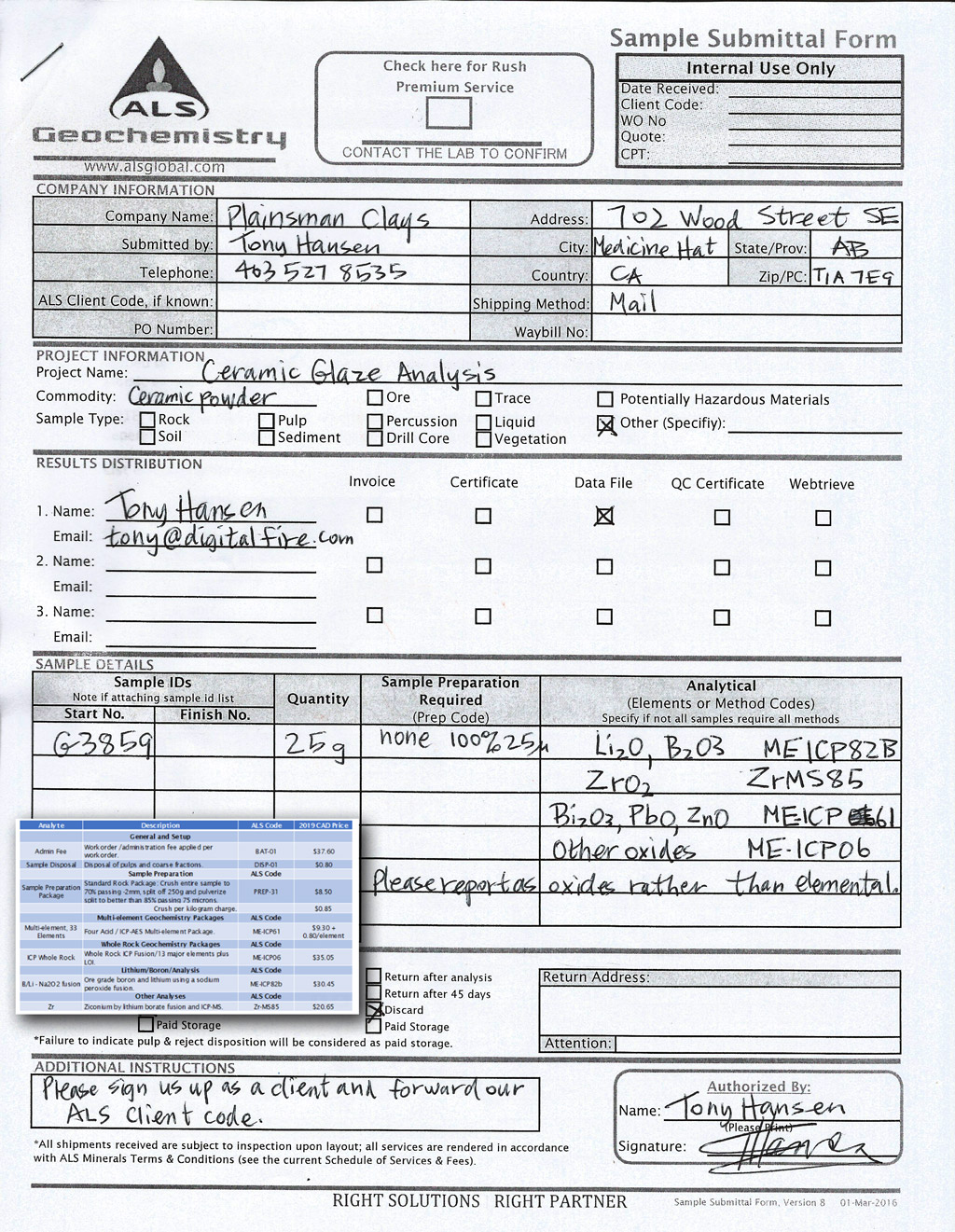

I have 200 mesh powdered samples of ceramic glazes, mixes of minerals and man-made glasses. I need to know the percentages of B2O3, ZnO, Li2O, BaO, Bi2O3, MgO, CaO, Na2O, K2O, PbO, P2O5, SrO, ZrO2, Al2O3, SiO2 (some of these might not be present).

Related Pictures

How to reverse-engineer a commercial transparent glaze

This picture has its own page with more detail, click here to see it.

The commercial cone 04 clear brushing glaze (on the left) works really well on our clay bodies so I sent it away to be analyzed (about $130). That revealed high Al2O3/SiO2 levels, this explains its resistance to crazing on our clay bodies and, even better, indicates high durability. In my account at insight-live.com I was able source the same chemistry from two Fusion frits (plus a little kaolin and silica). The melt fluidities are almost identical (my G3879 has a little more surface tension). I needed to make a dipping glaze version and chose a method that would produce a thixotropic slurry. One caution: An assay lab cannot analyze the complexities of a colored glaze, instead focus on the base clear and add stains to that. The first two-gallon bucket made saved the development cost plus more! And knowing the recipe made it possible to adjust for even lower thermal expansion. Another plus: I can now make my own low SG or high SG brushing version.

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy