| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Danny Downsized: He's Being Outsourced.

He should have seen this coming!

Management now thinks they can outsource his technical work. Danny was good, but he didn’t build a centralized, searchable record of material testing, shipment histories, specs, procedures, production problems, and solutions. Instead, his knowledge is buried in thousands of Excel and Word docs and PDFs. He should have used Insight-Live.com to organize, interlink, and preserve this critical data. Sadly, the company does not even realize what they face without Danny:

- Slower problem-solving and loss of institutional memory.

- Greater dependency on outsiders who lack long-term investment.

- Inability to verify product claims.

- Quality drift leading to recalls, rework, and higher warranty costs.

- Innovation slowdown.

- Eroding customer trust and ballooning consultant costs.

Had Danny been not just a watchdog but a technical innovator, suppliers and consultants would have been secured to support—not replace—his in-house expertise.

Related Pictures

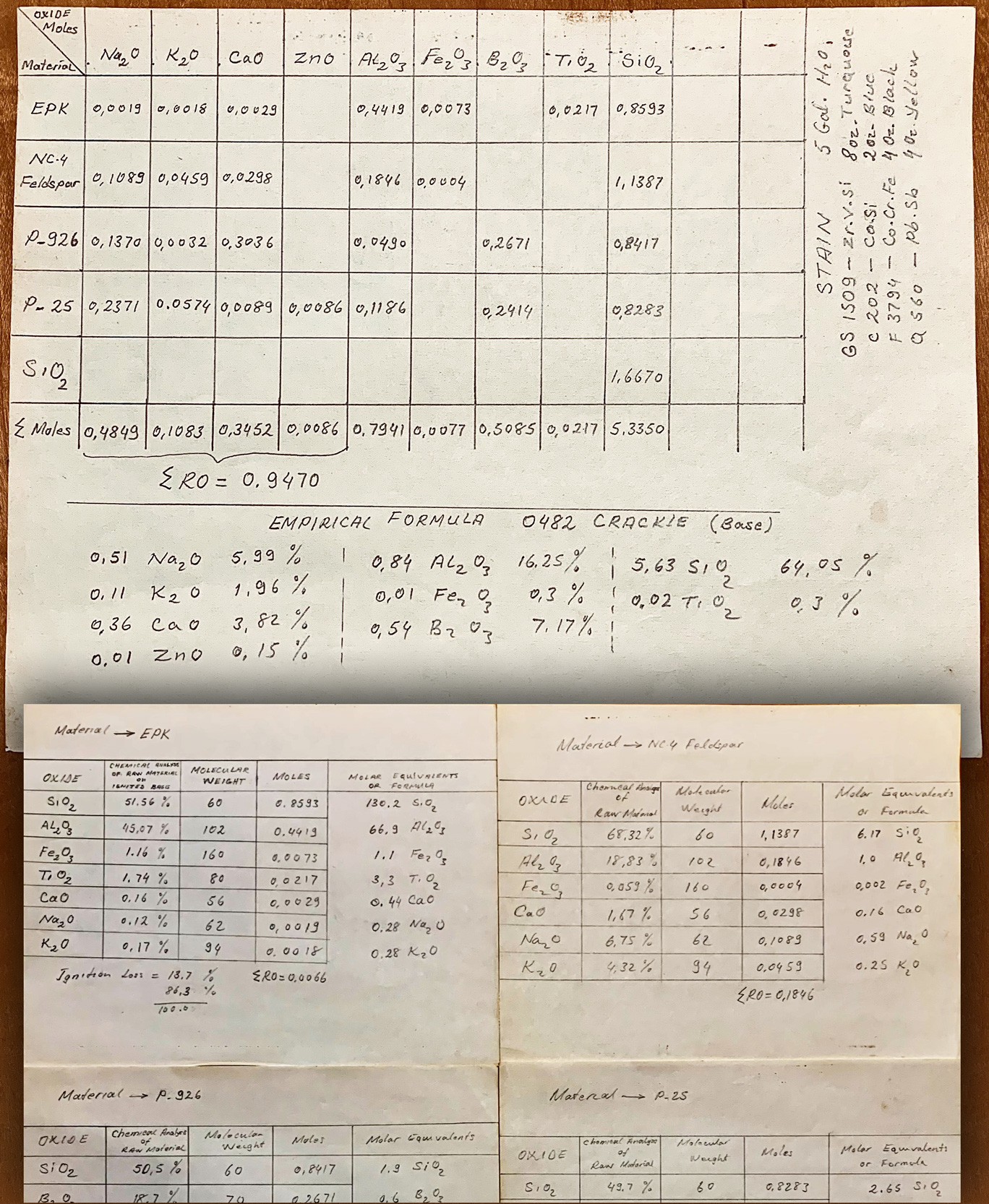

Glaze calculation in the 1960s

This picture has its own page with more detail, click here to see it.

This batch-to-formula calculation was done by Albert E. Holthaus at Modern Art Products Company in Kansas City, MO (during the 1960s). Doing this not only seems quaint today, but suppliers put up roadblocks to doing it.

Notice that he took the manufacturer-supplied percentage analysis for each material (bottom) and calculated the unity formula for use in his batch to formula calculation (top). The recipe material weight amounts are missing in the latter; this appears to be his effort to create a documentation page of the recipe on the oxide formula level (this is what mattered to him). It was a time when frit formulas were published by their manufacturers. He also calculated the glaze's chemistry as a percentage analysis, likely to lay a basis to assess it against stated requirements from stain suppliers (certain stains only work when the host glaze chemistry meets a certain profile).

Doing this now is so much simpler. But almost no one actually does! The closest most technicians get to oxide formulas is choosing a frit from a list of ones for which the chemistry given by the manufacturer is only approximate.

Protect your reputation as a clay body manufacturer.

Unready Freddie is not monitoring incoming clays!

This picture has its own page with more detail, click here to see it.

A kaolin shipment just came in. "UnReady Freddie" is panicking. He thinks he remembers that products made with the last shipment were lacking plasticity and the fired color was off. He is going to have to come up with different lame excuses for complaining customers this time.

"Ready Freddie" has Insight-Live and has collected years of data on incoming shipments in one searchable place. He knows what to check on each and has fired bars, in-mix tests, particle size checks, data sheets, lots of pictures, notes, etc. He also has traceability - he knows what material batch went into what product. He works with production to do material lot tracking and with purchasing to keep suppliers aware he is testing. Because Ready Freddie knows how materials vary he can compensate recipes and processes so customers see a consistent product.

UnReady Freddie has a few spreadsheets somewhere. But he is busy with other things. Who do you want in charge of product consistency (and company reputation)? Here is what to do next: Have your technician study the page "Testing a New Load of EP Kaolin" (link below). You will be hearing from him/her soon.

20 Skids of Material Just arrived

Fatique Freddie is overwhelmed!

This picture has its own page with more detail, click here to see it.

He is the lone quality technician, part time. Incoming materials properties keep changing, but management pretends they aren't. Freddie is tired of dealing with what could be lurking in these pallets—grit and fired specks, drying cracks, warping, blistering - he's flying blind. It’s just a matter of time before something fails… and his name is on it! But there is a way to start "owning the problem" by starting QC small (using Insight-live):

-Number the pallets with a big marker.

-Add a new record in Insight-live, assign a new code number and date and link it to a specification.

-In the notes, log lot numbers from the bags and any pertinent details (e.g. supplier invoice, PO#).

-Upload supplier certificate photos.

-Grab samples through the bag spouts— one per lot or pallet.

-Do testing for oversize particles (especially in clays).

-Make SHAB test bars (for clays). Dry them in a dehydrator and fire them overnight (because production wants to start using this tomorrow!).

-Snap close-up photos of the fired bars and upload and annotate them for future comparison.

This is survivable QC. It won’t fix everything. Now he is Ready-Freddie, with a solid plan to stand on when the blame starts flying. Maybe he will even be able to establish coordination between sales, production, and QC (using a group account) and even refine the specifications and procedures for each material type.

Tommy Turnback Ignored AI

By not adapting he wrote his own layoff notice

Made using a simple prompt at ChatGPT.

Made using a simple prompt at ChatGPT.This picture has its own page with more detail, click here to see it.

Management says AI can do most of the technical work now. Tommy had no automation, no models, no data pipelines. Just “the way we’ve always done it,” trapped in spreadsheets and sticky notes. When the new AI system went live, his expertise didn’t plug in. It got left behind!

- The AI could really have used his seasoned human oversight.

- Years of hard-won knowledge lost in a digital junk drawer.

- Outside consultants are charging a premium to relearn what he already knew.

- Errors slip through because no one taught the machines better.

- Innovation stalls while the company rebuilds what he could have bridged.

Technicians aren’t just there to keep things running—they should teach the future how to work. Refusing to adapt doesn’t protect your job. It writes your own pink slip.

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy