| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Rheology

In ceramics, this term refers to the flow and gel properties of a glaze or body suspension (made from water and mineral powders, with possible additives, deflocculants, modifiers).

Key phrases linking here: rheological, rheology - Learn more

Details

Rheology refers to the array of characteristics that a ceramic slurry exhibits: its density, flow, thixotropy, permeability, viscosity, stability, etc. Technicians seek to understand and control the dynamics of the slurries they use (to maintain consistency and optimize them for the product and process at hand). Their task is complicated by variations in water consistency and quality, materials changes, temperature variations, growth of mold and mixing procedure inconsistencies. In a factory setting a casting slurry, for example, is typically maintained to perform well if its fluidity, one-minute thixotropy and density all fall within certain ranges.

For example, when it is desirable to have low water content in slurries, deflocculation is employed. Flocculants can be used for higher water concentration, sedimentation prevention or to create thixotropic characteristics. At time both are used, to both reduce water content and gel a slurry.

The Old Hickory clay website has some excellent papers on understanding rheology in production of ceramic ware.

Related Information

Fundamentals of Fluid Mechanics - book

This picture has its own page with more detail, click here to see it.

Many aspects of ceramic production relate to the control of fluids (mostly suspensions). This is also true of material production. If you want to solve problems and optimize your process this is invaluable knowledge. This book is available at amazon.com.

A casting slip of 1.9 specific gravity. Should we use it?

This picture has its own page with more detail, click here to see it.

A hydrometer is being used to check the specific gravity of a ceramic casting slip in a graduated cylinder. Common traditional clay-containing ceramic slips are usually maintained around 1.75-1.8. In this case the slurry was too heavy, almost 1.9. Yet it is very fluid, why is this? It has both too much clay and too much deflocculant. While it is possible to use such a slip, it will not drain as well and it will gel too quickly as it stands. It is better to settle for a lower specific gravity (where you can control the thixotropy and it is easier to use). It might have been better to simply fill a 100cc cylinder and weigh it to get the specific gravity (slurries that are very viscous do not permit hydrometers to float freely).

Confirming slip viscosity using a paint-measuring device

This picture has its own page with more detail, click here to see it.

A Ford Cup is being using to measure the viscosity of a casting slip. These are available at paint supply stores. This is a #4 (4.25mm opening), it holds 100ml and drains water in 10 seconds. This casting slip has a specific gravity of 1.79. Having made it many times, our experience indicates 40-seconds as a drain target (after high energy mixing). In production situations, the seconds-value this test produces enables an audit-trail for quality control and problem solving. When first mixing a slurry, under-deflocculating and eye-balling the viscosity is typical, during that period the slurry gels while draining and Ford cup measurements are not valid. When the mixing process has been perfected and viscosity stabilized the Ford Cup becomes practical.

Don’t overthink this type of measurement or the type of cup or opening size (you can even make your own cup). You must still determine the optimal flow rate based on experience with your process. This technique is more about maintaining to ongoing adherence to a standard you define.

Slip having proper rheology is so much better

This picture has its own page with more detail, click here to see it.

This deflocculated slurry of 1.79 specific gravity (only 28% water) has just been poured into a mold. The mold is dry, the wall thickness of the bowl will build quickly and the liquid level will sink only slightly. It can be drained in minutes (for a wall thickness of 3-4 mm). The clay is not too plastic (too fine particle sized) so it is permeable enough to enable efficient water migration to the plastic face. If the specific gravity of this slip was too low (too high a percentage of water) the liquid level would sink drastically during the time in the mold, take longer to build up a wall thickness and water-log the mold quickly. If the slip contained too much deflocculant it would cast slower, settle out, form a skin and drain poorly. If it had too little deflocculant it would gel in the mold and be difficult to pour out. The rheology is just right.

Carefully measure specific gravity using a scale and graduated cylinder

This picture has its own page with more detail, click here to see it.

This is a convenient way to measure the specific gravity of a glaze or clay slurry fairly accurately. Get a graduated cylinder like this (e.g. Amazon.com). Be careful with cheap plastic ones, check them with water and mark the true 100cc mark if needed. Counterbalance the empty graduated cylinder to zero on your 0.01g scale. Fill it to the 100 mark. The specific gravity is the weight divided by 100.

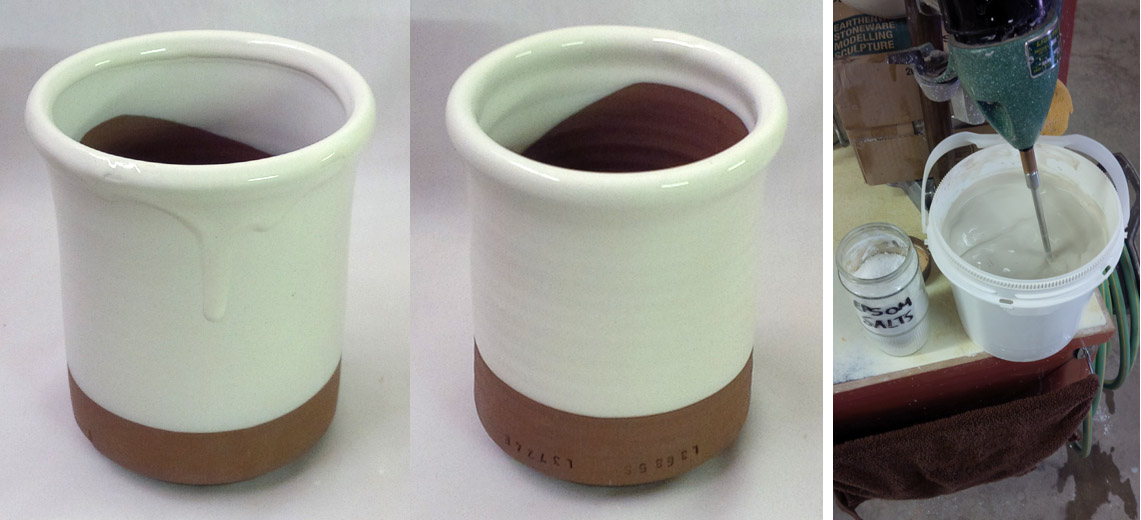

Adding water actually made this white engobe run less? How?

This picture has its own page with more detail, click here to see it.

The white slip (applied to a leather hard cup) on the left is dripping downward from the rim (even though it was held upside down for a couple of minutes!). Yet that slurry was very viscous with a 1.48 specific gravity. Why? Because it was not thixotropic. The fix? I watered it down to 1.46 (making it runny) and added pinches of powdered epsom salts (while mixing vigorously) until it thickened enough to stop motion in about 1-2 seconds on mixer shut-off. But that stop-motion is followed by a bounce-back. That is the thixotropy. It is easy overdo the epsom salts (gelling it too much), I add a drop or two of Darvan to rethin it if needed. When the engobe is right it gels after about 10 seconds of sitting, so I can stir it, dip and extract the mug, shake to drain it and then it gels and holds in place. Keep in mind, this is a pottery project. In industry they deflocculate engobes to reduce water content. But a deflocculated slurry can still be gelled (if it is runny).

Clay, feldspar, wollastonite, silica and frits are insoluble. Right?

This picture has its own page with more detail, click here to see it.

Wrong! That is what the glaze was made of that was in this bucket. The scum on the inside is so hard that it is extremely difficult to remove, even using a scraper or a scrubber. Even lime-a-way does not remove it all. This is an example of how water-soluble materials can be. When this glaze settles out the water on top is brown (like this scum) yet all the material powders are white! So it is not surprising that glaze viscosity changes over time and things dissolve and impact rheology.

Inbound Photo Links

Control gel using Veegum, brushing properties with CMC gum |

Bad and good glaze application: The difference was the rheology. |

Links

| Glossary |

Thixotropy

Thixotropy is a property of ceramic slurries of high water content. Thixotropic suspensions flow when moving but gel after sitting (for a few moments more depending on application). This phenomenon is helpful in getting even, drip-free glaze coverage. |

| Glossary |

Deflocculation

Deflocculation is the magic behind the ceramic casting process, it enables slurries having impossibly low water contents and ware having amazingly low drying shrinkage |

| Glossary |

Flocculation

The flocculation process enables technicians in ceramics to create an engobe or glaze slurry that gels and goes on to ware in a thick yet even, non-dripping layer. |

| Glossary |

Slip Casting

A method of forming ceramics. A deflocculated (low water content) slurry is poured into absorbent plaster molds. As it sits in the mold, usually 10+ minutes, a layer builds against the mold walls. When thick enough the mold is drained. |

| Glossary |

Water in Ceramics

Water is the most important ceramic material, it is present every body, glaze or engobe and either the enabler or a participant in almost every ceramic process and phenomena. |

| Glossary |

Once fire glazing

Refers to the practice of firing ceramics in one firing (rather than two) to produce a fully glazed product. This practice requires more technical expertise. |

| Glossary |

Bisque

Potters and some manufacturers fire ceramic ware twice, once to prepare it for glazing (call bisquit firing) and the second time to melt the glaze onto it. |

| Glossary |

Specific gravity

In ceramics, the specific gravity of slurries tells us their water-to-solids ratio. That ratio is a key indicator of performance and enabler of consistency. |

| Glossary |

Slurry Processing

|

| Materials |

Garamite

|

| Materials |

Claytone

|

| Materials |

Vinegar

|

| Projects |

Minerals

|

| Projects |

Properties

|

| URLs |

http://www.rheology.org

Society of Rheology Website |

| URLs |

http://www.malvern.co.uk/labeng/products/iwtm/rheological_properties.htm

Malvern Instruments Rheology page |

| URLs |

http://www.oldhickoryclay.com

Old Hickory website |

| URLs |

https://www.smac.it/en/dettaglio.php?idprod=239

K-Flow automatic glaze flow rate controller for spray nozzles The system will display the instantaneous flow of each individual nozzle and signal any anomalies by alarm or stop the production line or the application device to avoid glaze and material waste. |

| URLs |

https://www.smac.it/en/dettaglio.php?idprod=210

D-Glaze automatic glaze density controller Maintains the glaze slurry density in existing glaze production lines. |

| URLs |

https://www.smac.it/en/dettaglio.php?idprod=226

V-Check glaze slurry viscosity monitoring device Monitors the viscosity of the glaze delivered by the tank pump and signals by alarm values exceeding the tolerance range set by the operator. |

| Articles |

Where do I start in understanding glazes?

Break your addiction to online recipes that don't work or bottled expensive glazes that you could DIY. Learn why glazes fire as they do. Why each material is used. How to create perfect dipping and brushing properties. Even some chemistry. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy