| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Regular bottles of beer looking humble beside the ceramic one

This is v2 ceramic beer bottle in a common-sized 6-pack case. Of course, our case will have our logo and artwork. I paid $19 for it. They threw in the bottles of beer for free! That is a ceramic bottle that has bumped out the ordinary glass one and is showing off its size and superior character. But it is a tight fit in this case - it appears to be 4mm too large in diameter. I am sworn not to have another beer until it is served in a proper ceramic bottle like this. So if you live in my home town and want those six unneeded bottles, let me know.

Related Pictures

The bottle is more important than the beer!

This picture has its own page with more detail, click here to see it.

What is depicted here doesn't happen with ceramic beer bottles. They do the talking. They talk about how we should be manufacturing our own stuff locally. They remind us that we make beer here so we should also make the bottles. They tell us we should take pride in things we can manufacture ourselves. That we should use local raw materials rather than importing them. Glass bottles are just a container, ceramic bottles elevate beer, they bring sustainability and style to beer drinking. Ceramic bottles bring local craftsmen to your beer experience - potters can make them. Ordinary glass will always be just ordinary glass, but ceramic bottles bring a world of aesthetic possibilities to this basic part of our culture.

This GA6-B glaze is better than beer bottle glass

This picture has its own page with more detail, click here to see it.

Ceramic glazes, like this GA6-B, are actually just glass. But they are not like bottle glass. The latter is formulated to work well in forming machines (harden quickly), melt and stiffen quickly, have low melt viscosity and resist milkiness and crystallization on solidification. The chemistries to accomplish this have adequate resistance to leaching and adequate durability for a few uses. A stoneware glaze melt needs to be much more viscous (to stay put on vertical surfaces). And, it must have a lower thermal expansion (to match common clay bodies). And, it must resist crystallization much more (since it cools slowly). Fortunately, meeting these needs brings along big benefits: Greater durability, hardness and resistance to leaching. Stoneware glazes and bottle glass share a common trait: They have about the same amount of SiO2. But the similarity ends there, stoneware glazes have:

-High Al2O3. Three to five times more! It is the key oxide for durable glass. And it stiffens the melt (that disqualifies high levels from bottle glass).

-The same fluxes (CaO, MgO, K2O, Na2O). But they distribute very differently (half the CaO, half to one third the KNaO, much more MgO). Other fluxes like SrO, Li2O are also common.

-Low KNaO (which they call R2O). In glazes, it produces crazing, 5% is a typical maximum. But bottle glass can have double or triple that (the high thermal expansion is not an issue, and its cheap source materials supply lots of melting power).

-B2O3 melter. It is expensive but can be justified because the glaze is just a thin layer. Glazes at the low end of the stoneware range have 5% or more boron.

Far right: A glass bottle. Left: Small test bottles made from dark and light burning stonewares. Third: A production ceramic bottle. Notice how much the dark body darkens the GA6-B glaze.

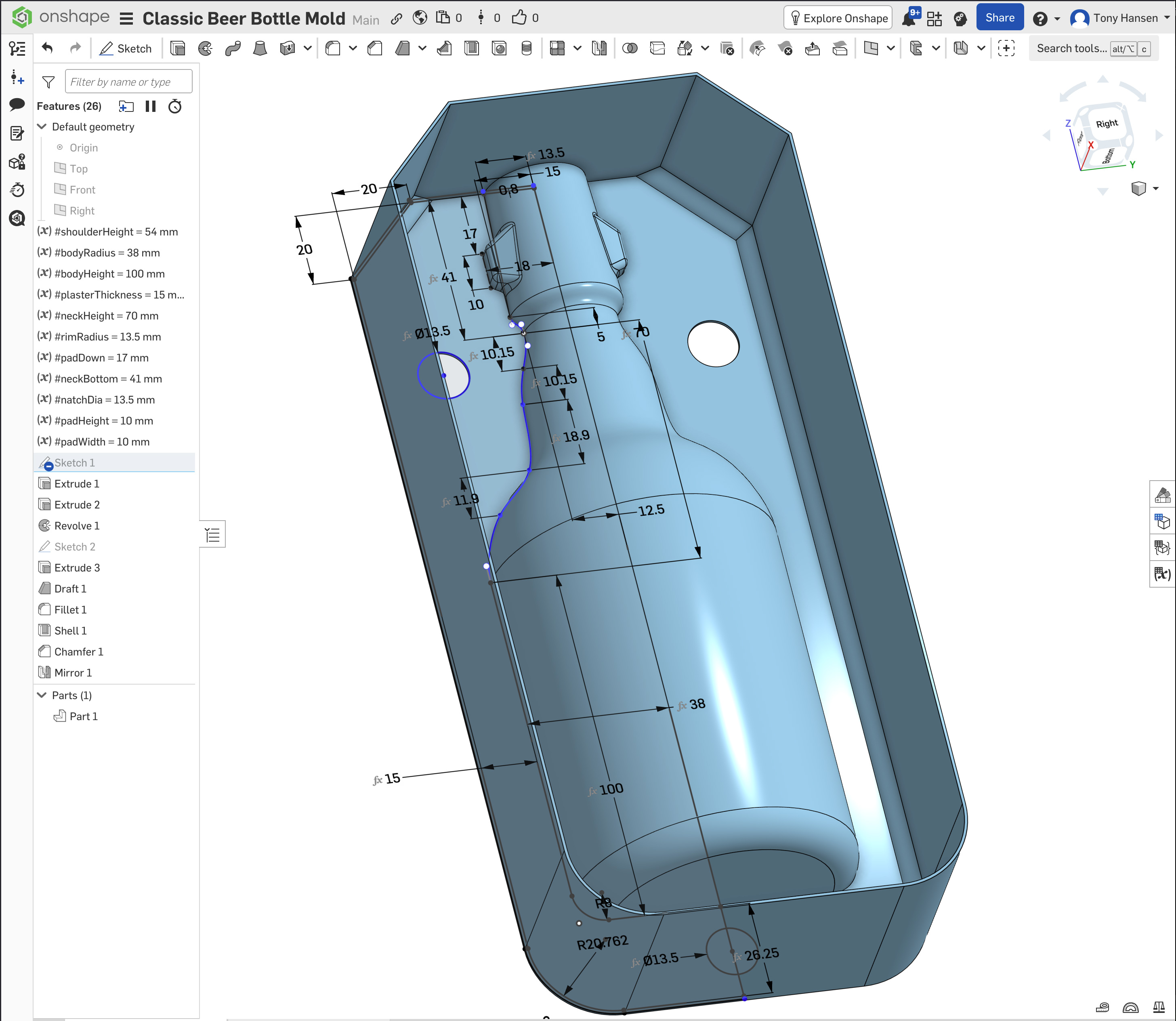

v7 Classic beer bottle mold in OnShape

Make authentic-looking beer bottles that are better than glass

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

The slip casting process is so much more accessible than in the past because of 3D printing. Why not start with this? This bottle has all the same dimensions as my v6 (done in Fusion 360). But, because this is done in OnShape, one click here opens it directly in a browser window with all the power of a professional CAD system. If you have a free account there and are logged in, one more right-click can export it in 3MF or STL format for 3D printing. Or a "Copy Workspace" menu choice will move it to your account to enable editing and setting variables, adjusting the shape, etc. This works in your browser, there is no software to install and OnShape is free for hobbyists. This mold works with my pour spouts (no spare is needed) and natch system (no registration keys are needed). So just insert the clips and embeds, pour in plaster, remove the PLA plastic with a heat gun and you have a working mold. When dry, glue in the natches, attach a spout (using slip) and fill the mold with casting slip.

Need a stoneware slip casting recipe? L4768E or L4768H are a good choice. A glaze recipe? How about GA6-B (or similar)? Go full DIY with this, you will never turn back. Need a guided help to make this happen? Sign up for an Insight-live.com group account and we can work together to make this happen for you.

Videos

Links

| URLs |

https://bottles.beer

Say goodbye to ordinary glass and elevate beer with ceramic bottles. The second one is glass. The others are durable stoneware. They keep your beer colder longer. They are refillable and safer when broken. Our bottles will be crafted by local artisans, bringing sustainability and style to your beer experience. Partnering with Digitalfire.com we will also help other potters and small manufacturers make them. |

| Projects |

Beer Bottle Master Mold via 3D Printing

A project that took several years of failures and blind allies and is finally coming together - so much simpler than expected! |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy