| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Mosaic mural in Dan McCharles Park - made by Luke Lindoe in 1961

The mural is made from unglazed stained stoneware tiles, each cut to shape. The inscription reads: "THE DOCTOR OF TODAY TAKES HIS PLACE AT THE HEAD OF A VERY LONG LINE OF DISTINGUISHED PREDECESSORS; THE KNOWLEDGE AND TRADITION THAY MAKES THE MEDICAL PROFESSION WHAT IT IS TODAY GROWS FROM

THE GREAT DOCTORS OF THE NINETEENTH CENTURY AND OF MEDIEVAL EUROPE, OF GREECE, OF EGYPT AND BEYOND - LOST IN THE PAST. THIS MOSAIC PAYS TRIBUTE TO THAT VAST HISTORY."

Related Pictures

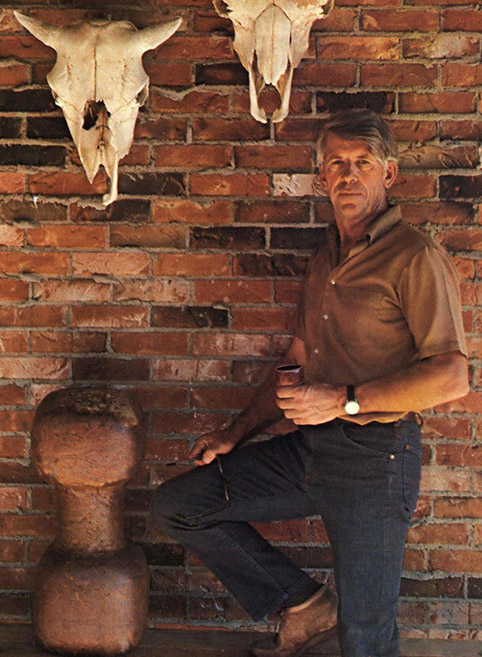

Luke Lindoe in 1971

This picture has its own page with more detail, click here to see it.

He was the founder of Plainsman Clays. My dad had just built the Plainsman Clays factory for him and I began working there in 1972 (this picture was taken at his house, which my father also built). He was a well-known artist potter and sculptor at the time, having come out of the pottery production industry in the area. He got me started along the fascinating road of understanding the physics of clays. He was a true "plains man", interested in the geology of the plains (notice the skulls, these inspired the Plainsman logo). He got me started doing physical testing of raw clays (that he was finding everywhere). I was blown away by the fact that I could assess a completely new material and judge its suitability for many types of ceramic products and processes by doing the simple physical tests he showed me. It got started writing software to log the data for that back in the 1980s, that eventually led to digitalfire.com and Insight-live.com.

Incised iron reduction fired vase by Luke Lindoe

This picture has its own page with more detail, click here to see it.

28.75 x 25 cm. Donated by the Estate of Luke Lindoe to the Collection of the Esplanade Art Gallery. Luke made these during the 1970s using Plainsman H440 and H443. The white slip is the raw 3C clay and the red patches are a red leaded glaze third-fired on at cone 04. For these he also decorated using liquid bright gold lustres.

Crazed iron reduction fired vase by Luke Lindoe

This picture has its own page with more detail, click here to see it.

The glaze is made from nearly 100% nepheline syenite, thus guaranteeing that it would craze. The piece was fired at cone 6 reduction using cone 10R bodies, achieving a redder fired color (because of low vitrification). The clay body is H440. These types of pieces were made during the 1970s and 1980s.

A gas kiln built by Luke Lindoe in the 1960s is still used at Plainsman Clays today

This picture has its own page with more detail, click here to see it.

It fires very evenly from top to bottom and front to back. We have used it for quality control to fire thousands of porosity and shrinkage test bars to monitor the maturity of the clay bodies. Oh, we also fire pottery in this!

Measuring clay test bars done by Luke Lindoe 40 years ago

This picture has its own page with more detail, click here to see it.

Luke Lindoe prospected Montana and Idaho for clays during the 1970s. He found an amazing variety of fireclays, earthenwares and stonewares. Every color, texture, plasticity. For each he made test bars to fire at different temperatures. Our M2 and Troy clays originated from this work. We just found these bars, but do not have Luke's shrinkage and porosity data, so are measuring them now. He code-numbered each and stamped them with four-inch marks. So we can derive the total fired shrinkages and measure the porosities. We can tell a lot about the plasticity of each by the nature of the cut lines. The texture also is obvious. Now we just need to start searching Luke's map archives to find out where all of these are.

Large sculpture by Luke Lindoe - 1967

This picture has its own page with more detail, click here to see it.

This is housed on the lower floor of the Medicine Hat public library. It is a testimony to the skill Luke Lindoe, this heavy piece has no visible cracks. Made at the time Plainsman Clays was just starting. Luke did not have a high-temperature red burning clay to be able to make the warm colors of H440, for example (this employs the clays available in the I-XL Brick suite of raw materials). He did have materials mined around Elkwater, two of them he could have used were 45R, a low-fire red similar to BGP, and 45D, a medium-fire plastic material. These types of materials would have limited firing temperature to around cone 2. But Luke would also have been aware of the more refractory clays around Ravenscrag, Sask and could have been processing them himself - that would have enabled a high-temperature body for gas firing in a reduction atmosphere.

Videos

Links

| URLs |

http://en.m.wikipedia.org/wiki/Luke_Lindoe

Luke Lindoe at Wikipedia |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy