| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Oxidation Firing

In ceramics, this term is most often used to refer to kilns firing with an atmosphere having available oxygen to react with glaze and body surfaces during firing

Key phrases linking here: oxidation firing - Learn more

Details

A firing where the atmosphere inside the kiln has sufficient supplies of oxygen to react with the glaze and clay body surfaces (and thus produce the colors characteristic of this). Electric kilns are synonymous with oxidation firing. However these kilns lack the air flow of their gas counterparts. Stagnant air inside can be saturated with carbon and other products of decomposition from bodies and glazes and these can use up oxygen in the chamber. This produces more neutral atmosphere than intended or realized (especially if glaze and body materials have high LOIs). Directly-connected kiln vents improve this situation but still do not approach the ventilation in gas kilns.

Oxidation glazes are typically more brightly colored than reduction ones, especially at lower temperatures. Iron (Fe2O3) is not a flux in oxidation kilns. Generally, potters and hobbyists who employ reduction in their kilns, fire at higher temperatures.

Industries that use periodic and tunnel kilns for fast-fire typically fire in oxidation or neutral atmospheres.

Related Information

The same glaze in reduction (left) and oxidation at cone 10

This picture has its own page with more detail, click here to see it.

It is not just iron oxide that changes character from oxidation to reduction. Of course, cobalt can fire to a bright blue in oxidation also, but this will only happen if its host glaze is glossy and transparent. In this case the shift to reduction has altered the character of the glaze enough so that its matte character subdues the blue.

How reduction firing can affect glaze color

This picture has its own page with more detail, click here to see it.

An example of how the same dolomite cobalt blue glaze fires much darker in oxidation than reduction. But the surface character is the same. A different base glaze having the same colorant might fire much more similar. The percentage of colorant can also be a factor in how similar they will appear. The identity of the colorant is important, some are less prone to differences in kiln atmosphere. Color interactions are also a factor. The rule? There is none, it depends on the chemistry of the host glaze, which color and how much there is.

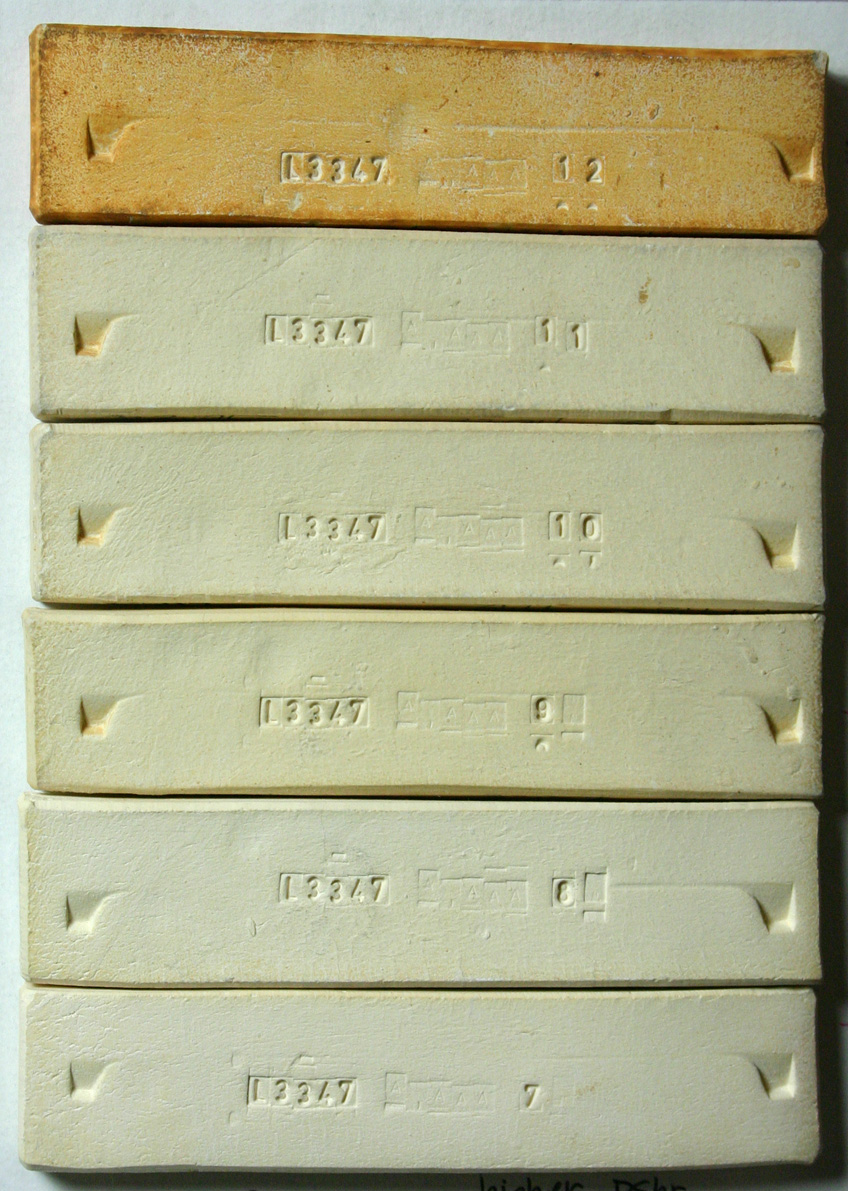

Gleason ball clay fired test bars from cone 7-11 oxidation and cone 10 reduction

This picture has its own page with more detail, click here to see it.

The oxidation bars (lower) are typical of most ball clays. They burn off-white and darken slightly in color as they approach maturity (above cone 10). Ball clays are fairly refractory, often as much more more than common fireclays. Ball clays almost always have some soluble salts and these reveal themselves in reduction firing (top bar).

Cone 5 reduction mug (left) and cone 6 oxidation mug (right)

This picture has its own page with more detail, click here to see it.

These are made from Plainsman M340 and have transparent glazes. Notice the grey color of reduction vs. the yellowish of oxidation.

Difference between oxidation and reduction! GR10-C matte on Plainsman H443

This picture has its own page with more detail, click here to see it.

Same body, same glaze. Left is cone 10 oxidation, right is cone 10 reduction. What a difference! This is a Ravenscrag-Slip-based recipe on a high-fire iron stoneware. In reduction, the iron oxide in the body and glaze darkens (especially the body) and melts much more. The behavior of the tin oxide opacifier is also much different (having very little opacifying effect in reduction).

Links

| Glossary |

Reduction Firing

A method of firing stoneware where the kiln air intakes and burners are set to restrict or eliminate oxygen in the kiln such that metallic oxides convert to their reduced metallic state. |

| Glossary |

LOI

Loss on Ignition is a number that appears on the data sheets of ceramic materials. It refers to the amount of weight the material loses as it decomposes to release water vapor and various gases during firing. |

| Typecodes |

Oxidation Firing

|

| Articles |

Electric Hobby Kilns: What You Need to Know

Electric hobby kilns are certainly not up to the quality and capability of small industrial electric kilns, being aware of the limitations and keeping them in good repair is very important. |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy