| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Polish the plaster surface, not the 3D-printed shell-mold

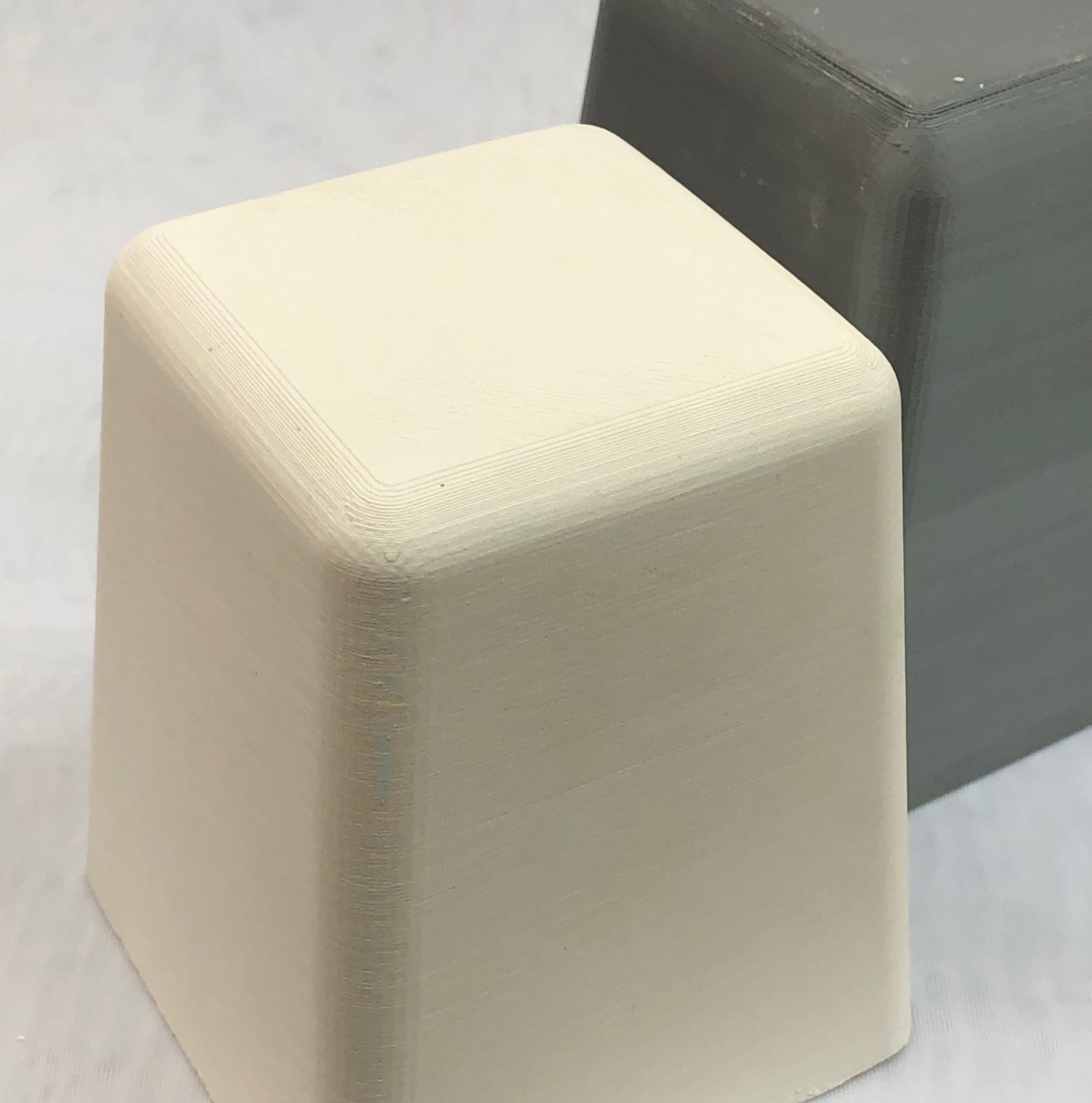

This plaster model was just removed from the 3D-printed shell behind. It dropped out easily (after tapping it at-an-angle on the corners), this worked well despite the resolution lines on the surface. While I could have spent time sanding and smoothing the inside of the shell-mold, it is actually far easier to smooth the surface of the plaster form after extraction. Seconds with a metal rib completely smooths any of the surfaces. And remember, it is easier to remove plaster items cast inside of 3D-printed molds rather than cast around the outside of them. I named this size as 95-5-113, referring to the TopWith-Angle-Height. I set these as parameters in Fusion 360 and can print adjustments to this size (labelling them appropriately).

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy