| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A giant cookie-cutter for slab built mugs

View and print it now using the Downloads page link

Available as a Product on the Downloads page

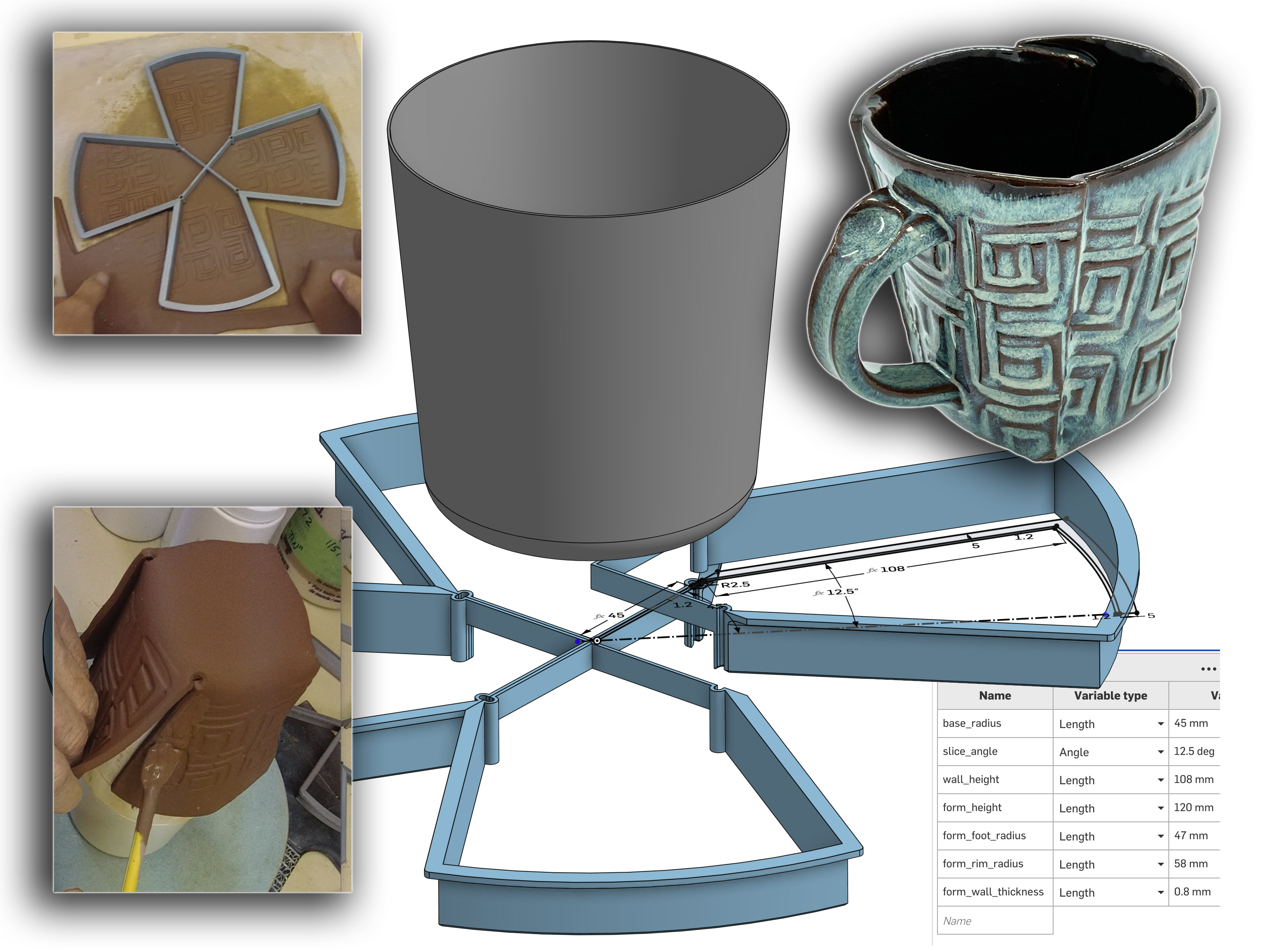

3D print four of these and glue them together to make a large cookie cutter for producing slab-built mugs. 3D print the cup, fill it with plaster and remove the PLA using a heat gun. Roll out a thin slab of clay, press the cutter into it using a round wooden batt, make sure it is not sticking to the board and flip it over onto the plaster form. Handles can even be attached while it is on the form. If clay is plastic it can be used quite stiff. Experiment, adjust sizing and dimensions and reprint to fine-tune.

This has been drawn "parametrically" with OnShape. I only had to draw half of one of the quarters (I mirrored that, extruded and then did a circular pattern of 4). The downloads page (link above) has a free link to view this drawing at OnShape.com. To 3D print, right-click the part (from the list on the lower left, "Quarter 1" and "Cup"). Choose the Export option and select 3MF as the file type (it should go to your downloads folder). Open it with your slicer and print (turn the quarter over and make four). You can even export in formats that other CAD software can open. Better yet, import it into your OnShape account to see the design history and change multiple aspects of the geometry in the variables panel (the drawing will adjust automatically). Other dimensions (e.g. cut depth) can be edited manually. Parametric design is revolutionary and it is now accessible even to hobbyists; it fits my try-it, adjust-it and try-it-again way of working.

Available as a Product on the Downloads page

Related Pictures

Large cookie-cutter 3D-printed in four pieces

This picture has its own page with more detail, click here to see it.

These four sections were glued together to make a larger one. The plastic wrap (top left) rounds the corners. This method makes it possible to quickly precision-cut the shape for making many pie-crust mugs at a time. Later, I reprinted these templates on a better 3D printer so the vertex holes (top right) cut larger and are better formed (these holes are important, they enable the folds to overlap naturally at the corners). For thin-walled pieces like this, it is necessary to use a highly plastic clay so that when the board is flipped, the four sides fall downward against the mold without ripping (I have a tissue under each to assure that none will stick to the board during flipping). The overlaps are simply glued with slip (no scoring is needed). As soon as possible, each piece is turned over to ensure even drying. These almost never crack no matter how fast they are dried. Incredibly thin-walled pieces can be made.

Videos

Links

| Projects |

Cookie Cutting clay with 3D printed cutters

We are finding more and more applications for this simple process of cookie-cutting shapes in ceramics. You won't believe whats possible and how easy it is to get started. |

| Projects |

Pie-Crust Mug-Making Method

Tony Hansen's project to make light, strong and functional slab-built mugs using tools and templates made possible by 3D design and 3D printing. |

| Glossary |

3D Design

3D Design software is used to create dimensionally accurate objects by sketching 2D geometry and transforming it using tools to rotate, extrude, sweep, etc. The software generates the polygon surface. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy