| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Standard 3/8 inch Self-Interlocking Mold Natch

We can 3D print these and improve them

Available as a Product on the Downloads page

Once you try these you will never go back to the use of registration keys in traditional mold making. Unfortunately, these natches are not easy to get in North America. Or even online. But you can 3D print them yourself (we use PLA filament, but TPM would be a good option). This design interlocks with standard 3/8" natches used in industry. There are more aspects to printing and using these than meets the eye. Here are some things we noted (and changed):

-The base can be widened for sticking on the build plate better.

-Glue the build plate, on your 3D printer, to make sure these stick well.

-The inner edge is chamfered to ensure better insertion of the nipple.

-Print without infill for better strength.

-These are hollow, no print support is needed.

-The bottom can be widened to stick better to the build plate.

-The ribs can be moved.

-A 9.8 mm hole is needed in the mold.

Once we moved to the use of CAD and 3D printing of block and case molds, these were abandoned in fovor of a four-part system.

Available as a Product on the Downloads page

Related Pictures

v1 DIY Four-Part Mold Natch System

Essential for 3D mold-making in ceramics

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

Plastic natches are used in traditional mold making for slip-cast ceramics (instead of registration keys). They are cast into plaster molds to provide durable and good-fitting interlocks between pieces. They are self-interlocking, a popular size is the 3/8" or 9.5 mm (nipple diameter) natch. However, these have not proven suitable for the mold making process described on this site. The Digitalfire four-part system accommodates 3D printing (usually using PLA filament) case molds for pouring plaster, block molds for pouring rubber case molds and even hybrid solutions. Here are some features of our system:

-13.5mm holes in 3D printed case molds are all that is needed to adapt to these.

-3D printing case and block molds necessitate pouring plaster and rubber into shells with planar mating surfaces downward that must sit flat on the work table (traditional natches don’t work in this setting).

-Casting an embed into a mold enables gluing (or friction fitting) a natch or a spacer inside.

-The use of embeds permits flat mating surfaces, these can be sanded (for better flatness and fit). They also allow replacing natches if they get broken.

-A set of four interlocks (4 embeds, 4 clips, 2 spacers, 2 natches) weighs 8.7g.

Consider starting with a 0.1mm allowance (e.g. 4.8mm nipple inside a 4.9mm space). Print all four to check for fit. Then do cycles of adjusting the allowances and printing again until they fit.

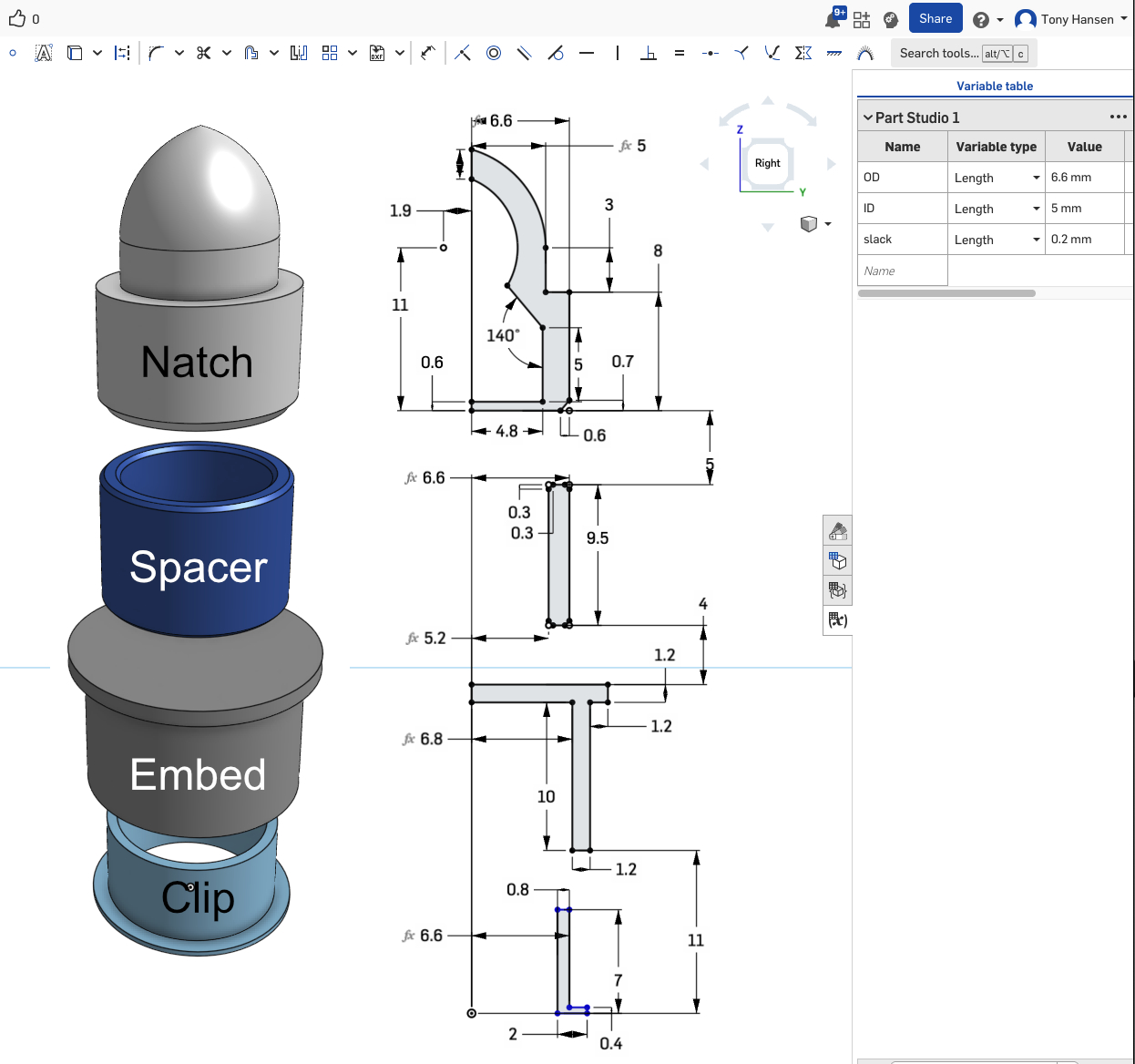

v2 Digitalfire Mold Natches in OnShape

These are even better than before

Available on the Downloads page

This picture has its own page with more detail, click here to see it.

Until now, I have done these in Fusion 360. But in OnShape and my new dimensioning method they are even better. If you are a hobby maker like me, then OnShape is free. This updated design only has three parameters: ID (inside diameter), OD (outside diameter), and slack (addition or subtraction for a good fit).

Print all four of these at the same time. Repeat cycles of adjusting the slack parameter and printing again until they fit into and over each other well (the better quality your printer to smaller the "slack" dimension can be). Print them in multiples of seven: Two natches, two embeds, two clips and one spacer (these are the proportions in which you will be consuming them).

An advantage of OnShape is that it enables sharing; the link is below. To 3D-print it select all four, right-click on one of them, export to 3MF format, open that file in your slicer software, position (and replicate/orient items), then print or export to a G-Code file.

Coming soon: Throw the teapot and slip-cast the handle and spout

This picture has its own page with more detail, click here to see it.

How would you like to be able to create a parametric CAD model of a teapot lid? Then 3D print a case mold and pour a multi-piece plaster working mold? Imagine easily making multiple-size one-off molds to accommodate any teapot you throw!

This is perfect for M370 or Polar Ice (both have throwing and casting versions). Or, how would you like to be able to formulate a casting slip having the same appearance and degree of maturity as the throwing body you use? More information coming soon (based on the L4807 casting body).

Next, imagine casting the handles, rims and spouts also. Information on how to draw and print them also coming soon.

Videos

Links

| Typecodes |

Fusion 360 Drawings

These are available for download. Fusion 360 is our chosen 3D solid modelling software as of 2021. To produce these files we export them in F3D format. |

| Glossary |

Mold Natches

At digitalfire we are big fans of slip casting and want to help people and companies (even hobbyists) to integrate it into their production. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy