| Monthly Tech-Tip | No tracking! No ads! |

ZnO (Zinc Oxide)

Data

| Co-efficient of Linear Expansion | 0.094 |

|---|---|

| Frit Softening Point | 1800C (From The Oxide Handbook) |

Notes

-Together with PbO it is considered one of the metallic oxide fluxes. In small amounts, zinc helps in the development of glossy and brilliant surfaces the way lead did. ZnO has a high refractive index.

-ZnO starts its fluxing action around 1000C (i.e. bristol glazes) whereas by itself ZnO is very refractory, not melting until 1975C. It is a late and vigorous melter for low fire glazes and thus useful in fast fire applications.

-ZnO is easily changed to Zn metal by the action of CO and H2 in the reduction phase of a gas-fired kiln (and possibly poorly ventilated electric kilns). Pure Zn metal melts at 419C and then boils and vaporizes at 907C.

-It does take time for zinc to volatilize, and meanwhile, it encourages the melting process to begin earlier in stoneware applications, making it more vigorous. However, zinc metal in a more molten glaze is also more reducible.

-ZnO is a low expansion secondary flux which is handy to prevent crazing if used for, or instead of, high expansion fluxes. It improves elasticity so that glazes that might otherwise craze or shiver will fit.

-ZnO can extend firing range.

-In moderate to high amounts, it acts to produce mattes and crystalline surfaces, especially if supersaturated (up to 0.8 molar) and cooled slowly (produces crystal phases like Zn2SiO4, that is, willemite). However, these crystalline surfaces can be rough enough to cause cutlery marking.

-Zinc can improve durability in some glazes. In others, it can reduce resistance to acid attack.

-At low temperatures, small amounts can have a marked effect on gloss and melting, although at temperatures below Orton cone 03-02 it is not normally an active flux.

-At middle temperatures, zinc can be used as a major flux in amounts to 5%.

-At higher oxidation temperatures, it is valuable to provide a smooth transition from sintered to melted stage. Zinc is common in fast-fire glazes.

-In certain mixtures, it is very powerful, even in small amounts. The melting power per unit added drops quickly as the amount used exceeds 5%.

-If used with boron ZnO is considered to also have amphoteric qualities. More surprisingly, in the glass industry, ZnO:SiO2, mixed 50:50 molar, produces a zinc silicate optical glass (albeit well beyond typical temperatures in traditional ceramics, e.g. 1600C). Many types of glasses can be produced from this as a starting point by introducing minor amounts of Na2O, Li2O, K2O and BaO at the expense of ZnO.

-Zinc has a complicated color response. It can have harmful and helpful effects on blues, browns, greens, pinks and is not recommended with copper, iron, or chrome. Recommended for nickel greens.

Yikes. Cutlery marking this bad on a popular glaze!

This picture has its own page with more detail, click here to see it.

An example of how a spoon can cutlery mark a glaze. This is a popular middle temperature recipe used by potters. The mechanism of its matteness is a high percentage of zinc oxide that creates a well-melted glaze that fosters the growth of a mesh of surface micro-crystals. However these crystals create tiny angular protrusions that abrade metal, leaving a mark. Notice the other matte flow on the left (G2934), it not only has a better surface (more silky feel) but also melts much less (its mechanism is high MgO in a boron fluxed base). It is does not cutlery mark at all!

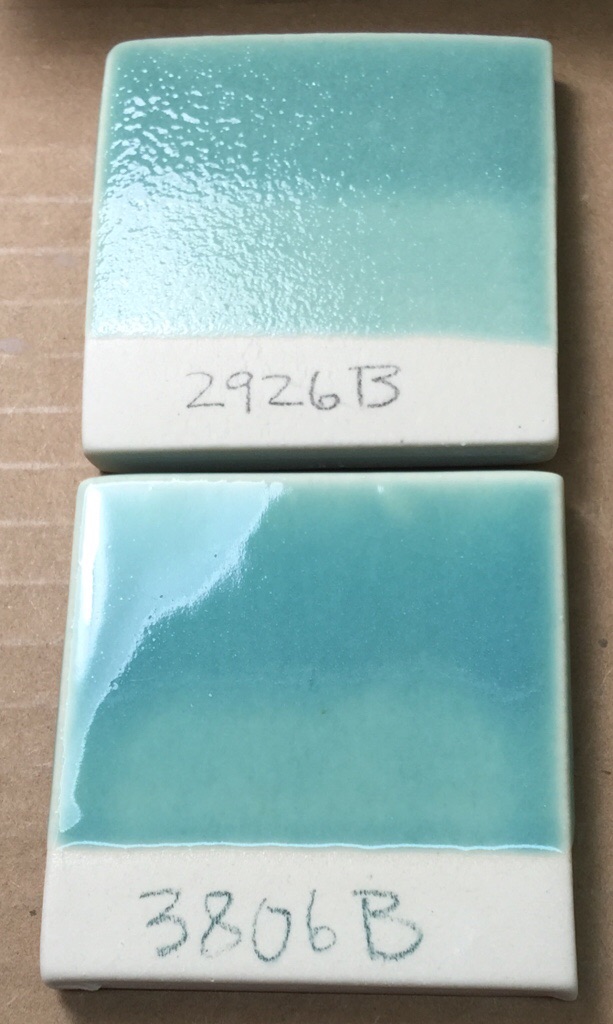

Raw and calcined zinc oxides in a crystalline glaze

This picture has its own page with more detail, click here to see it.

Zinc oxide calcined (left) and raw (right) in typical crystalline glaze base (G2902B has 25% zinc) on typical cone 6 white stoneware body. This has been normally cooled to prevent crystal development. The melting pattern is identical. Note how badly these are crazed, this is common since crystalline glazes are normally high in sodium.

A good matte glaze. A bad matte glaze.

This picture has its own page with more detail, click here to see it.

A melt fluidity comparison between two cone 6 matte glazes. G2934 is an MgO saturated boron fluxed glaze that melts to the right degree, forms a good glass, has a low thermal expansion, resists leaching and does not cutlery mark. G2000 is a much-trafficked cone 6 recipe, it is fluxed by zinc to produce a surface mesh of micro-crystals that not only mattes but also opacifies the glaze. But it forms a poor glass, runs too much, cutlery marks badly, stains easily, crazes and is likely not food safe! The G2934 recipe is google-searchable and a good demonstration of how the high-MgO matte mechanism (from talc) creates a silky surface at cone 6 oxidation the same as it does at cone 10 reduction (from dolomite). However it does need a tin or zircon addition to be white.

Two stains. 4 colors. Will the guilty oxide please step forward.

This picture has its own page with more detail, click here to see it.

These pairs are G2934 matte and G2916F glossy cone 6 base glaze recipes. The left pair has 5% maroon stain added, the right pair 5% purple stain. Why? The Mason Colorworks reference guide has the same precaution for both stains: the host glaze must be zincless and have 6.7-8.4% CaO (this is a little unclear, it is actually expressing a minimum, the more the CaO the better). The matte recipe calculates to 11% CaO, the glossy to 9%. So there is enough CaO. The problem is MgO (it is the mechanism of the matteness in the left two), it impedes the development of both colors (although not mentioned on the Mason docs).

Ceramic Oxide Periodic Table

Pretty well all common traditional ceramic base glazes are made from less than a dozen elements (plus oxygen). Go to the full picture of this table and click or tap each of the oxides to learn more (on its page at digitalfire.com). When materials melt, they decompose, sourcing these elements in oxide form. The kiln builds the glaze from them, it does not care what material sources what oxide (assuming, of course, that all materials do melt or dissolve completely into the melt to release those oxides). Each of these oxides contributes specific properties to the glass. So, you can look at a formula and make a good prediction of the properties of the fired glaze. And know what specific oxide to increase or decrease to move a property in a given direction (e.g. melting behavior, hardness, durability, thermal expansion, color, gloss, crystallization). And know about how they interact (affecting each other). This is powerful. A lot of ceramic materials are available, hundreds - that is complicated when individual materials source multiple oxides. Viewing a glaze as a simple unity formula of ceramic oxides is just simpler.

An ultra-clear brilliantly-glossy cone 6 clear base glaze? Yes!

This picture has its own page with more detail, click here to see it.

I am comparing 6 well known cone 6 fluid melt base glazes and have found some surprising things. The top row are 10 gram GBMF test balls of each melted down onto a tile to demonstrate melt fluidity and bubble populations. Second, third, fourth rows show them on porcelain, buff, brown stonewares. The first column is a typical cone 6 boron-fluxed clear. The others add strontium, lithium and zinc or super-size the boron. They have more glassy smooth surfaces, less bubbles and would should give brilliant colors and reactive visual effects. The cost? They settle, crack, dust, gel, run during firing, craze or risk leaching. Out of this work came the G3806E and G3806F.

Why fast fire glazes employ zinc - a melt fluidity test tells us

This picture has its own page with more detail, click here to see it.

We are comparing the degree of melt fluidity (10 gram GBMF test balls melted down onto a tile) between two base clear glazes fired to cone 6 (top) and cone 1 (bottom).

Left: G2926B clear boron-fluxed (0.33 molar) clear base glaze sold by Plainsman Clays.

Right: G3814 zinc-fluxed (0.19 molar) clear base.

Two things are clear: Zinc is a powerful flux (it only takes 5% in the recipe to yield the 0.19 molar). Zinc melts late: Notice that the boron-fluxed glaze is already flowing well at cone 1, whereas the zinc one has not even started. This is very good for fast fire because the unmelted glaze will pass more gases of decomposition from the body before it melts, producing fewer glaze defects.

In pursuit of a reactive cone 6 base that I can live with

This picture has its own page with more detail, click here to see it.

These GLFL tests and GBMF tests for melt-flow compare 6 unconventionally fluxed glazes with a traditional cone 6 moderately boron fluxed (+soda/calcia/magnesia) base (far left Plainsman G2926B). The objective is to achieve higher melt fluidity for a more brilliant surface and for more reactive response with colorant and variegator additions (with awareness of downsides of this). Classified by most active fluxes they are:

G3814 - Moderate zinc, no boron

G2938 - High-soda+lithia+strontium

G3808 - High boron+soda (Gerstley Borate based)

G3808A - 3808 chemistry sourced from frits

G3813 - Boron+zinc+lithia

G3806B - Soda+zinc+strontium+boron (mixed oxide effect)

This series of tests was done to choose a recipe, that while more fluid, will have a minimum of the problems associated with such (e.g. crazing, blistering, low run volatility, susceptibility to leaching). As a final step the recipe will be adjusted as needed. We eventually evolved the G3806B, after many iterations settled on G3806E or G3806F as best for now.

2% Copper carbonate in two different cone 6 copper-blues

This picture has its own page with more detail, click here to see it.

The top base glaze has just enough melt fluidity to produce a brilliant transparent (without colorant additions). However it does not have enough fluidity to pass the bubbles and heal over from the decomposition of this added copper carbonate! Why is lower glaze passing the bubbles? How can it melt better yet have 65% less boron? How can it not be crazing when the COE calculates to 7.7 (vs. 6.4)? First, it has 40% less Al2O3 and SiO2 (which normally stiffen the melt). Second, it has higher flux content that is more diversified (it adds two new ones: SrO, ZnO). That zinc is a key to why it is melting so well and why it starts melting later (enabling unimpeded gas escape until then). It also benefits from the mixed-oxide-effect, the diversity itself improves the melt. And the crazing? The ZnO obviously pushes the COE down disproportionately to its percentage.

One way for an ultra clear at low fire: Magnesia-alkali, low Si:Al ratio, more boron.

This picture has its own page with more detail, click here to see it.

On the left is G2931J, a zinc alkali fluxed and high Si:Al ratio glaze. Those look like micro-bubbles but they are much more likely to be micro-crystals (high-zinc and high-silica is the mechanism for crystalline glazes). G2931K on the right has much more boron, double the Al2O3, less SiO2 and is magnesia-alkali instead of zinc-alkali. It is the product of dozens of tests to find an ultra-clear having a glassy smooth surface. This particular chemistry, although having only a 6:1 SiO2:Al2O3 ratio is ultra-gloss. In addition, is has low expansion, will fast fire and the boron is not high enough to compromise the hardness.

Links

| Articles |

Unwanted Crystallization in a Cone 6 Glaze

Someone is having a problem with a cone 6 glaze going glossy and crystallizing, this article rationalizes the problem in terms of chemistry |

| Materials |

Zinc Oxide

A pure source of ZnO for ceramic glazes, it is 100% pure with no LOI. |

| Materials |

Frit

Frits are made by melting mixes of raw materials, quenching the melt in water, grinding the pebbles into a powder. Frits have chemistries raw materials cannot. |

| Glossary |

Crystalline glazes

A type of ceramic glaze made by potters. Giant multicolored crystals grown on a super gloss low alumina glaze by controlling multiple holds and soaks during cooling |

| Glossary |

Limit Formula

A way of establishing guideline for each oxide in the chemistry for different ceramic glaze types. Understanding the roles of each oxide and the limits of this approach are a key to effectively using these guidelines. |

| Glossary |

Flux

Fluxes are the reason we can fire clay bodies and glazes in common kilns, they make glazes melt and bodies vitrify at lower temperatures. |

| URLs |

http://en.wikipedia.org/wiki/Zinc_chromate

Zinc Chromate at Wikipedia |

| URLs |

https://www.researchgate.net/publication/255795602_Properties_of_Zinc_Silicate_Glasses_and_Melts

Properties of Zinc Silicate Glasses and Melts Research paper about technical and optical glasses and glass ceramics based on ZnO:SiO2 zinc silicate as a starting point. |

| Hazards |

Zinc Compounds Toxicology

|

Mechanisms

| Glaze Color | Zinc reacts with chromium to form the very stable crystalline compound zinc chromate (ZnCr2O4). |

|---|---|

| Glaze Crystallization | Almost all crystalline glazes are high in ZnO, its presence coupled with low alumina and adequate SiO2 is the secret. The very fluid melt created is perfect for growing a wide range of metallic zinc-silicate crystals. |

| Glaze Opacifier | In larger amounts ZnO can produce opacity or whiteness in glazes. It exhibits refractory properties and can contribute to the development of a crystal mesh surface. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy