| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Melting Temperature

The melting temperature of ceramic glazes is a product of many complex factors. The manner of melting can be a slow softening or a sudden liquifying.

Key phrases linking here: melting temperature - Learn more

Details

Unlike crystalline minerals, glazes do not have a specific melting temperature, they soften over a range of temperatures (the purity of a substance can be assessed by the sharpness of the melting point, glazes are mixes and therefore very impure). And after they have been melted they become increasingly fluid and homogeneous. The softening process is not a linear one, this is especially so because raw glaze powders are a mix of many different mineral (and possibly man-made) particles, each of which has its own melting behavior. Flux particles melt first but not just because they are fluxes. The mere proximity of other particles with which they like to interact creates a union that melts readily at temperatures much lower than either individual one would melt on its own. These interactions are also greatly enhanced when the particles are smaller and when groups of different particles react together (the more different types and sizes there are the more complex is their interactions). And then, as viscous glass melts evolve, they develop their own changing dynamics that can accelerate or slow the dissolution of remaining larger and more refractory unmelted ones. When sufficient time is available, the entire mass is melted. However as the last particle dissolves the melt exists as a discontinuity of chemistries and viscosities (phases). As yet more time passes the homogeneity of the mix increases. The higher the proportion of fritted materials the more predictable the process is.

That means that an individual glaze can actually serve well across a range of temperatures and can exhibit itself in a variety of ways. At one temperature it might be a matte, at another a glossy, at another a crystalline or reactive. Various firing schedules within a temperature will increase the number of personalities even more. It is thus better to see glazes as more dynamic and less easily pigeon-holed and classified.

Again, the complexities of oxide interactions and firing methods along with the wide range of physical and mineralogical properties of materials supplying oxides make the prediction of absolute values for fired properties an inexact and highly system-specific science. Modelling this in an absolute or precise sense (predicting exact viscosities at exact temperatures for any mix of materials) using chemistry and mathematics is thus not possible. Notwithstanding that, the single biggest factor affecting the degree to which we can predict what a melt will do (in a comparative way) is its chemistry. This is especially so when all other factors are kept equal. For example, if we can measure the melt fluidity at a specific temperature then we can predict whether it will melt more or less if specific changes are made to the chemistry. The certainly of that prediction will be greater when we source the chemistry from all the same materials (and less when we introduce new ones).

Insight-live's ability to show side-by-side recipe chemistry and physics makes it a natural for studying one in relation to another with respect to melting and softening behavior. Technicians build a knowledge of what types of chemistry changes are most effective in altering melting temperature without unduly affecting other properties and how this relates to the materials that are sourcing that chemistry. With experience you will develop the ability to predict the range in which a glaze might be useful in your circumstances better than any algorithm could do.

For these reasons we have been very hesitant to build temperature prediction into our software.

Related Information

A frit softens over a wide temperature range

This picture has its own page with more detail, click here to see it.

Raw materials often have a specific melting temperature (or they melt quickly over a narrow temperature range). We can use the GLFL test to demonstrate the development of melt fluidity between a frit and a raw material. On the left we see five flows of boron Ferro Frit 3195, across 200 degrees F. Its melting pattern is slow and continuous: It starts flowing at 1550F (although it began to turn to a glass at 1500F) and is falling off the bottom of the runway by 1750F. The Gerstley Borate (GB), on the other hand, goes from no melting at 1600F to flowing off the bottom by 1625F! But GB has a complex melting pattern, there is more to its story. Notice the flow at 1625F is not transparent, that is because the Ulexite mineral within GB has melted but its Colemanite has not. Later, at 1700F, the Colemanite melts and the glass becomes transparent. Technicians call this melting behaviour "phase transition", that does not happen with the frit.

Frits melt so much better than raw materials

This picture has its own page with more detail, click here to see it.

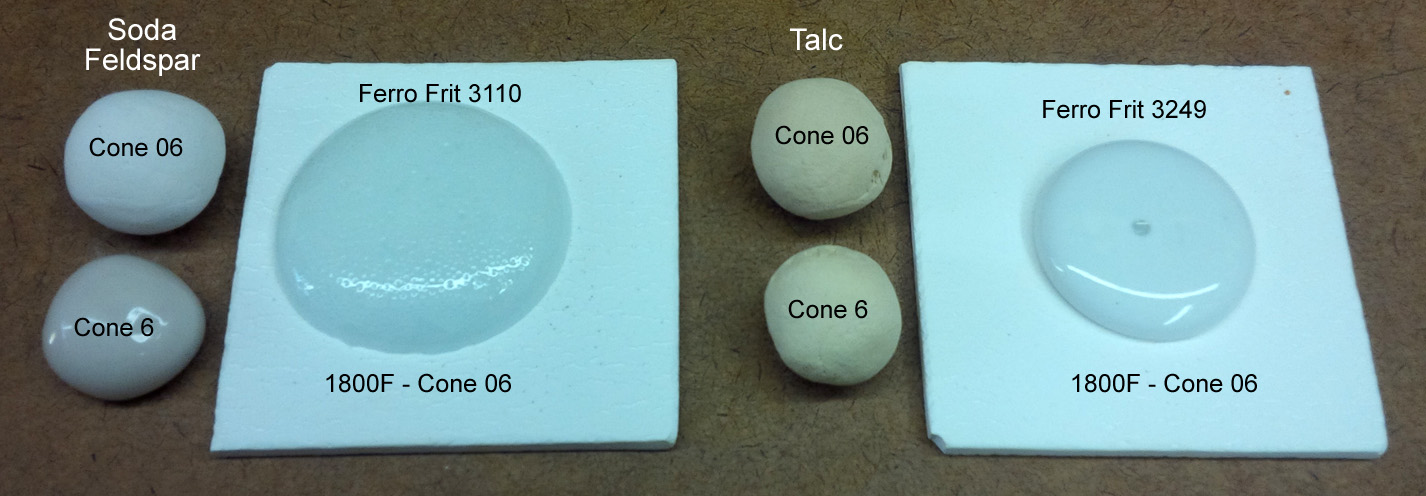

Feldspar and talc are both flux sources (glaze melters), they are common in all types of stoneware glazes. But their fluxing oxides, Na2O and MgO, are locked in crystal structures that neither melt early or supply other oxides with which they like to interact. The pure feldspar is only beginning to soften at cone 6. Yet the soda frit is already very active at cone 06! As high as cone 6, talc (the best source of MgO) shows no signs of melting activity at all. But a high-MgO frit is melting beautifully at cone 06! The frits progressively soften, starting from low temperatures, both because they have been premelted and have significant boron content. In both, the Na2O and MgO are free to impose themselves as fluxes, actively participating in the softening process.

How do metal oxides compare in their degrees of melting?

This picture has its own page with more detail, click here to see it.

These metal oxides have been mixed with 50% Ferro frit 3134 and fired to cone 6 oxidation. Chrome and rutile have not melted, copper and cobalt are extremely active melters, frothing and boiling. Cobalt and copper have crystallized during cooling. Manganese has formed an iridescent glass.

The same glaze fired at 1850F and 2200F

This picture has its own page with more detail, click here to see it.

This is G3806F copper green glaze. It is highly melt fluid at cone 6. As the glaze begins to melt notice that it splits on the sharp concave sections on the handle join. The underscore the needs for the melt to be sufficiently fluid to flow back in and heal these areas.

Why fast fire glazes employ zinc - a melt fluidity test tells us

This picture has its own page with more detail, click here to see it.

We are comparing the degree of melt fluidity (10 gram GBMF test balls melted down onto a tile) between two base clear glazes fired to cone 6 (top) and cone 1 (bottom).

Left: G2926B clear boron-fluxed (0.33 molar) clear base glaze sold by Plainsman Clays.

Right: G3814 zinc-fluxed (0.19 molar) clear base.

Two things are clear: Zinc is a powerful flux (it only takes 5% in the recipe to yield the 0.19 molar). Zinc melts late: Notice that the boron-fluxed glaze is already flowing well at cone 1, whereas the zinc one has not even started. This is very good for fast fire because the unmelted glaze will pass more gases of decomposition from the body before it melts, producing fewer glaze defects.

Glossy blacks are best made adding a black stain to a quality base transparent

This picture has its own page with more detail, click here to see it.

The glaze on the left is called Tenmoku Cone 6 (a popular, and old, CM recipe). It is 20% calcium carbonate, 35% Custer feldspar, 15% OM4 Ball Clay and 30% silica, 10% iron oxide. If you have any experience with glaze you will note two things that a fishy here: There is no boron, lithia or zinc sourcing material. How can this melt enough at cone 6? It looks melted, but the ease of scratching it shows it is not. So, it appears that if we saturate an incompletely melted glaze with a lot of refractory brown colorant on a dark body the effect can be black. A better idea is the glaze on the right. We start with a stable, reliable base transparent, G2926B. Then we add 5% Mason 6666 black stain (stains are smelted at high temperatures, quenched and ground, they are inert and relatively safe). A bonus is we end up with a slurry that is not nearly as messy to use and does not turn into a bucket of jelly.

Can a cone 6 functional glaze having only whiting and feldspar melt enough?

This picture has its own page with more detail, click here to see it.

This flow test compares the base and base-plus-iron version of a popular CM recipe called "Tenmoku Cone 6" (20% whiting, 35% Custer feldspar, 15% Ball Clay and 30% silica, 10% iron oxide). Although iron is not a flux in oxidation, it appears to be doing exactly that here (that flow is just bubbling its way down the runway, the white one also fires to a glassy surface on ware). It looks melted in the tray on the right but notice how easily it is scratching on the tile (lower left). This demonstrates that looks can be deceiving. Cone 6 functional glazes always have some percentage of a power flux (like boron, lithia, zinc), otherwise they just do not melt into a hard glass. Maybe a glaze looks melted, but it has poor durability.

Flow tester tells me if I have overfluxed the glaze

This picture has its own page with more detail, click here to see it.

This is important because I am searching for a balance between the degree of melt fluidity of my original crazing glaze but having a thermal expansion to fit my porcelain (this is G3806E and F). With each adjustment to the chemistry to drop the thermal expansion I do a firing to compare the melt fluidity with the previous iteration. On the right I have too much boron, it’s melting more than I want. And bubbling.

The difference between Silica 90 and Silica 45 will affect the glaze melt

This picture has its own page with more detail, click here to see it.

Quartz particles have a high melting point, they must enter the glaze melt by being dissolved by it (usually the last particles to do so). Obviously, the silica should be as fine as possible to increase its surface area to be more readily dissolved. The more that dissolves the closer the physical properties of the fired glaze will be to the theoretical (e.g. degree of melting, thermal expansion, transparency, durability). This brand of silica, #90 classifies as 200 mesh even though 2.8% remains on the 200 mesh screen. Not surprisingly, their #45 grade retains 1.9% on the 325 mesh screen. However, the most significant aspect is how much of the #90 is on the 325 and 270 mesh screens: 26%. The #45 grade only retains 2.6% on them! This is a huge difference and shows the value of using the finer material. It would take a typical ball mill hours to make this difference.

Inbound Photo Links

Melting range is mainly about boron content |

Links

| Glossary |

Oxide System

|

| Glossary |

Phase Separation

Phase separation is a phenomenon that occurs in transparent ceramic glazes. Discontinuities in the internal glass matrix affect clarity and color. |

| Glossary |

Melt Fluidity

Ceramic glazes melt and flow according to their chemistry, particle size and mineralogy. Observing and measuring the nature and amount of flow is important in understanding them. |

| Articles |

The Chemistry, Physics and Manufacturing of Glaze Frits

A detailed discussion of the oxides and their purposes, crystallization, phase separation, thermal expansion, solubility, opacity, matteness, batching, melting. |

| Articles |

What Determines a Glaze's Firing Temperature?

The oxides contributed by glaze materials determine its chemistry. The chemistry is the main factor determining melting behaviour. But the particle sizes, shapes and mineralogies also come in to play. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy