| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

A plaster table: Better than a pugmill, essential for testing

This is an example of an angle iron utility table being made into a plaster table. The cardboard sides extend upward to make the slab thicker and create a buffer gap to prevent the expanding and setting plaster from pressing outward on the frame. 150 lbs plaster (92 lbs water) was poured into the plastic-lined space (the bottom cardboard sections were supported from below). In a dry enough climate, this table could make enough clay to support slurry-to-plastic production for a potter (a thicker slab and a fan would enable even more capacity). The slurry-up process is better than a pugmill for small operations. It's much cheaper and is an easier way to utilize scrap material and weigh out custom recipes. The clay quality and de-airing is better (without hard chunks and contamination common to pugmilling). The procedure generates much less dust and the tank is easily cleaned. Slurries are easily sieved, especially if you have a sieve shaker.

Related Pictures

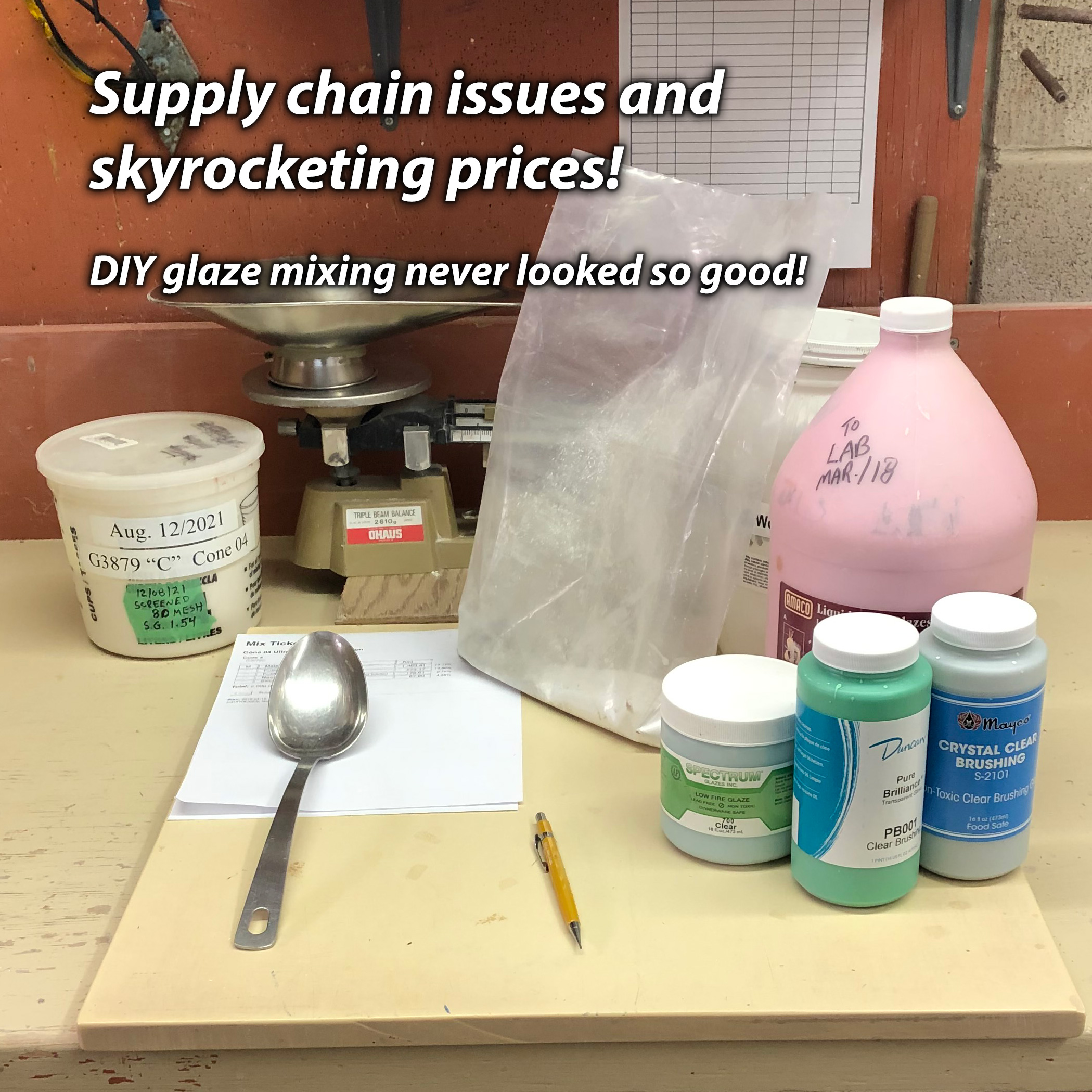

When Supply Chains Broke, Prices Soared.

We haven’t forgotten. Time for DIY!

This picture has its own page with more detail, click here to see it.

Material prices began skyrocketing during COVID. No one is affected more than prepared glaze manufacturers; they have complex supply chains that affect not only price but also availability and consistency of their products. Now might be the time for DIY, to start learning how to weigh out the ingredients to make at least some of your own, especially brushing glazes. You could be armed with good base recipes that fit your clay bodies, without crazing or shivering, by design, not by accident, as with commercial products. And you will be more resilient to supply issues. Add stains, opacifiers and variegators to the bases to make anything you want. Admittedly, ingredients in your recipes can also become unavailable! But DIY give you options. When you "understand" glaze ingredients and what each contributes to the recipe and oxide chemistry, you are equipped to go well beyond weathering material supply issues. You will improve recipes at the same time as adjusting them to accommodate alternative materials. It is not rocket science; it is just work accompanied by organized record-keeping and good labelling.

Videos

Links

| Glossary |

Native Clay

A clay that a potter finds, tests and learns to process and use himself. To reduce the costs of importing materials manufacturers, especially in Asia, often develop processes for clays mined in their locality. |

| Glossary |

Plaster table

Essential in a pottery studio for dewatering reclaim clay, stiffening clay that is too soft or making your own clay bodies. |

| Glossary |

Pugmill

The practice of removing air from clay as it is pugged. Deaired clay has better forming properties and produces a smoother fired surface. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy