| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

An unevenly cooled tile has cracked

Example of a severely dunted cone 6 stoneware tile. This problem was deliberately created by stacking several tiles on top of this one. This set up a temperature gradient across it so that different parts passed through quartz inversion at different times.

Related Pictures

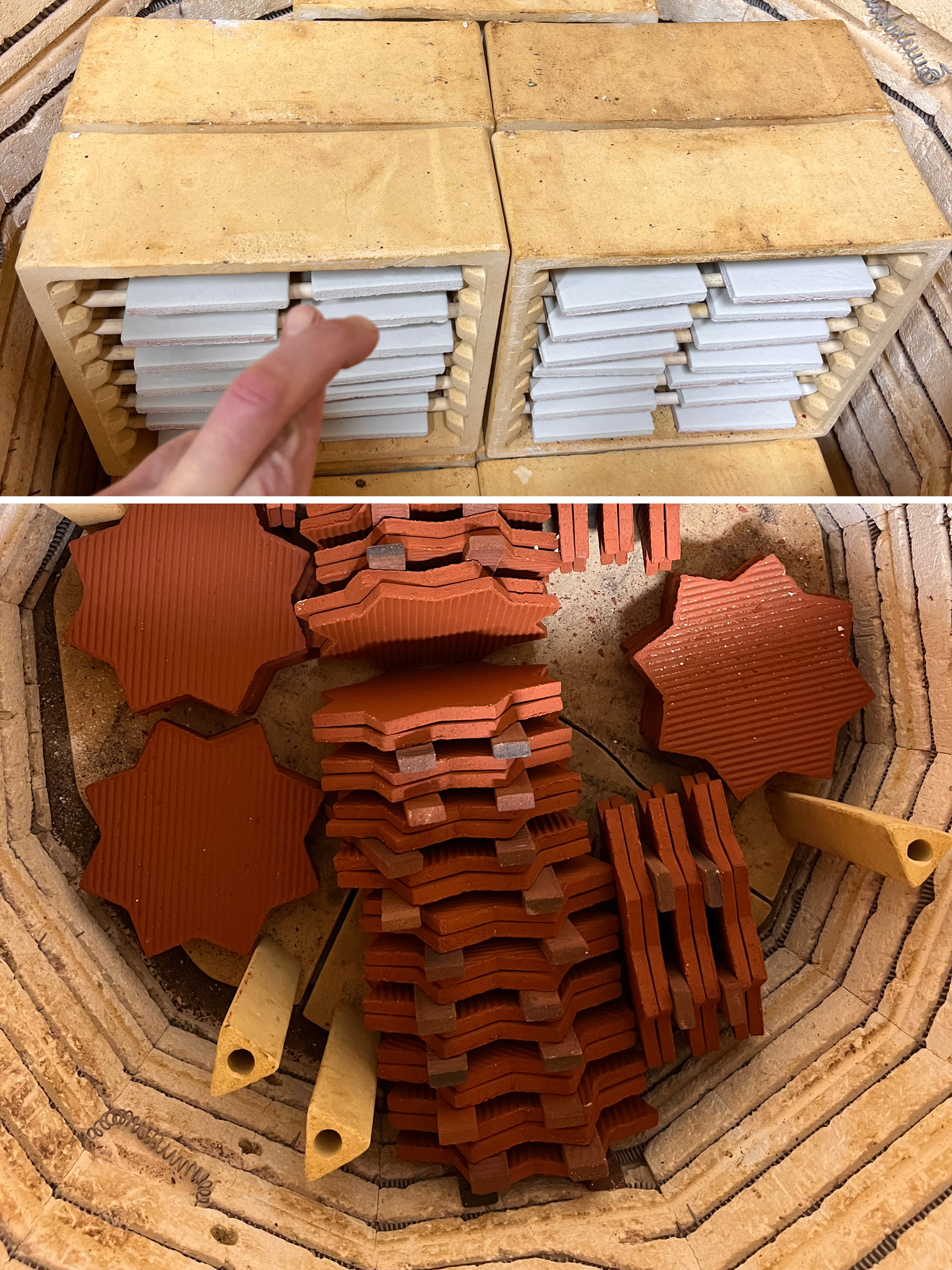

Tile stacking in an electric kiln - Fingers crossed!

This picture has its own page with more detail, click here to see it.

Small-scale operations everywhere are making tile like this. Most use plastic clay intended for pottery, this introduces more drying shrinkage complicating drying them flat. Stacking them in the kiln can be a game of chance. Stacked too tightly and they crack (mostly because of quartz inversion). Stacked to loosely and most of the energy goes into heating the shelves and stackers. Using a clay with minimum large quartz particles is the best way to avoid dunting, however that is also a balance since such clays are more difficult to fit glazes to (without crazing).

Videos

Links

| Glossary |

Dunting

Dunting generally refers to firing cracks that occur in ceramic ware as it is cooled in the kiln. The reason is generally uneven cross section or too rapid cooling. |

| Glossary |

Quartz Inversion

In ceramics, this refers to the sudden volume change in crystalline quartz particles experience as they pass up and down a temperature window centering on 573C. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy