| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

OnShape CAD is Free for Hobby Makers:

Is it as good as Fusion 360?

It is very hard to let Fusion 360 CAD go. But the approaching $750 renewal is powerful motivation! OnShape is amazing. There is nothing to install, it runs in a browser tab like Google docs (see picture below). Sure, it won’t run offline, but I am almost never offline. It functions very similar to Fusion 360 for my basic requirements of making molds for slip casting. Recent experience with the complexity and slowness of Solidworks for Makers, which is total overkill for what I need, really makes OnShape look good.

My OnShape drawings are stored in my cloud account and are public. That sounded bad at first, but it also means that they are shareable with others (another person, whom I choose, can actually work on a drawing at the same time as me). The full OnShape is working in Firefox on my 2014 Mac Mini Ubuntu Linux machine. This is beyond exciting to me, traditional CAD has always required expensive hardware that is far beyond a hobbyist (of course, OnShape will also work in Safari on Mac and Chrome on Windows). A real bonus: I can edit drawings on iPad in what appears to be full power mode (although a mouse and keyboard are needed for serious work).

Besides the above, here are some of the features and advantages I am seeing:

-It opens and exports many professional CAD file types (a major drawback in SolidWorks for Makers).

-It is really fast, login is quick and a drawing can be open in seconds, this is way better than xDesign for Makers (from Solidworks).

-Documents are always saved, close one by simply clicking the home icon on the upper left.

-The timeline (called the "Feature Tree") can be reordered, turned back and has folders like Fusion 360.

-To 3D print just select part of your drawing, right-click and choose to export it in 3MF or STL format (it goes into the downloads folder).

-All tools are in one long, monochrome ribbon of tiny icons at the top but there is a tool searcher.

-Like Fusion 360, sketching constraints are inferred as sketches are created and applying them works in a similar fashion (but more aggressively). Their tiny symbols display in groups and associate to the point or line by a light grey line. Automatically applied constraints can make sketches behave in strange ways until you learn to find and remove the offending ones.

-Constraints and dimensions are movable so drawings can be uncluttered for printing.

-Section analysis is in the "Camera and Render Options" pop-up under the view cube.

-The spline and bezier sketching tools are not as interactive (a downside of running in a browser).

-It is not as good for making cookie cutters because it doesn’t do text nearly as well).

-Parameters, called variables, are more in your face; they are even shown in the timeline.

-Panning, rotating and the viewcube work a little differently. The iPad version of OnShape beats Fusion easily in this respect.

-OnShape does not appear to support text along a path like Fusion.

The secret weapon of learning OnShape: An AI chatbot. Just ask any question about how to do something. One helpful migration from Fusion 360 is to print the sketch(es) (with constraints and dimensions) and work from that to create the equivalent in OnShape. An advantage of OnShape is that if you get stuck (e.g. drawing goes red), you can share a link with a more knowledgeable friend to tell you what is wrong. Most often the issue is conflicting constrains.

Related Pictures

3D mechanical design software 2025:

Which is the best for mold making in ceramics?

This picture has its own page with more detail, click here to see it.

CAD software and 3D printing are a potential revolution in vessel mold-making for ceramics (3D modelling is another topic). But there are two big problems: There is no way a potter, hobbyist or even small manufacturer can afford the typical software cost. While it is true most have free or low-cost trial or hobby versions, the strings attached are deal breakers. The second problem is the complexity of learning - that can be a bigger obstacle than cost.

Until the recent price increase, Fusion 360 seemed to be exactly what was needed. A great way to on-board the CAD world, using the free version and its great learning resources and best-in-class user interface. It is new and modern, a YouTube star. It is fully parametric, supporting constraints and a timeline. True, it can choke on more complex drawings on consumer computers, but we don’t need to do those. But, for commercial use, it costs $700/yr. But that is cheap compared to some others! Upon discovery of the capability, the cost might be doable for you.

Here are the ones you likely cannot afford (and maybe don't want):

-OnShape runs in your browser and on iPad; in our testing, it looks really good. Free-version drawings are public (but no other restrictions). Going private costs $1500/yr.

-Rhino is usable for CAD but is polygonal and targeted at modelling. It is not fully parametric and does not have a traditional timeline (however, Rhino+Grasshopper is life-changing for geeks, both for CAD and modelling). $1000 to buy, but upgrading is $500+.

-Solidworks is a long-time proven product, it is fully parametric with editable history. Runs on Windows only (or the xDesign product runs in a browser like OnShape). It is low cost for hobby use (but the restriction of not being able to save or open the commercial SolidWorks file format is a potential deal-breaker for hobbyists). For commercial use: $2600/yr in 2025.

Some upcoming possibilities:

-FreeCAD is becoming more viable. It is parametric, has constraints and exports and imports popular formats (but with lots of issues). Its model tree is equivalent to the Fusion 360 timeline, but more clunky and depends on careful setting of constraints. The learning curve right now puts it out of reach of most. But a capital injection, like Blender got, is coming.

-Shapr 3D costs $299/yr, also works on iPad (which Fusion 360 does not), and uses the Parasolid engine like OnShape and SolidWorks. But it seems to be targeted at being intuitive for conceptual modelling and quick prototyping for drawings that are finalized in other products (limited support for accurate feature placement, constraints, parametrics and boolean operations).

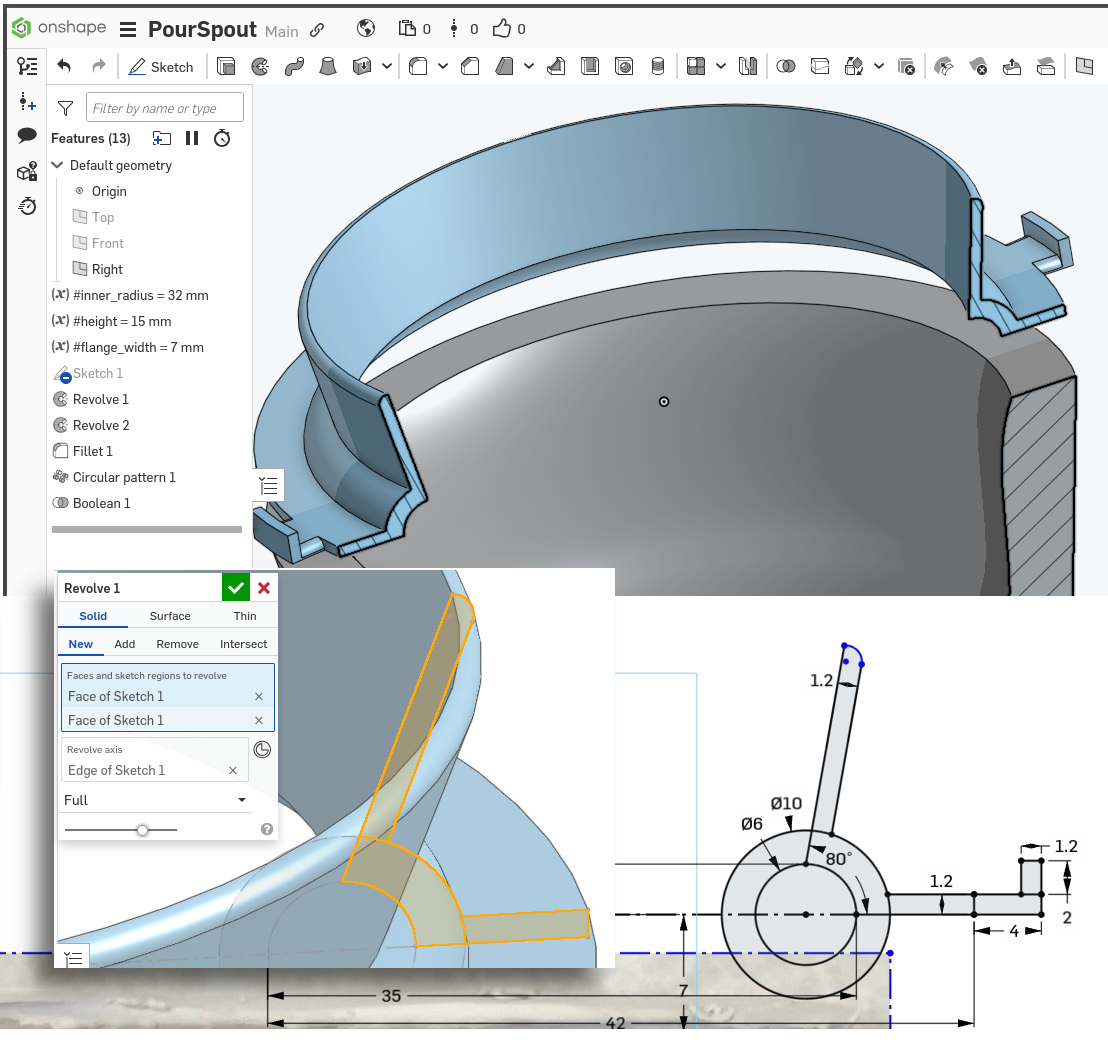

3D Printed Pour-spout Forms a Rounded Lip

First date with OnShape went great!

This picture has its own page with more detail, click here to see it.

This 3D-printed PLA pour spout potentially increases the utility of this one-piece plaster mold. As can be seen on the upper section analysis, the spout is designed to form the lip of this small Medalta Potteries bowl (and provide a guide for cutting its inside edge). It has lugs that extend outward to enable holding it down using rubber bands. I intend that it will be cleanly removable after the piece begins to pull away from the mold, leaving a high-quality lip that only needs a little trimming. This spout also permits precise monitoring of when to pour out the slip and it prevents most of the mess made using traditional molds having a spare.

This is the first piece I have made wholly using OnShape CAD. Experience with Fusion 360 gives me expectations of how this should work and those expectations are generally being met. Cost is no longer an obstacle to adopting professional 3D CAD for mold making. I am using OnShape on my 2014 Mac Mini running Ubuntu Linux (on 16gb RAM). And Prusa Slicer, OctoPrint, GIMP, Kdenlive, InkScape and productivity software are all running smoothly on it.

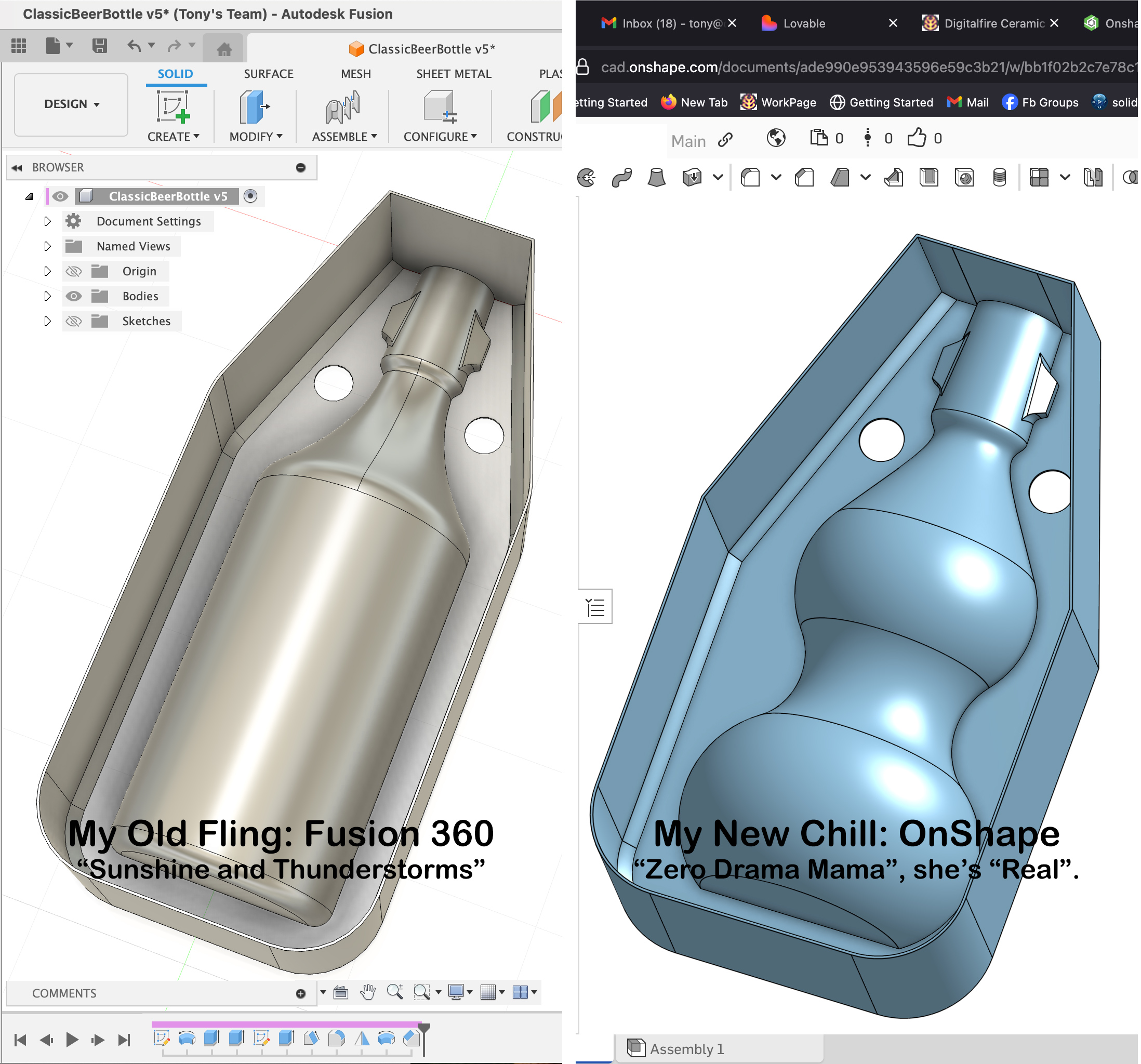

My Breakup with Fusion 360

I had a "Little Dictator", now I have a "Partner"

This picture has its own page with more detail, click here to see it.

I am just a simple guy, a hobby 3D printing "Maker", I focus on making molds for ceramic slip casting. I don't need a "high maintenance" CAD partner.

Fusion 360 and I were not a good match. It was her world, Windows and Mac only - I had to live in it. She was the “Queen of Complicated”, always on the drama channel of new features far beyond what I needed, rather than refining the simple ones I did need. And she was expensive to take out, costing way more than what I needed ($750/year).

OnShape is my new chill. She will go out, at full power, to Linux and iPad. She's a keeper. I don’t need a user manual for her. She's not a princess but a partner, social not a snob. I don't feel like I am on a roller coaster without a seatbelt, rather I am with someone that is easy to be around and way more powerful than she looks.

Videos

Links

| URLs |

https://www.onshape.com

OnShape parametric cloud-native CAD software This is looking like my new favorite 3D CAD package. It is free for hobby makers, runs in a browser so it works on almost any computer. And it works on iPad. If you have Fusion 360 experience you will hit the ground running, most of the tools and functionality needed for mold making are very similar. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy