| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Zinc Oxide

Alternate Names: ZnO, Zincite, Zinc 99

Description: Pure Source Of Zinc

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| ZnO | 100.00% | 1.00 | |

| Oxide Weight | 81.40 | ||

| Formula Weight | 81.40 | ||

Notes

Zinc oxide is a fluffy white to yellow-white powder having a very fine physical particle size (99.9% should pass a 325 mesh screen). It is made using one of two processes that produce different densities. The French process vaporizes and oxidizes zinc metal, the American process smelts a coal/zinc sulfide mix and oxidizes the zinc fumes.

Ceramic grades are often calcined to remove any physical water (so they do not clump in the bag). But these grades also have a larger particle size and lower surface area (e.g. 3 square meters per gram vs. less than 1; however 99.9% still passes 325 mesh). While calcined grades are said to produce fewer glaze surface defect problems, many ceramists have used the raw grades without serious issues. You can calcine (or re-calcine) zinc on your own in a bisque kiln at around 815C. However there are issues: First, because the calcined zinc wants to rehydrate (and get lumpy in the process) you must store it in an airtight container (some people calcine a mix of zinc and kaolin to prevent this, but theoretically such a mix should not even need to be calcined). Second, the calcined zinc may produce slurry thickening issues over time. Many zinc-bearing frits are available (e.g. Fusion FZ-16 has 15% ZnO) and incorporating one of them to source it instead of raw zinc oxide will produce glazes that are more fusible, have better clarity and fewer defects (a classic job for glaze chemistry calculations).

A lot of zinc is used in crystalline glazes (typically 25%), because these have no clay content, they bring out the best and worst of both the calcined and raw materials. The raw zinc suspends glazes better (the calcined settles out significantly more). The raw zinc takes more water, but since the glaze can thin out over time it is better to add less than needed at mixing time and mix thoroughly. The raw zinc screens better (although it can be a challenge to get either slurry through an 80 mesh screen).

Zinc oxide is soluble in strong alkalies and acids.

It can be an active flux in smaller amounts. While boron dominates as the key flux in middle temperature glazes, for example, zinc is employed in some base glazes to augment the B2O3 or even replace it entirely. No combination of the common raw materials feldspar, kaolin, silica, feldspar, calcium carbonate, dolomite and talc will melt properly at cone 6, however, a 5% addition of zinc can transform the mix into a glossy glaze. 5% more and it will be a very fluid glossy glaze. The zinc can also significantly reduce the thermal expansion of the glaze it is fluxing.

Zinc generally promotes crystalline effects and matteness/softness in greater amounts. If too much is used the glaze surface can become dry and the heavily crystalline surface can present problems with cutlery marking. Other surface defects like pitting, pinholing, blistering and crawling can also occur (because its fine particle size contributes to glaze shrinkage during drying and it pulls the glaze together during fusion).

Zinc oxide is thermally stable on its own to high temperatures, however, in glazes it readily dissolves and acts as a flux. Zinc oxide sublimes at 1800C but it reduces to Zn metal in reduction firing and then boils at around 900C (either causing glaze defects or volatilizing into the atmosphere; note that electric kilns with poor ventilation can have local reduction). While it might seem that zinc would not be useful in reduction glazes, when zincless and zinc-containing glazes are compared it is often clear that there is an effect (e.g. earlier melting, more crystallization and variegation). Thus some zinc has either remained or it has acted as a catalyst.

The use of zinc in standard glazes is limited by its price, its hostility to the development of certain colors and its tendency to make glazes more leachable in acids (although zinc itself is not considered a hazardous substance).

Zinc oxide is used in glass, frits, enamels and ferrites. Zinc oxide is also used in large quantities in the rubber and paint industries; in insulated wire, lubricants, and advanced ceramics.

Zinc Oxide is amount the purest powdered materials available (its actual chemistry closely matches the theoretical). As an example of how consistent this product is, Zochem sent out a letter in 2022 about a lead (Pb) spec change from 0.0024% to

0.0030%. Given the purity of manufactured products we have quoted a chemistry of 100% ZnO.

Related Information

Why fast fire glazes employ zinc - a melt fluidity test tells us

This picture has its own page with more detail, click here to see it.

We are comparing the degree of melt fluidity (10 gram GBMF test balls melted down onto a tile) between two base clear glazes fired to cone 6 (top) and cone 1 (bottom).

Left: G2926B clear boron-fluxed (0.33 molar) clear base glaze sold by Plainsman Clays.

Right: G3814 zinc-fluxed (0.19 molar) clear base.

Two things are clear: Zinc is a powerful flux (it only takes 5% in the recipe to yield the 0.19 molar). Zinc melts late: Notice that the boron-fluxed glaze is already flowing well at cone 1, whereas the zinc one has not even started. This is very good for fast fire because the unmelted glaze will pass more gases of decomposition from the body before it melts, producing fewer glaze defects.

Growing incredible glaze crystals is also about the chemistry

This picture has its own page with more detail, click here to see it.

Closeup of a crystalline glaze. Crystals of this type can grow very large (centimeters) in size. These grow because the chemistry of the glaze and the firing have been tuned to encourage them. This involves melts that are highly fluid (lots of fluxes) with added metal oxides and a catalyst. Typically, the fluxes are dominated by K2O and Na2O (from frits) and the catalyst is zinc oxide (enough to contribute a lot of ZnO). Because Al2O3 stiffens glaze melts, preventing crystal growth, it can be almost zero in these glazes (clays and feldspars supply Al2O3, so these glazes have almost none or either of them). The firing cycles involve rapid descents, holds and slow cools (sometimes with rises between them). Each discontinuity in the cooling curve creates specific effects in the crystal growth. These kinds of glazes are within the reach of almost anyone today since electronic controller-equipped kilns are now commodity items - one can fiddle with the chemistry and manage the testing of glazes in their insight-live.com account. But be ready for work, others on this path have done hundreds of firings to perfect a recipe and scedule.

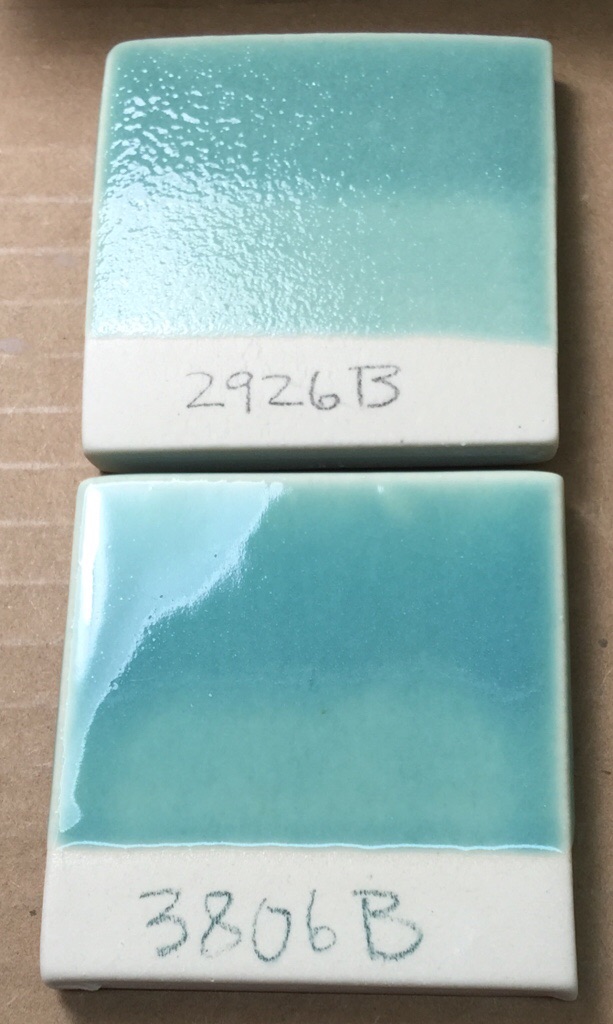

2% Copper carbonate in two different cone 6 copper-blues

This picture has its own page with more detail, click here to see it.

The top base glaze has just enough melt fluidity to produce a brilliant transparent (without colorant additions). However it does not have enough fluidity to pass the bubbles and heal over from the decomposition of this added copper carbonate! Why is lower glaze passing the bubbles? How can it melt better yet have 65% less boron? How can it not be crazing when the COE calculates to 7.7 (vs. 6.4)? First, it has 40% less Al2O3 and SiO2 (which normally stiffen the melt). Second, it has higher flux content that is more diversified (it adds two new ones: SrO, ZnO). That zinc is a key to why it is melting so well and why it starts melting later (enabling unimpeded gas escape until then). It also benefits from the mixed-oxide-effect, the diversity itself improves the melt. And the crazing? The ZnO obviously pushes the COE down disproportionately to its percentage.

Original container bag of zinc oxide

This picture has its own page with more detail, click here to see it.

Back side of original container of Zochem Zinc Oxide

This picture has its own page with more detail, click here to see it.

Frits instead of raw zinc, lithium, barium, strontium

This picture has its own page with more detail, click here to see it.

Raw material sources of zinc, lithium, barium, strontium have issues (e.g. precipitates in glaze slurries, toxicity, high drying shrinkage and carbon burnoff that affect laydown and fired surface defects like pinholes, blisters, orange peeling, crystallization). Yet the oxides that these materials supply to the glaze melt - ZnO, Li2O, BaO and SrO, can be sourced from frits which melt much better and remove most of the problems. Consider examples made by Fusion:

-Frit F-493 has 11% Li2O

-F-403 has 35% BaO

-F-581 has 39% SrO

-FZ-16 has 15% ZnO

These frits source other oxides but such are common in most glazes and glaze calculation can be used to retain the overall chemistry. Although these are expensive, the benefits are game changers. But there is a problem: Potters can't get these. Therefore they have difficulty creating the dazzling visual effects of many commercial glazes.

Links

| URLs |

http://en.wikipedia.org/wiki/Zinc_oxide

Zinc Oxide at Wikipedia |

| Hazards |

Zinc Compounds Toxicology

|

| Materials |

Zinc Carbonate

|

| Materials |

Zinc Oxide Raw

|

| Materials |

Zochem Grade 500 Zinc Oxide

|

| Typecodes |

Generic Material

Generic materials are those with no brand name. Normally they are theoretical, the chemistry portrays what a specimen would be if it had no contamination. Generic materials are helpful in educational situations where students need to study material theory (later they graduate to dealing with real world materials). They are also helpful where the chemistry of an actual material is not known. Often the accuracy of calculations is sufficient using generic materials. |

| Typecodes |

Flux Source

Materials that source Na2O, K2O, Li2O, CaO, MgO and other fluxes but are not feldspars or frits. Remember that materials can be flux sources but also perform many other roles. For example, talc is a flux in high temperature glazes, but a matting agent in low temperatures ones. It can also be a flux, a filler and an expansion increaser in bodies. |

| Temperatures | Zinc oxide boils and volatilizes (850-950) |

| Oxides | ZnO - Zinc Oxide |

| Glossary |

Matte Glaze

Random material mixes that melt well overwhelmingly want to be glossy, creating a matte glaze that is also functional is not an easy task. |

| Glossary |

Crystalline glazes

A type of ceramic glaze made by potters. Giant multicolored crystals grown on a super gloss low alumina glaze by controlling multiple holds and soaks during cooling |

| Glossary |

Metal Oxides

Metal oxide powders are used in ceramics to produce color. But a life time is not enough to study the complexities of their use and potential in glazes, engobes, bodies and enamels. |

| Minerals |

Sphalerite

The main ore of zinc. |

Data

| Density (Specific Gravity) | 5.6 |

|---|

Mechanisms

| Glaze Opacifier | Zinc oxide will produce opacity or whiteness, especially at low temperatures, if the calcium content is low. It does not opacify as well in boron glazes. It works well in combination with tin. |

|---|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy