| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

DIY natches, spacers and embeds in a plaster handle mold

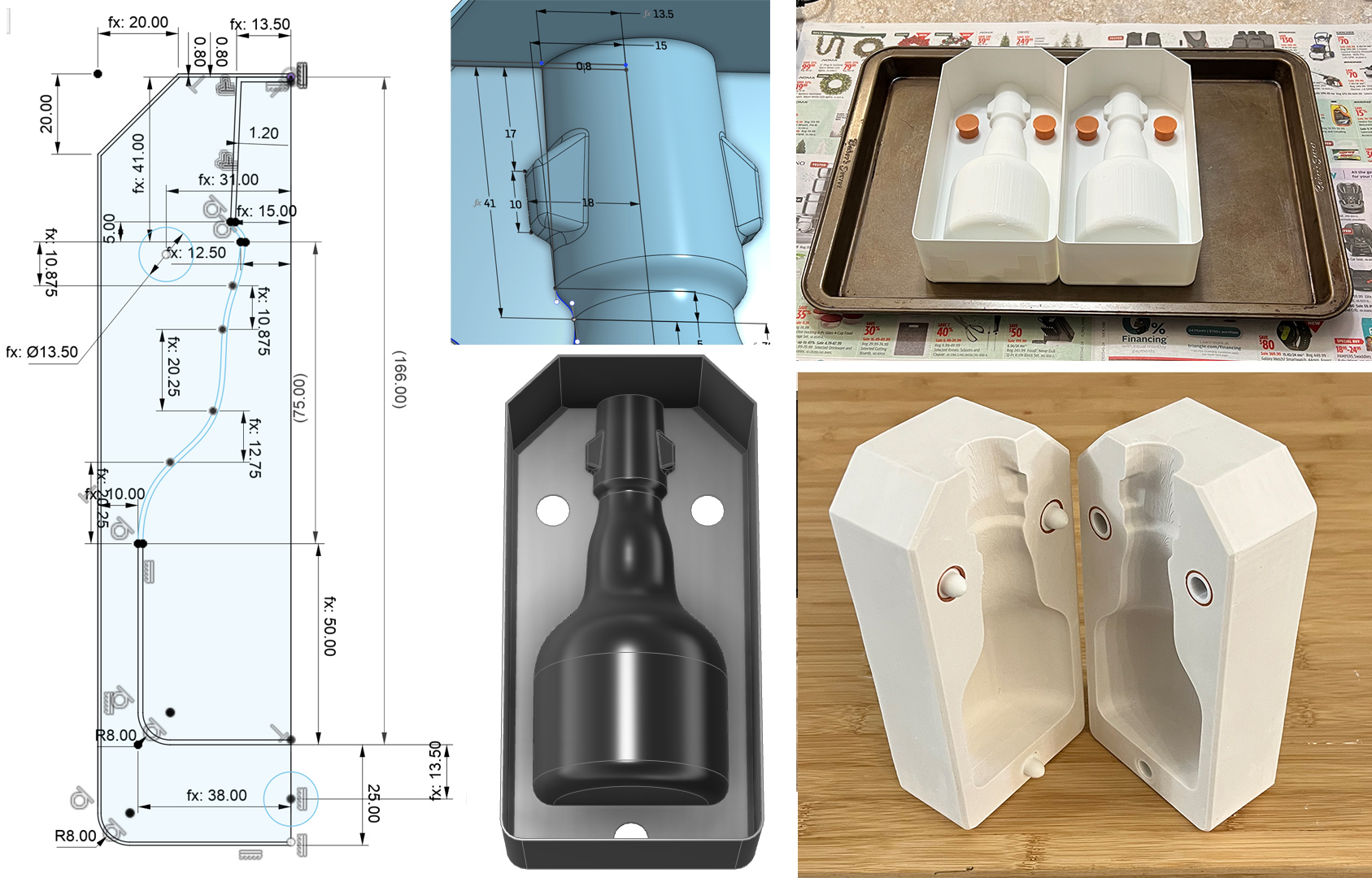

This is our third-generation alternative to the use of traditional mold natches (like the red ones in the photo). Here is what you are seeing:

Right: A 3D-printed case mold for a mug handle. Clips (retainers) have been inserted from the bottom side. An embed has been pushed down over the one in the rear.

Center: The plaster mold created from it. The embed at the rear is ready for inserting a spacer (the nipple of the other half will it into that). A natch has also been inserted into the embed in the front. These fit tight enough in the hole that glue was not needed here.

Left: Spacers have been inserted into both embeds. A standard natch fits into the one in the rear and one of our natches fits into the one in the front.

Soon the CAD drawing for these (natches, spacers, embeds, clips) will be available on digitalfire.com.

Related Pictures

v1 DIY Four-Part Mold Natch System

Essential for 3D mold-making in ceramics

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

Plastic natches are used in traditional mold making for slip-cast ceramics (instead of registration keys). They are cast into plaster molds to provide durable and good-fitting interlocks between pieces. They are self-interlocking, a popular size is the 3/8" or 9.5 mm (nipple diameter) natch. However, these have not proven suitable for the mold making process described on this site. The Digitalfire four-part system accommodates 3D printing (usually using PLA filament) case molds for pouring plaster, block molds for pouring rubber case molds and even hybrid solutions. Here are some features of our system:

-13.5mm holes in 3D printed case molds are all that is needed to adapt to these.

-3D printing case and block molds necessitate pouring plaster and rubber into shells with planar mating surfaces downward that must sit flat on the work table (traditional natches don’t work in this setting).

-Casting an embed into a mold enables gluing (or friction fitting) a natch or a spacer inside.

-The use of embeds permits flat mating surfaces, these can be sanded (for better flatness and fit). They also allow replacing natches if they get broken.

-A set of four interlocks (4 embeds, 4 clips, 2 spacers, 2 natches) weighs 8.7g.

Consider starting with a 0.1mm allowance (e.g. 4.8mm nipple inside a 4.9mm space). Print all four to check for fit. Then do cycles of adjusting the allowances and printing again until they fit.

v6 Beer Bottle Drawing

Fits standard swing top stoppers.

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

3D print this, pour in plaster to make a slip casting mold! My previous work on this project assumed a smaller 3D printer (making it necessary to print flanged PLA mold sections that clip together). But larger 3D printers are now common, making the CAD work much easier. This OnShape drawing is parametric for height, body diameter, wall and plaster thickness, and neck height (for the full bottle set body=160mm, neck=96). This uses my standard natch system. Neck vertices are proportional to height, so resizing works well. The top end is filleted to permit the longest possible mold on the print bed (diagonally). The bottom inside perimeter is chamfered, strengthening the default 0.8mm side wall junction to the base (that being said, be careful not to flex it too much when removing it from the print bed).

Doing this smaller size is for prototyping and testing. Casting plaster on a 3D print creates artifacts; these were not an issue. This PLA mold prints quickly, it has a hollow back side, permitting easy removal with a heat gun. There is no spare, it employs a pour spout, making the mold shorter and producing a better lip.

Need a stoneware slip casting recipe? L4768E or L4768H are a good choice. A glaze recipe? How about GA6-B (or similar)? Go full DIY with this, you will never turn back.

Videos

Links

| Projects |

Mold Natches

Natches are an interlocking mechanism using in plaster molds for ceramics. They enable quick and accurate registry when assembling multiple pieces of a mold. |

| Glossary |

Mold Natches

At digitalfire we are big fans of slip casting and want to help people and companies (even hobbyists) to integrate it into their production. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy