| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Glaze Recipes

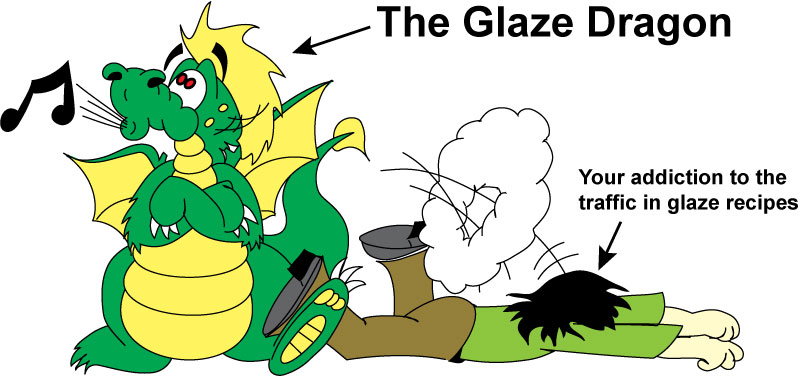

Stop! Think! Do not get addicted to the trafficking in online glaze recipes. Learn to make your own or adjust/adapt/fix what you find online.

Key phrases linking here: glaze recipes - Learn more

Details

Warning about recipes that you find online: Be careful about wasting your time. And money. They are seldom what they appear in the pictures! You will find alot of frustration and end up with a stock of useless materials needed to try them. Better to have a few recipes you understand and can control than 50 renegades that fail a sanity check and put you through hell to just make them sometimes work!

Recipes are trafficked, often just taking space on web pages. People pass them around without a thought. They almost always have no documentation about the specific materials, methods and firing procedures needed to get the effect. The person posting them often does not even understand the mechanism. Special effect glazes almost always come at a cost (e.g. blistering, crawling, pinholing, shivering or just running off the ware).

But published recipes are often, very often, simply wrong. Bad. Evil! They are nonsensical, have wildly crazy chemistries and recipes, use dangerous or difficult materials, fire to leach-prone surfaces, craze badly on any body, cutlery mark or stain easily. Understanding glazes is better. Save yourself money and frustration. And don’t be so afraid of a little chemistry (e.g. viewing a glaze as a formula of oxides rather than a recipe of materials) that you miss out on a lot of control and potential.

Imagine being able to look at a recipe online, recognize its mechanism, then just transplant that into a base recipe you already have, one you understand and have perfected over time to work in your production, in your kiln and on your clay bodies.

Follow some of the links on this page and go down a road that will lead you somewhere good!

Related Information

Glaze recipes online waiting for a victim to try them!

This picture has its own page with more detail, click here to see it.

You found some recipes. Their photos looked great, you bought $500 of materials to try them, but none worked! Why? Consider these recipes. Many have 50+% feldspar/Cornwall/nepheline (with little dolomite or talc to counteract their high thermal expansion, they will craze). Many are high in Gerstley Borate (it will turn the slurry into a bucket of jelly, cause crawling). Others waste high percentages of expensive tin, lithium and cobalt in crappy base recipes. Metal carbonates in some encourage blistering. Some melt too much and run onto the kiln shelf. Some contain almost no clay (they will settle like a rock in the bucket). A better way? Find, or develop, fritted, stable base transparent glossy and matte base recipes that fit your body, have good slurry properties, resist leaching and cutlery marking. Identify the mechanisms (colorants, opacifiers and variegators) in a recipe you want to try and transplant these into your own base (or mix of bases). And use stains for color (instead of metal oxides).

Before spending time trying online recipes, take a minute to do a sanity check on them

This picture has its own page with more detail, click here to see it.

This is a cone 6 GLFL test to compare melt-flow between a matte recipe, found online at a respected website, and a glaze we use often. Yes, it is matte. But why? Because it is not melted! Matte glazes used on functional surfaces need to melt well, they should flow like a glossy glaze. Even though this recipe has 40% nepheline syenite, lots of dolomite and calcium carbonate it is not melting. Yes, these are powerful fluxes, but at cone 10, not cone 6! To melt a cone 6 glaze boron, zinc or lithia are needed. Boron is the most common and best general-purpose melter for potters (it comes mainly in frits, Gerstley borate). The concept of a limit recipe applies here, the idea of eye-balling a recipe and quickly assessing if it is ridiculous or not.

Why does this glaze look like this? What are its mechanisms?

This picture has its own page with more detail, click here to see it.

This is cone 6 an oxidation transparent glaze having enough flux (from a boron frit or Gerstley Borate) to make it melt very well, that is why it is running. Iron oxide has been added (around 5%) producing this transparent amber effect. Darker coloration occurs where the glaze has run thicker. These are all simple mechanisms, which, once understood, can be transplanted into other glazes. This glaze is also crazing. This commonly occurs when the flux used is high in K2O and Na2O (the highest expansion fluxing oxides). K2O and Na2O produce the brilliant gloss. They come from feldspars, nepheline syenite and are high in certain frits.

How do you turn a transparent glaze into a white?

This picture has its own page with more detail, click here to see it.

Right: Ravenscrag GR6-A transparent base glaze. Left: It has been opacified (turned opaque) by adding 10% Zircopax. This opacification mechanism can be transplanted into almost any transparent glaze. It can also be employed in colored transparents, it will convert their coloration to a pastel shade, lightening it. Zircon works well in oxidation and reduction. Tin oxide is another opacifier, it is much more expensive and only works in oxidation firing.

Tune your glaze to the degree of matteness you want

This picture has its own page with more detail, click here to see it.

G2934 is a popular matte for cone 6 (far left). The mechanism of the matteness is high MgO content (it produces a more pleasant surface that cutlery marks and stains less than other mechanisms such as crystallization). But what if it is too matte for you? This recipe requires accurate firings, did your kiln really go to cone 6? Proven by a properly set firing cone? If it did, then we need plan B: Add some glossy to shine it up a bit. I fired these ten-gram GBMF test balls of glaze to cone 6 on porcelain tiles, they melted down into nice buttons that display the surface well. Top row proceeding right: 10%, 20%, 30%, 40% G2926B added (100% far right). Bottom: G2916F in the same proportions. The effects are similar but the top one produces a more pebbly surface.

Reason 1 for record keeping in an insight-live.com account

This picture has its own page with more detail, click here to see it.

Notes. It is a much better place to take notes than that old binder you use. And the chance of losing them is the same as the chance of losing the phone that you access them with. No, wait, it is way less. Because any internet connected phone or device with a browser can be used.

Are your glaze recipes lost in binders or buried on your phone?

This picture has its own page with more detail, click here to see it.

Keeping your valuable notes, recipes, test results, pictures and notes in a three ring binder? Or are your pictures scattered across your phone with no keywords or context? If you're testing, adjusting, or developing glazes, bodies, underglazes, engobes, etc. for ceramics, traditional notebooks and binders could be holding you back. With Insight, you can link recipes to each other and to important details like photos, materials and firing schedules. Organize test recipes into projects, classify them, calculate chemistry, and create mix tickets. Research materials and perform keyword searches. Physical notebooks can’t do this—but your account at Insight-live.com can!

Reason 2 for record keeping in an insight-live.com account

This picture has its own page with more detail, click here to see it.

It is so much easier to print a mix ticket for whatever total you want. Resulting in fewer errors, more confidence in batches you have mixed.

Reason 3 for record keeping in an insight-live.com account

This picture has its own page with more detail, click here to see it.

Its cleaner! When you finish mixing a batch you can throw away the mix ticket. You will be printing another the next time. And likely to a different total.

A good matte glaze. A bad matte glaze.

This picture has its own page with more detail, click here to see it.

A melt fluidity comparison between two cone 6 matte glazes. G2934 is an MgO saturated boron fluxed glaze that melts to the right degree, forms a good glass, has a low thermal expansion, resists leaching and does not cutlery mark. G2000 is a much-trafficked cone 6 recipe, it is fluxed by zinc to produce a surface mesh of micro-crystals that not only mattes but also opacifies the glaze. But it forms a poor glass, runs too much, cutlery marks badly, stains easily, crazes and is likely not food safe! The G2934 recipe is google-searchable and a good demonstration of how the high-MgO matte mechanism (from talc) creates a silky surface at cone 6 oxidation the same as it does at cone 10 reduction (from dolomite). However it does need a tin or zircon addition to be white.

A flameware recipe. Are they kidding?

This picture has its own page with more detail, click here to see it.

This is made from a recipe promoted by a popular website (equal parts of talc, ball clay and grog). Are they serious? How could the page fail to mention how coarse this is? How is it possible to throw something like this. Wouldn’t ware be porous and weak? Is this an attempt to make cordierite? But that needs special firing. Maybe the idea is that anything with this much grog can automatically be ovenware!

Links

| Articles |

Why Textbook Glazes Are So Difficult

The trade is glaze recipes has spawned generations of potters going up blind alleys trying recipes that don't work and living with ones that are much more trouble than they are worth. It is time to leave this behind and take control. |

| Articles |

Concentrate on One Good Glaze

It is better to understand and have control of one good base glaze than be at the mercy of dozens of imported recipes that do not work. There is a lot more to being a good glaze than fired appearance. |

| Articles |

Where do I start in understanding glazes?

Break your addiction to online recipes that don't work or bottled expensive glazes that you could DIY. Learn why glazes fire as they do. Why each material is used. How to create perfect dipping and brushing properties. Even some chemistry. |

| Articles |

Trafficking in Glaze Recipes

The trade is glaze recipes has spawned generations of potters going up blind alleys trying recipes that don't work and living with ones that are much more trouble than they are worth. It is time to leave this behind and take control. |

| Glossary |

Limit Recipe

"Recipe logic" is the ability to sanity-check ceramic glaze recipes on sight, by noting that materials present and their relative percentages. |

| Glossary |

Variegation

Ceramic glaze variegation refers to its visual character. This is an overview of the various mechanisms to make glazes dance with color, crystals, highlights, speckles, rivulets, etc. |

| Media |

Enter a Recipe Into Insight-live

Learn how to add a recipe, title it, add lines and change them, set lines to added status, deal with unrecognized materials, enter notes and pictures and print a mix ticket |

| Media |

How to Paste a Recipe Into Insight-live

If your recipe is on the clipboard, this shows you how to import it into Insight-live and make adjustments after. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy