| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Frit Melt Fluidity Comparison - 1800F

Fired at 350F/hr to 1800F and held for 15 minutes (I already did firings from 1300F-1750F in 50 degree increments, all of them are visible in the parent project). Frit 3110, 3134, 3195, F75 have run all the way down. All of the frits have softened and melted slowly over a range of temperatures (hundreds of degrees). By contrast, Gerstley Borate, the only raw material here, suddenly melted and flowed right over the cliff (between 1600 and1650)! But not before Frit 3602 and FZ16 had done so earlier. Frit 3249 is just starting to soften but F69 (the Fusion Frits equivalent) is a little ahead of it. LA300 and Frit 3124 are starting also. F524, F38, F15 will all be over the end by the next firing. The melt surface tension is evident by the way in which the melts spread out or hold together.

Related Pictures

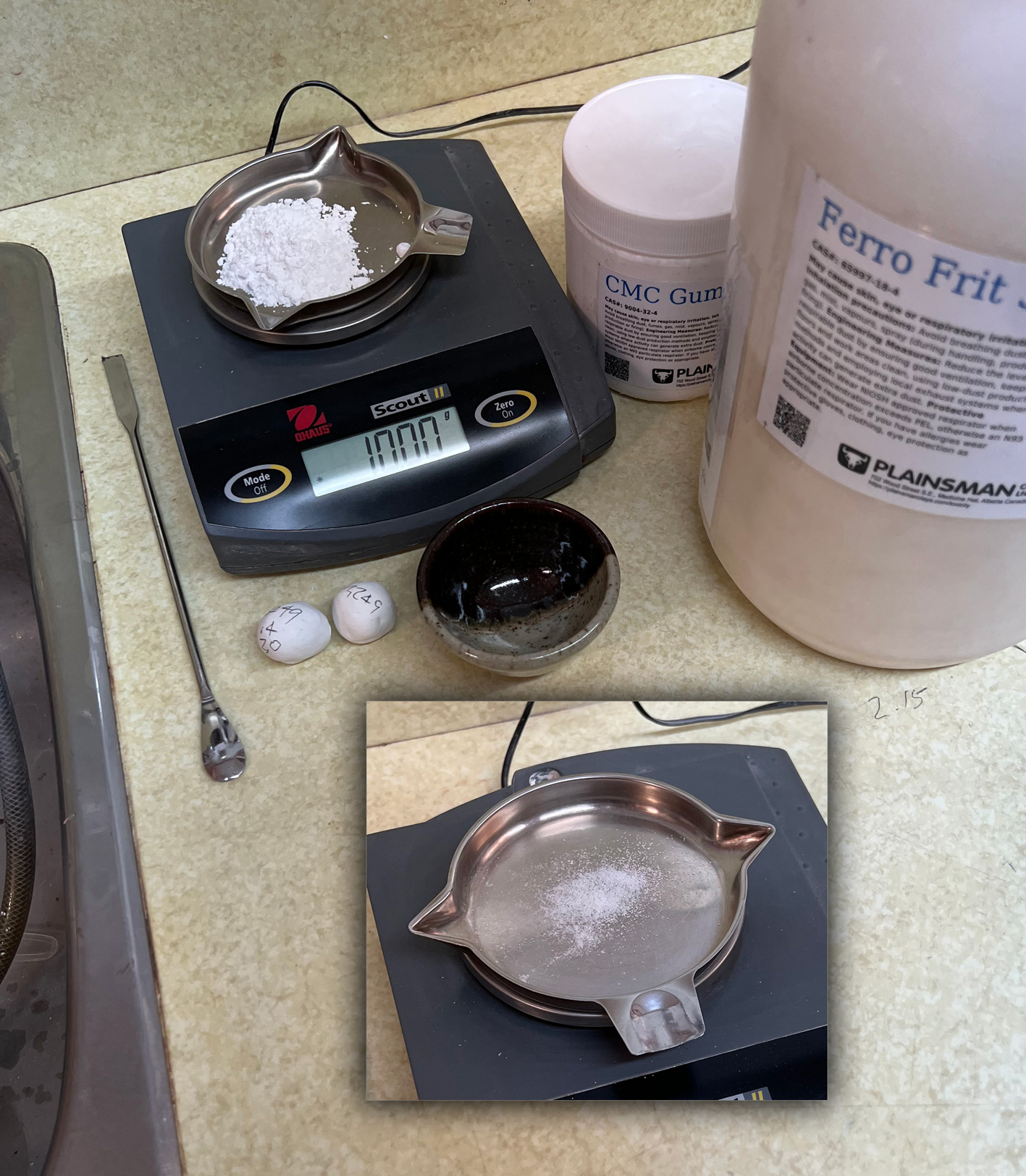

Preparing balls for a melt fluidity test using CMC gum

This picture has its own page with more detail, click here to see it.

We use 11g of the material being tested, e.g. a frit, (the right amount for one ball), 0.11g CMC (1%). Of course, you need a 0.01g scale to be able to accurately weigh 0.1g (that is a really small amount). Put them in a small ziplock bag, zip it to entrap air and roll the zipper down to inflate it. Shake well to mix. Stir the powder into water (~5-8g) in a small bowl. Pour it onto a plaster slab - it dewaters very quickly (e.g. as little as 10 seconds) - just as the water sheen is gone, peel it up with a rubber rib. Smear it back down and peel it up every few seconds until it is plastic and formable (but not sticky). For better formability use 1.5% CMC gum - however, the ball will dry slower - drying time is an issue with this method, you will need a heat lamp or other drier of some sort (e.g. a dehydrator). You will also need a plaster surface to absorb the excess water (which invariably happens).

Videos

Links

| Materials |

Ferro Frit 3110

High sodium, high thermal expansion low boron frit. A super-feldspar in clay bodies. Melts a very low temperatures. |

| Materials |

Ferro Frit 3124

A commonly available calcium borosilicate frit. |

| Materials |

Ferro Frit 3134

A frit with 23% B2O3. The most common of frits used in pottery in North America. Around the world, other companies make frits of equivalent chemistry. |

| Materials |

Ferro Frit 3195

A commonly used boron frit, it is a balanced glaze all along at cone 06-02 (with the addition of 10-15% kaolin). Not fully glossy. |

| Materials |

Ferro Frit 3249

A magnesia borosilicate frit. Very low thermal expansion and melting point. Invaluable in pottery to increase the MgO in glazes and thereby prevent crazing. |

| Materials |

Frit LA-300

|

| Materials |

Frit B325

|

| Materials |

Ferro Frit 3602

|

| Materials |

Fusion Frit F-15

|

| Materials |

Fusion Frit F-38

High strontium low alumina borosilicate flux. |

| Materials |

Fusion Frit F-69

A magnesia borosilicate frit having very low thermal expansion and melting point. Commonly used as a substitute for Ferro frit 3249. |

| Materials |

Fusion Frit F-75

High sodium, high thermal expansion low boron frit. An equivalent of Ferro Frit 3110. |

| Materials |

Fusion Frit FZ-16

The champion in our frit melt-off competitition. This frit showcases the amazing fluxing power of boron and zinc working together. It is 15.5% ZnO. |

| Materials |

Fusion Frit F-524

A low fire base glaze, add 10% kaolin, adjust thermal expansion using other frits. |

| Temperatures | Comparison of frit melts at 1800F (982-) |

| Glossary |

Frit

Frits are used in ceramic glazes for a wide range of reasons. They are man-made glass powders of controlled chemistry with many advantages over raw materials. |

| Glossary |

Melt Fluidity

Ceramic glazes melt and flow according to their chemistry, particle size and mineralogy. Observing and measuring the nature and amount of flow is important in understanding them. |

| Projects |

Comparing the Melt Fluidity of 16 Frits

|

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy