| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

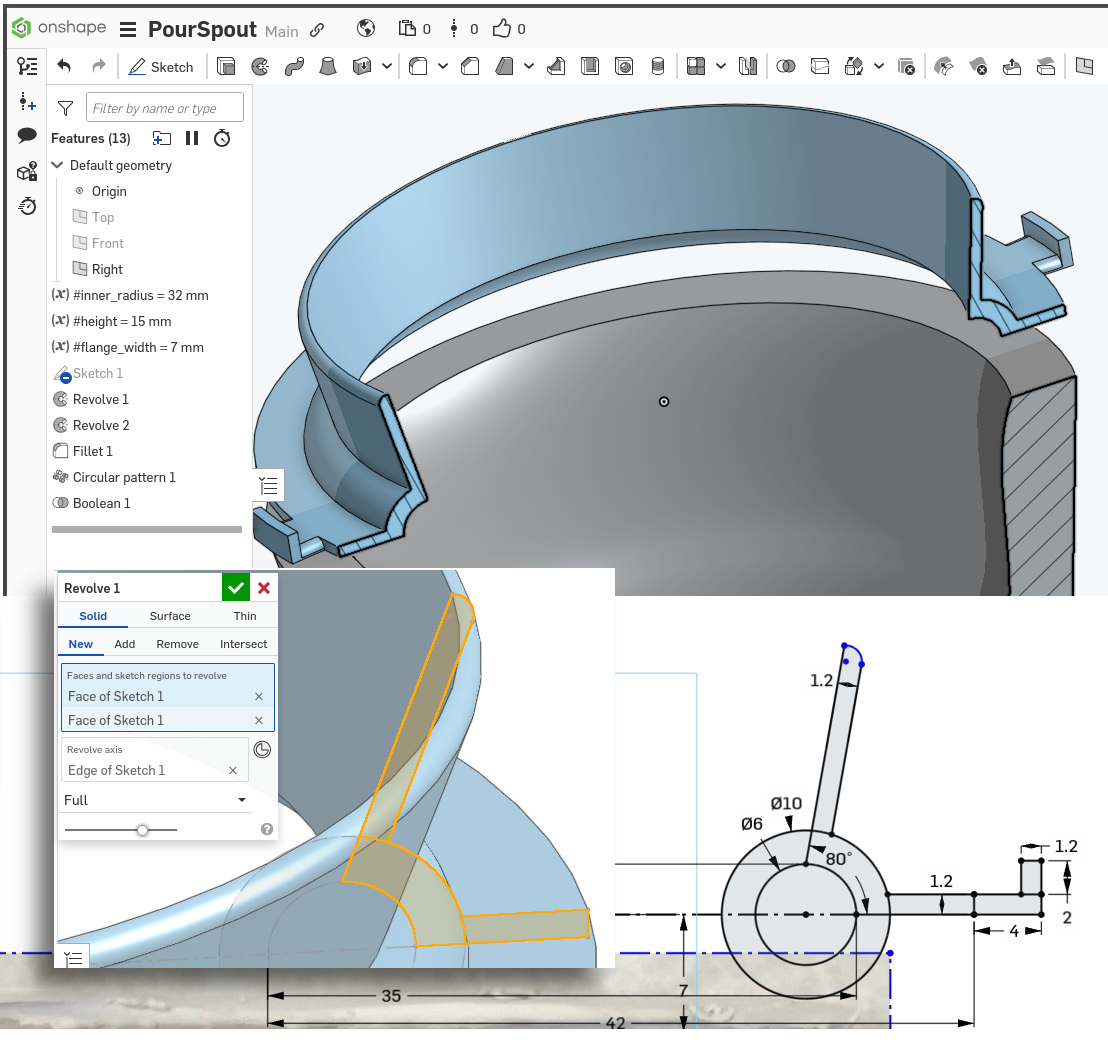

3D Printed Pour-spout Forms a Rounded Lip

First date with OnShape went great!

This 3D-printed PLA pour spout potentially increases the utility of this one-piece plaster mold. As can be seen on the upper section analysis, the spout is designed to form the lip of this small Medalta Potteries bowl (and provide a guide for cutting its inside edge). It has lugs that extend outward to enable holding it down using rubber bands. I intend that it will be cleanly removable after the piece begins to pull away from the mold, leaving a high-quality lip that only needs a little trimming. This spout also permits precise monitoring of when to pour out the slip and it prevents most of the mess made using traditional molds having a spare.

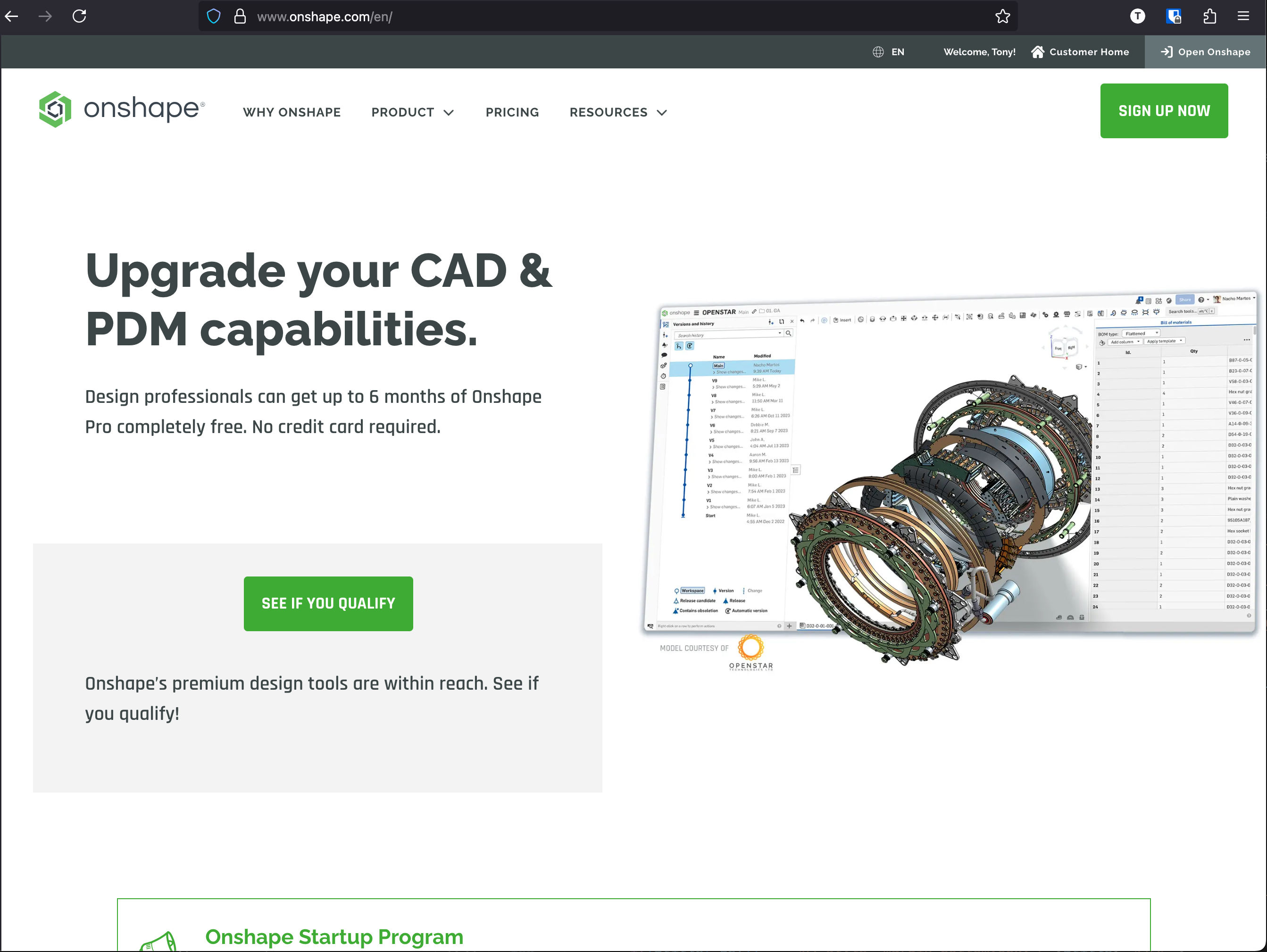

This is the first piece I have made wholly using OnShape CAD. Experience with Fusion 360 gives me expectations of how this should work and those expectations are generally being met. Cost is no longer an obstacle to adopting professional 3D CAD for mold making. I am using OnShape on my 2014 Mac Mini running Ubuntu Linux (on 16gb RAM). And Prusa Slicer, OctoPrint, GIMP, Kdenlive, InkScape and productivity software are all running smoothly on it.

Related Pictures

OnShape CAD is Free for Hobby Makers:

Is it as good as Fusion 360?

This picture has its own page with more detail, click here to see it.

It is very hard to let Fusion 360 CAD go. But the approaching $750 renewal is powerful motivation! OnShape is amazing. There is nothing to install, it runs in a browser tab like Google docs (see picture below). Sure, it won’t run offline, but I am almost never offline. It functions very similar to Fusion 360 for my basic requirements of making molds for slip casting. Recent experience with the complexity and slowness of Solidworks for Makers, which is total overkill for what I need, really makes OnShape look good.

My OnShape drawings are stored in my cloud account and are public. That sounded bad at first, but it also means that they are shareable with others (another person, whom I choose, can actually work on a drawing at the same time as me). The full OnShape is working in Firefox on my 2014 Mac Mini Ubuntu Linux machine. This is beyond exciting to me, traditional CAD has always required expensive hardware that is far beyond a hobbyist (of course, OnShape will also work in Safari on Mac and Chrome on Windows). A real bonus: I can edit drawings on iPad in what appears to be full power mode (although a mouse and keyboard are needed for serious work).

Besides the above, here are some of the features and advantages I am seeing:

-It opens and exports many professional CAD file types (a major drawback in SolidWorks for Makers).

-It is really fast, login is quick and a drawing can be open in seconds, this is way better than xDesign for Makers (from Solidworks).

-Documents are always saved, close one by simply clicking the home icon on the upper left.

-The timeline (called the "Feature Tree") can be reordered, turned back and has folders like Fusion 360.

-To 3D print just select part of your drawing, right-click and choose to export it in 3MF or STL format (it goes into the downloads folder).

-All tools are in one long, monochrome ribbon of tiny icons at the top but there is a tool searcher.

-Like Fusion 360, sketching constraints are inferred as sketches are created and applying them works in a similar fashion (but more aggressively). Their tiny symbols display in groups and associate to the point or line by a light grey line. Automatically applied constraints can make sketches behave in strange ways until you learn to find and remove the offending ones.

-Constraints and dimensions are movable so drawings can be uncluttered for printing.

-Section analysis is in the "Camera and Render Options" pop-up under the view cube.

-The spline and bezier sketching tools are not as interactive (a downside of running in a browser).

-It is not as good for making cookie cutters because it doesn’t do text nearly as well).

-Parameters, called variables, are more in your face; they are even shown in the timeline.

-Panning, rotating and the viewcube work a little differently. The iPad version of OnShape beats Fusion easily in this respect.

-OnShape does not appear to support text along a path like Fusion.

The secret weapon of learning OnShape: An AI chatbot. Just ask any question about how to do something. One helpful migration from Fusion 360 is to print the sketch(es) (with constraints and dimensions) and work from that to create the equivalent in OnShape. An advantage of OnShape is that if you get stuck (e.g. drawing goes red), you can share a link with a more knowledgeable friend to tell you what is wrong. Most often the issue is conflicting constrains.

Quick fix to make these spareless molds more usable

This picture has its own page with more detail, click here to see it.

These legacy slip casting molds from Medalta Potteries (made from 80 year old masters). They are difficult and time-consuming to use and produce less than optimal results because they have no top section (this no spare) and require constant filling during cast time. Demolding requires cutting the lip flat (top right). But a lot of time trimming and sponging is needed to round it again, but making the lip even and symmetric is difficult to say the least.

I found a way to make these molds easier to use and better: A 3D printed spare/pouring spout that also defines a rounded rim. It can be glued to the top of the mold with slip. Of course, the PLA print is not absorbent, but this still works because the mold top edge is able to dewater the slip even inside the contoured top it forms. The print also acts as a cutting guide to cleanly cut anway any clay inside the spout section, leaving a clean line inside the lip. And the shrinkage of the clay pulls the pitcher lip away from the print.

Videos

|

Same Beer Bottle Mold Using Fusion 360 and OnShape CAD

I will make a classic Medalta beer bottle case-mold for 3D printing using OnShape CAD (just pour in plaster and you have a mold to slip cast bottles). I will highlight the differences between OnShape and Fusion 360 as we go. |

Links

| URLs |

https://www.onshape.com

OnShape parametric cloud-native CAD software This is looking like my new favorite 3D CAD package. It is free for hobby makers, runs in a browser so it works on almost any computer. And it works on iPad. If you have Fusion 360 experience you will hit the ground running, most of the tools and functionality needed for mold making are very similar. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy