| Monthly Tech-Tip | No tracking! No ads! | |

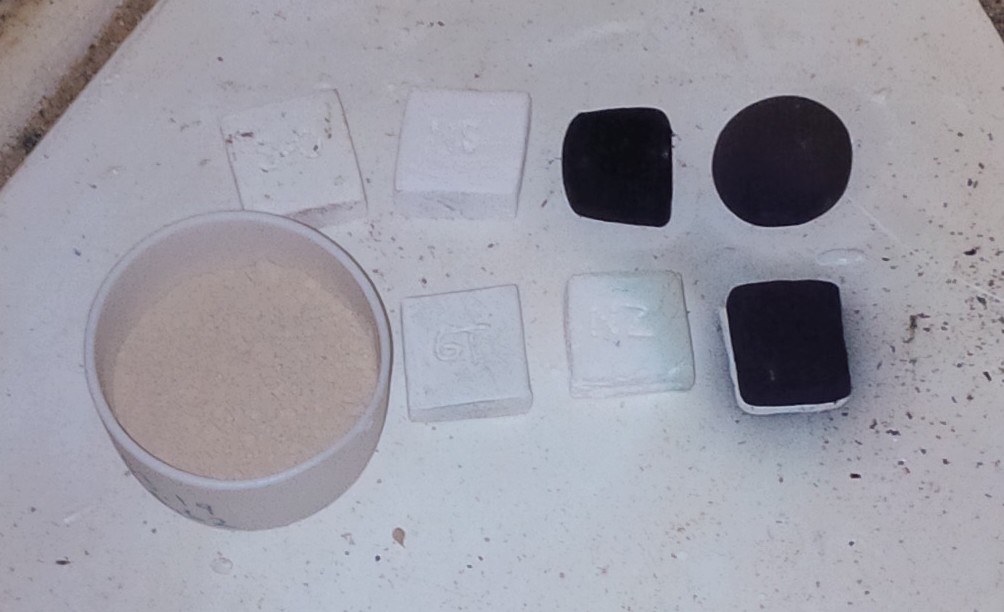

LOI test of common materials flags copper carbonate

These are pure samples (with 2% binder added) of (top left to bottom right) strontium carbonate, nepheline syenite, cobalt carbonate, manganese dioxide, bentonite (in bowl), 6 Tile kaolin, New Zealand kaolin and copper carbonate. I am firing them at 50F increments from 1500F and weighing to calculate loss on ignition for each. I want to find out at what temperature they are gassing (and potentially bubble-disrupting the glaze they are in or under). Notice how the copper is fuming and spitting black specks on the shelf, this happens right around 1500F (these stains on the shelf darkened considerably when the kiln was fired higher). Yet copper carbonate does not melt and fully decompose until much higher. No wonder it is implicated in cases of glaze blistering and bubbling.

Videos

Links

| Materials |

Copper Carbonate

A source of CuO copper oxide used in ceramic glazes to produce a variety of colors (used only or with other colorants). |

| Materials |

Copper Carbonate Basic

This form of copper carbonate is the article of commerce, a mixture of theoretical copper carbonate and copper hydroxide. |

| Materials |

Strontium Carbonate

A pure source of SrO for ceramic glazes. It contains 70% SrO and has an LOI of 30% (released as CO2 during firing). |

| Temperatures | Decarbonation (200-1000) |

| Oxides | LOI - Loss on Ignition |

| Glossary |

Dimpled glaze

A ceramic glaze defect characterized by tiny holes in the surface, often too small to see with the naked eye. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy