| Monthly Tech-Tip | No tracking! No ads! | |

How to choose ceramic materials to source needed oxides

How does one choose which material to source each oxide needed when doing glaze chemistry formula-to-batch? It is easy to overthink this. Insight-live has thousands of materials of which you likely only have a few. By tapping any of the oxide names in the calculation in a recipe panel it becomes evident quickly that it is fairly simple to know which material to source each oxide from. When ZnO is needed it is sourced by zinc oxide, SiO2 by silica, TiO2 by titanium dioxide, Li2O by lithium carbonate or spodumene, MgO by talc or dolomite, CaO by whiting or wollastonite, Al2O3 by kaolin or ball clay, KNaO by feldspar. The tricky one is B2O3, you’ll get that from frits available to you. The frit you use will bring many of the other oxides so their main sources (the other materials just listed) will need adjustment. This being said, the above must be tempered by material cost and by how the solid state and physical properties of materials affect slurry rheology, glaze laydown and drying.

Related Pictures

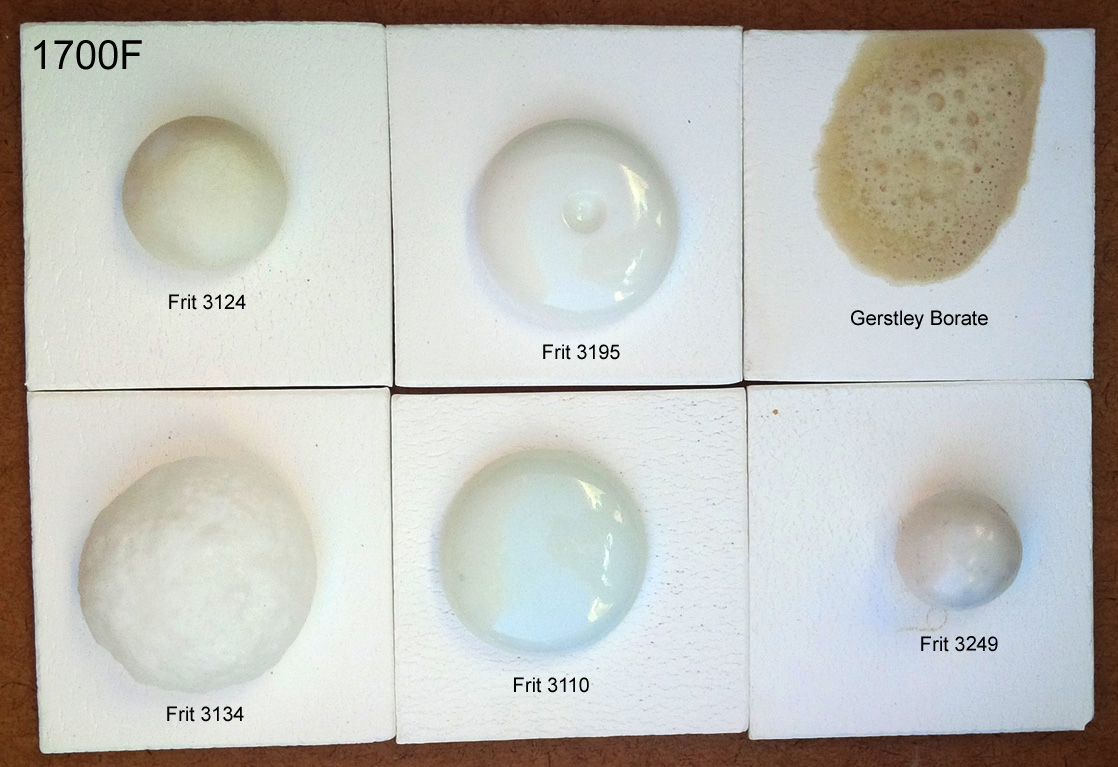

These common Ferro frits have distinct uses in traditional ceramics

This picture has its own page with more detail, click here to see it.

I used Veegum to form 10 gram GBMF test balls and fired them at cone 08 (1700F). Frits melt really well, they do have an LOI like raw materials. These contain boron (B2O3), it is a low expansion super-melter that raw materials don’t have. Frit 3124 (glossy) and 3195 (silky matte) are balanced-chemistry bases (just add 10-15% kaolin for a cone 04 glaze, or more silica+kaolin to go higher). Consider Frit 3110 a man-made low-Al2O3 super feldspar. Its high-sodium makes it high thermal expansion. It works really well in bodies and is great to make glazes that craze. The high-MgO Frit 3249 (made for the abrasives industry) has a very-low expansion, it is great for fixing crazing glazes. Frit 3134 is similar to 3124 but without Al2O3. Use it where the glaze does not need more Al2O3 (e.g. already has enough clay). It is no accident that these are used by potters in North America, they complement each other well (equivalents are made around the world by others). The Gerstley Borate is a natural source of boron (with issues frits do not have).

Step-by-step to do a formula-to-batch in Insight-Live.com

This picture has its own page with more detail, click here to see it.

Insight-live does not automate formula-to-batch calculations, but it does assist in doing them. And it provides the tools to create an audit trail of test results, pictures and notes and a path to document subsequent adjustments. Along the way, you gain material knowledge and intuition. In this example, we derive the recipe of materials needed to source the oxide formula of a zinc clear cone 6 glaze (sourcing the oxides needed using a Ferro frit and other common raw materials). We'll create the target in a panel, start the batch in a panel beside it, supply the B2O3 from a frit and then the fluxes from feldspar, zinc and whiting. Then finish by rounding out the Al2O3 and SiO2 from kaolin and silica. The picture below shows the panels, the original target formula on the left and the final derived recipe on the right. The derived transparent glaze is on the inside of the mug and the outside is G3875, another zinc clear with iron and chrome added to produce the orange.

Videos

Links

| Glossary |

Glaze Chemistry

Glaze chemistry is the study of how the oxide chemistry of glazes relate to the way they fire. It accounts for color, surface, hardness, texture, melting temperature, thermal expansion, etc. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy