| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

John Porter’s fired glaze samples are being catalogued

John Porter was a prolific glaze tester and developer, both in reduction and oxidation firing. We shot and cataloged hundreds of pictures of a treasure trove of glaze samples of his testing from the 1970s to the 1990s. Among them are also a few samples done by Luke Lindoe. Each of the many hundreds of specimens was code-numbered to index into John's meticulous notes. This was a time when most pottery was done at temperatures where little frit was needed, glazes were made of raw minerals. Hopefully, more cataloguing of our archives will uncover more of his notes and provide clues and information to derive more of the recipes of these.

Related Pictures

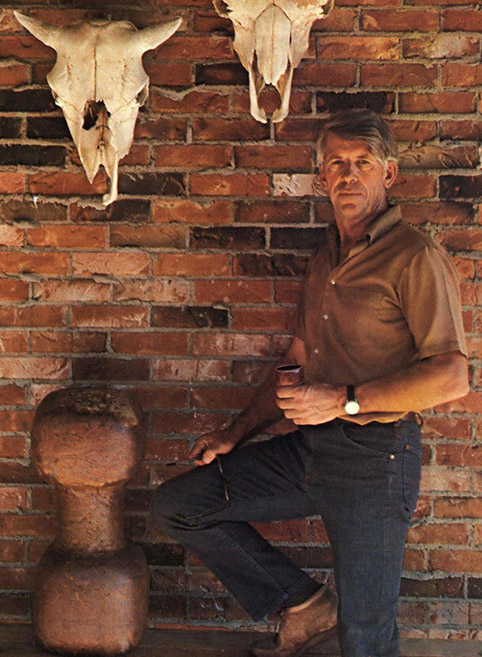

Luke Lindoe in 1971

This picture has its own page with more detail, click here to see it.

He was the founder of Plainsman Clays. My dad had just built the Plainsman Clays factory for him and I began working there in 1972 (this picture was taken at his house, which my father also built). He was a well-known artist potter and sculptor at the time, having come out of the pottery production industry in the area. He got me started along the fascinating road of understanding the physics of clays. He was a true "plains man", interested in the geology of the plains (notice the skulls, these inspired the Plainsman logo). He got me started doing physical testing of raw clays (that he was finding everywhere). I was blown away by the fact that I could assess a completely new material and judge its suitability for many types of ceramic products and processes by doing the simple physical tests he showed me. It got started writing software to log the data for that back in the 1980s, that eventually led to digitalfire.com and Insight-live.com.

Measuring clay test bars done by Luke Lindoe 40 years ago

This picture has its own page with more detail, click here to see it.

Luke Lindoe prospected Montana and Idaho for clays during the 1970s. He found an amazing variety of fireclays, earthenwares and stonewares. Every color, texture, plasticity. For each he made test bars to fire at different temperatures. Our M2 and Troy clays originated from this work. We just found these bars, but do not have Luke's shrinkage and porosity data, so are measuring them now. He code-numbered each and stamped them with four-inch marks. So we can derive the total fired shrinkages and measure the porosities. We can tell a lot about the plasticity of each by the nature of the cut lines. The texture also is obvious. Now we just need to start searching Luke's map archives to find out where all of these are.

John Porter visiting Plainsman Clays in 2023

This picture has its own page with more detail, click here to see it.

John took us kids under his wing way back in the early 1970s and we have all been here ever since, working together since he left in the late 70s. Left to right: Joe Schmidt, my lab co-worker; Tim Lerner, our purchasing agent; Kirk Miller, production foreman; John Porter and me, Tony Hansen.

Videos

Links

| Glossary |

Code Numbering

In a ceramics lab, studio or classroom specimens of hundreds of glazes and bodies may be present. A code numbering system that links these to written or computer records is essential. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy