| Monthly Tech-Tip | No tracking! No ads! |

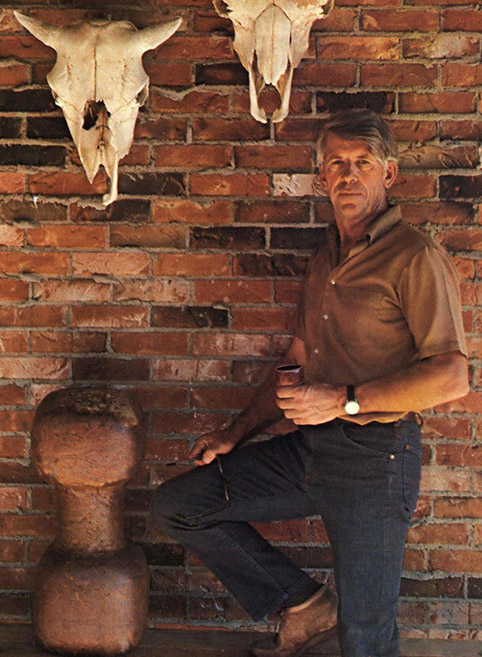

Luke Lindoe in 1971

He was the founder of Plainsman Clays. My dad had just built the Plainsman Clays factory for him and I began working there in 1972 (this picture was taken at his house, which my father also built). He was a well-known artist potter and sculptor at the time, having come out of the pottery production industry in the area. He got me started along the fascinating road of understanding the physics of clays. He was a true "plains man", interested in the geology of the plains (notice the skulls, these inspired the Plainsman logo). He got me started doing physical testing of raw clays (that he was finding everywhere). I was blown away by the fact that I could assess a completely new material and judge its suitability for many types of ceramic products and processes by doing the simple physical tests he showed me. It got started writing software to log the data for that back in the 1980s, that eventually led to digitalfire.com and Insight-live.com.

Related Pictures

Mosaic mural in Dan McCharles Park - made by Luke Lindoe in 1961

This picture has its own page with more detail, click here to see it.

The mural is made from unglazed stained stoneware tiles, each cut to shape. The inscription reads: "THE DOCTOR OF TODAY TAKES HIS PLACE AT THE HEAD OF A VERY LONG LINE OF DISTINGUISHED PREDECESSORS; THE KNOWLEDGE AND TRADITION THAY MAKES THE MEDICAL PROFESSION WHAT IT IS TODAY GROWS FROM

THE GREAT DOCTORS OF THE NINETEENTH CENTURY AND OF MEDIEVAL EUROPE, OF GREECE, OF EGYPT AND BEYOND - LOST IN THE PAST. THIS MOSAIC PAYS TRIBUTE TO THAT VAST HISTORY."

A gas kiln built by Luke Lindoe in the 1960s is still used at Plainsman Clays today

This picture has its own page with more detail, click here to see it.

It fires very evenly from top to bottom and front to back. We have used it for quality control to fire thousands of porosity and shrinkage test bars to monitor the maturity of the clay bodies. Oh, we also fire pottery in this!

Small bowl by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Cone 10R. H435 or H550 clay. Tenmoku glaze.

Slab vessel by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Cone 10R. Copper red glaze. P580 clay or P580G clay.

Slab vessel by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Cone 10R fired. H440G clay.

Bowl base by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Luke made hundreds of these small bowls for testing. He used a code number system to identify thing in his records.

Barium blue slab plate by by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Cone 10R fired. H441G clay. About 14" long.

John Porter’s fired glaze samples are being catalogued

This picture has its own page with more detail, click here to see it.

John Porter was a prolific glaze tester and developer, both in reduction and oxidation firing. We shot and cataloged hundreds of pictures of a treasure trove of glaze samples of his testing from the 1970s to the 1990s. Among them are also a few samples done by Luke Lindoe. Each of the many hundreds of specimens was code-numbered to index into John's meticulous notes. This was a time when most pottery was done at temperatures where little frit was needed, glazes were made of raw minerals. Hopefully, more cataloguing of our archives will uncover more of his notes and provide clues and information to derive more of the recipes of these.

Large sculpture by Luke Lindoe - 1967

This picture has its own page with more detail, click here to see it.

This is housed on the lower floor of the Medicine Hat public library. It is a testimony to the skill Luke Lindoe, this heavy piece has no visible cracks. Made at the time Plainsman Clays was just starting. Luke did not have a high-temperature red burning clay to be able to make the warm colors of H440, for example (this employs the clays available in the I-XL Brick suite of raw materials). He did have materials mined around Elkwater, two of them he could have used were 45R, a low-fire red similar to BGP, and 45D, a medium-fire plastic material. These types of materials would have limited firing temperature to around cone 2. But Luke would also have been aware of the more refractory clays around Ravenscrag, Sask and could have been processing them himself - that would have enabled a high-temperature body for gas firing in a reduction atmosphere.

Celadon slab plate by by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Slab vase by by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Sculpture by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Slab plate by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Clay is P580G. Pressed plant design. Matte blue glaze that varies tone by thickness. About 12" length.

Bowl by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Fired at cone 10R. H440 clay. White matte glaze. About 10in diameter.

Sculptural piece by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Likely cone 10R fired. Other factors (e.g. clay body, glaze) unknown.

Sculptural piece by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Unglazed. Fired at cone 6R using H440 clay. Likely made in the early 1990s.

Sculptural piece by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Unglaze. Fired at cone 6R. Made with H440 clay. Likely done during the 1990s.

Gradient test bars show how a range of temperatures affects a clay

This picture has its own page with more detail, click here to see it.

These are the fronts and backs of dust-pressed and fired gradient bars. They were done by Luke Lindoe in the I-XL brick lab to assess the firing history on two clay samples from Montana. After final drying, the bar width at each line is carefully recorded. They are fired horizontally in a furnace capable of reproducing linear thermal gradients along the length of the bar (equally spaced thermocouples enable control in each micro-zone). After firing, the widths are re-measured. The data produces a graph of fired shrinkage vs. temperature. Bars can also be visually inspected side-by-side for differences (color being the most obvious but also surface character). This method of comparatively assessing the effect of temperature on a clay test bar is popular in the brick industry (e.g. when a new mining of clay is being compared with a previous one). However, the SHAB test, although requiring more effort, provides more information and is more accurate (e.g. for pottery and porcelain).

Measuring clay test bars done by Luke Lindoe 40 years ago

This picture has its own page with more detail, click here to see it.

Luke Lindoe prospected Montana and Idaho for clays during the 1970s. He found an amazing variety of fireclays, earthenwares and stonewares. Every color, texture, plasticity. For each he made test bars to fire at different temperatures. Our M2 and Troy clays originated from this work. We just found these bars, but do not have Luke's shrinkage and porosity data, so are measuring them now. He code-numbered each and stamped them with four-inch marks. So we can derive the total fired shrinkages and measure the porosities. We can tell a lot about the plasticity of each by the nature of the cut lines. The texture also is obvious. Now we just need to start searching Luke's map archives to find out where all of these are.

Sculptural piece by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Copper red glaze fired at cone 10R. Clay is like P580. Made in Luke's home studio during the 1990s.

Sculptural piece by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Cone 10R. Likely made using H550 or P580. Rutile blue melt fluid glaze. Made during the 1990s.

Sculptural piece by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Cone 10R. Copper red highly melt fluid glaze. Made during the 1990s.

Plate by Luke Lindoe

This picture has its own page with more detail, click here to see it.

6.88 x 36.25 cm. Donated by the Estate of Luke Lindoe to the Collection of the Esplanade Art Gallery. Clay is H443. Barium blue glaze. Fired at cone 10R.

Incised iron reduction fired vase by Luke Lindoe

This picture has its own page with more detail, click here to see it.

28.75 x 25 cm. Donated by the Estate of Luke Lindoe to the Collection of the Esplanade Art Gallery. Luke made these during the 1970s using Plainsman H440 and H443. The white slip is the raw 3C clay and the red patches are a red leaded glaze third-fired on at cone 04. For these he also decorated using liquid bright gold lustres.

Barium blue vase by Luke Lindoe

This picture has its own page with more detail, click here to see it.

31.25 x 17.5 cm. Donated by the Estate of Luke Lindoe to the Collection of the Esplanade Art Gallery. H42 or H40 clay. Barium blue glaze. Fired at cone 10R.

Ash Tray by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Fired in the brick kiln at I-XL industries. Iron-bearing vitreous body, likely made using 45R and RBD. The glaze is likely his S2 recipe, bleeding of the iron from the body is browning it.

Ashtry by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Likely fired in the brick tunnel kiln at I-XL industries, using one of their buff burning clay bodies. The glaze is likely S2.

Ash Tray by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Fired in the I-XL brick kiln. The red-burning clay body is likely made using 45R. It is being fired to a high degree of maturity.

Crazed iron reduction fired vase by Luke Lindoe

This picture has its own page with more detail, click here to see it.

The glaze is made from nearly 100% nepheline syenite, thus guaranteeing that it would craze. The piece was fired at cone 6 reduction using cone 10R bodies, achieving a redder fired color (because of low vitrification). The clay body is H440. These types of pieces were made during the 1970s and 1980s.

Bowl by by Luke Lindoe

This picture has its own page with more detail, click here to see it.

Fired at cone 10R. Approx 10 inch diameter. The body is likely similar to H441G, but Luke added particulate iron stone concretions to greatly increase the reduction speckle. This is likely his S2 glaze recipe.

Buffalo skull that inspired the Plainsman logo

This picture has its own page with more detail, click here to see it.

This in on display at the visitor center of the Grasslands National Park in Val Marie, Saskatchewan. Perhaps ones like this formed part of the inspiration Luke Lindoe had when conceiving of the logo for the company he would form. To us, this area is "clay country", but to tourists it is a place to see the living prairie and also history like dinosaur fossils, the mass extinction boundary, hearth sites, tipi rings, bison drive lanes, and cellar depressions.

Videos

Links

| Articles |

Ravenscrag Slip is Born

The story of how Ravenscrag Slip was discovered and developed might help you to recognize the potential in clays that you have access to. |

| URLs |

http://en.m.wikipedia.org/wiki/Luke_Lindoe

Luke Lindoe at Wikipedia |

| Glossary |

Plainsman Clays

A clay mining and processing company in Southern Alberta since 1965. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy