| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

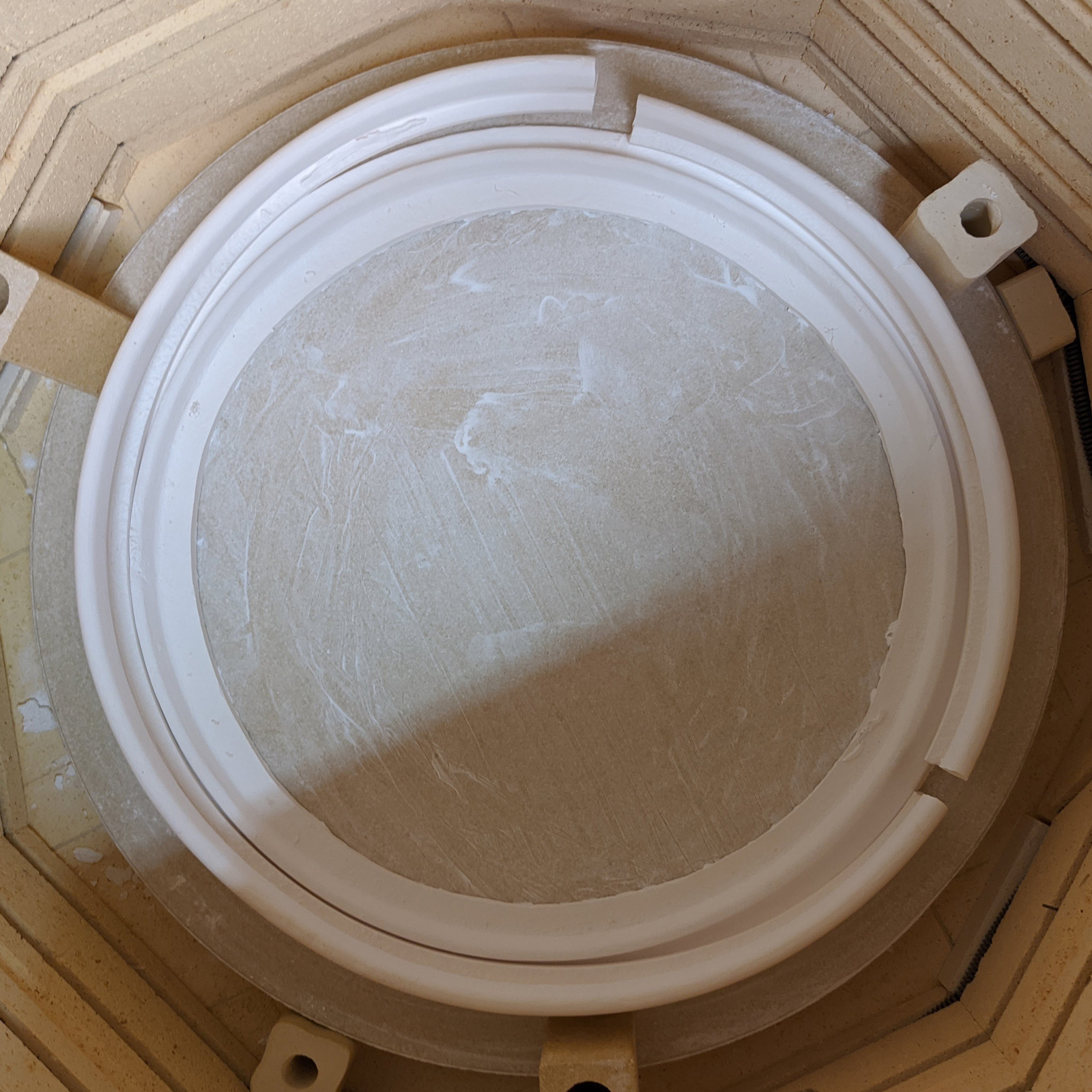

Firing an impossible-to-fire piece was possible!

These porcelain pieces were cracking, even during very slow firings at cone 03. The radiant heat from the elements heated the outside edge first, creating a temperature gradient. That produced a firing shrinkage gradient that the piece could not absorb. Even with very slow firings and various other strategies, the potter could not solve the problem. So is it really true that anything can be fired if you can do it slow and even enough? Yes, even this. Three factors made it possible: 1) The low firing temperature. 2) Even slower firing speed (24 hours instead of 12 hours to ramp). 3) Elimination of the direct radiant heat. This clever potter fires using only the elements in the bottom one/third of the kiln (the top 2/3 elements never go on) and puts the rings only in the top 2/3 of the kiln. Again, that was possible because it is only a cone 03 firing.

Videos

Links

| Glossary |

Kiln Firing

All types of ceramic are fired in a kiln to cement particles together to produce a hard and water and temperature resistant product. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy