| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

v2.0 DIY Jiggering is Here!

Available as a Product on the Downloads page

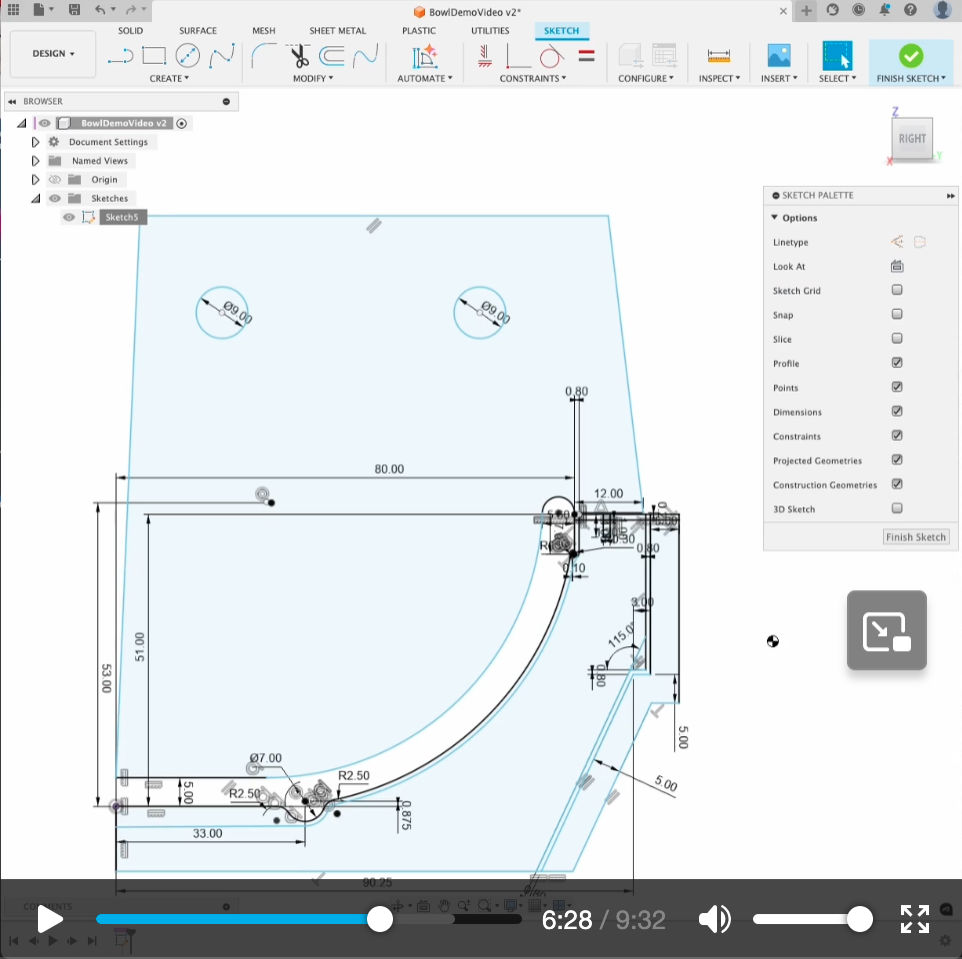

It is beyond amazing that this is possible at home now! Follow Lily, step-by-step as she uses Fusion 360 to create this mold, intended for use in a cuphead, in 9 minutes!

A newer larger 3D printer made this type of mold much more practical (and it adds the ability to make a clamping baseplate to enable a hyprid plaster/PLA master). This procedure will work for jiggering almost any closed shape. 3D print the shell mold for the outside shape of the bowl, cast a plaster model in it and tool and soap it for a perfect surface. Then, 3D print the shell of the outside of the jigger mold (full or flanged clamped halves). Invert both onto a clamping baseplate, stick the model down using a sticky clay slip and use the correct spacer ring to center the model inside the shell mold. Pour it full of plaster to make a working mold. Finally, adjust the hole locations on the template to mount on the jigger arm and 3D print it. You will be amazed at the cutting edge of the template, and the quality it can produce.

Available as a Product on the Downloads page

Related Pictures

3D-printed Mold for Giffin Jigger

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

This jigger mold-making method features a hybrid plaster form of the outside profile attached to a 3D-printed clamping baseplate. Clamp-on rails enable easy setup and extraction for mold production. Here are the steps:

-Download the drawing, edit the bowl profile and size (and the template) and then 3D-print the parts (typically using PLA filament). Print two rails.

-3D-print threaded anchors and attach them to the base plate.

-Center and clamp the spacer ring onto the flat side of the base plate.

-Set the model mold on a level surface, pour plaster into it (right to the rim), place the base plate (anchors down) onto it (being sure it seats down into the spacer ring to assure centering). The plaster should overflow up the air holes in the plate. Weigh it down and leave to set.

-Remove the mold (using heat gun if needed), finish the surface of the plaster (with a metal rib or 3D-print one with curves to match the contour) and soap it in preparation for pouring a working mold.

-Clamp the rails down to the base plate (using paper clamps), place the mold on a perfectly level surface and fill with plaster.

-Fit the template to your jigger arm (more than one cycle of editing the upper section and adjusting hole placement will likely be needed, so don't print it solid right away).

You now have a working jigger mold for use on a Giffin grip. Repeat the last step as many times as needed.

Creating a flange on a 3D printed two-half shell mold

This picture has its own page with more detail, click here to see it.

Upper left: If this mold is too big for a 3D printer or needs to be reusable then it must be printed in two halves (with flanges for clamping). Here is how to create the vertical flanges on the ends.

The secret is revolving twice, once with the wall and flange and a second time using a cut operation with only the flange.

Top right: The sketch is visible and includes both the 0.8mm wide mold wall (and top flange) and the vertical 5mm wide vertical flange.

Bottom left: Both flange and wall are being rotated as a new body 180 degrees (-180 for the back half).

Bottom right: The flange itself is being revolved with partial extent type, and from two sides, using the cut operation and from -179.3 to 0.7 degrees. How did I know these numbers? Experimentation. The Fusion 360 Inspect menu has a measure tool. I kept trying different numbers until I got a flange about 1.2mm wide.

This method could also be used for three or more pieces. Also for one piece that can be opened enough on one side to release (using an initial 359.5 degrees and that a second cut to leave the two flanges).

Videos

|

Designing a Jigger Mold for a Bowl Using Fusion 360 CAD

From scratch we will create a sketch, constraining as we go, of everything needed to be able to revolve 3D shapes to cast a model of the outside shape of the bowl, a mold to cast the plaster jigger mold around it, a spacer ring to line them up concentrically and the template to bolt to the jigger arm. Every single step is covered so that potters or even hobbyists can do this. A landing page at digitalfire.com is the gateway to everything you need to know to start jiggering on a small scale. |

Links

| Glossary |

Jiggering

Jiggering is a process of forming pottery that employs a spinning plaster mold and a tapered template to press soft clay or porcelain against it. |

| Projects |

A cereal bowl jigger mold made using 3D printing

A new way to 3D-print your way to making jigger molds and templates. The molds are encased in a 3D printed shell that makes them fit perfectly into the cuphead. And the template is precise and very effectivwe. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy