| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Strontium Carbonate

Alternate Names: Strontianite

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| SrO | 70.20% | 1.00 | |

| CO2 | 29.80% | n/a | |

| Oxide Weight | 103.60 | ||

| Formula Weight | 147.58 | ||

Notes

Strontium Carbonate is a very slightly soluble source of SrO used in ceramic glazes.

Strontium is considered a safe material. Some people confuse SrO with Strontium 90, an isotope released from atomic reactions; they are not the same thing. The raw powder is low-dusting and pleasant to work with. There is disagreement about when it decomposes (data sheets vary from 1075-1100C, one even indicates 1340C) as follows:

SrCO3 -> SrO + CO2

The 'Ceramic Industry Materials Handbook' states that it starts to disassociate as early as 800C in a purely oxidizing atmosphere, whereas a CO2 atmosphere might delay break-down until around 1220C. This information is supported by the fact that when the more stable calcium and barium carbonate are added to bodies, pinholing and blistering are greater than bodies containing strontium. Wikipedia says it melts and decomposes at the same time, 1100C.

Strontium carbonate is often recommended as a substitute for barium to produce matte glazes. Use about 75% as much and test first to make sure color response is the same. However, strontium is not a substitute for barium as a precipitator of soluble salts in clay bodies because it combines with SO4-- ions in the water to form a compound that is not nearly as insoluble as BaSO4.

Viscous zirconium silicate glazes can be smoothed with the addition of strontium carbonate.

As noted, strontium carbonate produces gases as it decomposes and these can cause pinholes or blisters in glazes (if they are being generated into a glaze melt having a viscosity and surface tension that is unable to pass them or heal over properly as they escape or one that simply does not have time because of quick cooling). There are strontium frits available (e.g. Fusion F-581 has 39% SrO) and incorporating one of them to source it instead of raw strontium carbonate (a classic job for glaze chemistry calculations). The resultant glaze will be more fusible and will have better clarity and fewer defects. Strontium frits have become much more common of late and are useful to producing brilliant transparent glazes without having a high expansion (like those based on Na2O and K2O). Please read the information about the oxide SrO to fully appreciate the value of SrO (especially when sourced from frits), not just as alternatives to this material, but as excellent ways to produce brilliant glazes.

Some pottery glazes have such high strontium carbonate percentages that a frit cannot supply the needed SrO. These are, of course, special-purpose formulations, having an SrO content that exceeds (or far exceeds) normal target or limit formulas. According to the Wikipedia article, while it does have a low solubility, this increases dramatically with temperature (about 50 times greater at 100C versus room temperature) and up to 100 times greater in the presence of CO2 in the slurry. Both of these factors play in glaze slurries (they can contain other carbonates that are disassociating) and thus indicate the potential to flocculate or deflocculate them.

Related Information

Strontium carbonate self destructing

This picture has its own page with more detail, click here to see it.

Strontium carbonate fired at 1800F and then allowed to rehydrate in the air for two days. It is crumbling like this all by itself, similar to what calcium carbonate does as it rehdrates.

Cone 6 porcelain marbled and thrown

This picture has its own page with more detail, click here to see it.

These bowls were made by Tony Hansen using a mixture of white and stained New-Zealand-kaolin-based porcelain (Plainsman Polar Ice) fired at cone 6. The body is not only white, but very translucent.

Original container bag of Seaforth Mineral Strontium Carbonate

This picture has its own page with more detail, click here to see it.

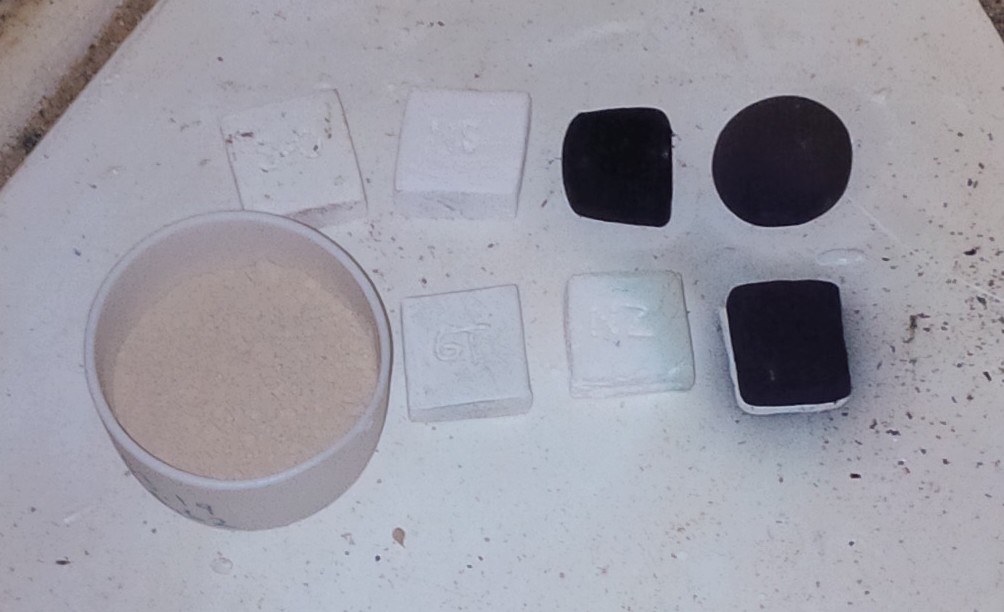

LOI test of common materials flags copper carbonate

This picture has its own page with more detail, click here to see it.

These are pure samples (with 2% binder added) of (top left to bottom right) strontium carbonate, nepheline syenite, cobalt carbonate, manganese dioxide, bentonite (in bowl), 6 Tile kaolin, New Zealand kaolin and copper carbonate. I am firing them at 50F increments from 1500F and weighing to calculate loss on ignition for each. I want to find out at what temperature they are gassing (and potentially bubble-disrupting the glaze they are in or under). Notice how the copper is fuming and spitting black specks on the shelf, this happens right around 1500F (these stains on the shelf darkened considerably when the kiln was fired higher). Yet copper carbonate does not melt and fully decompose until much higher. No wonder it is implicated in cases of glaze blistering and bubbling.

Orange-peel or pebbly glaze surface. Why?

This picture has its own page with more detail, click here to see it.

This is a cone 10 glossy glaze. It has the chemistry that suggests it should be crystal clear and smooth. But there are multiple issues with the materials supplying that chemistry: Strontium carbonate, talc and calcium carbonate. Each has a significant LOI and produces gases decomposition. When the gases need to come out at the wrong time it turns the glaze into a Swiss cheeze of micro-bubbles. A study to isolate which of these three materials is the problem might make it possible to adjust the firing to accommodate it. But probably not. The most obvious solution is to just use non-gassing sources MgO, SrO, CaO and BaO (which will require some calculation). There is a good reason to do this: The glaze contains some boron frit, that is likely kick-starting melting much earlier than a standard raw-material-only cone 10 glaze. That fluid melt may not only be trapping gases from the body but creating a perfect environment to trap all the bubbles coming out of those carbonates and talc. All of this being said, a drop and hold firing schedule could also smooth it out a lot.

Frits instead of raw zinc, lithium, barium, strontium

This picture has its own page with more detail, click here to see it.

Raw material sources of zinc, lithium, barium, strontium have issues (e.g. precipitates in glaze slurries, toxicity, high drying shrinkage and carbon burnoff that affect laydown and fired surface defects like pinholes, blisters, orange peeling, crystallization). Yet the oxides that these materials supply to the glaze melt - ZnO, Li2O, BaO and SrO, can be sourced from frits which melt much better and remove most of the problems. Consider examples made by Fusion:

-Frit F-493 has 11% Li2O

-F-403 has 35% BaO

-F-581 has 39% SrO

-FZ-16 has 15% ZnO

These frits source other oxides but such are common in most glazes and glaze calculation can be used to retain the overall chemistry. Although these are expensive, the benefits are game changers. But there is a problem: Potters can't get these. Therefore they have difficulty creating the dazzling visual effects of many commercial glazes.

Links

| Temperatures | Strontium carbonate decomposition (800-1100) |

| Temperatures | Strontium carbonate melts (1100-) |

| Hazards |

Strontium Carbonate Toxicity Note

Is there any radiation danger from using this material in ceramics? |

| Typecodes |

Generic Material

Generic materials are those with no brand name. Normally they are theoretical, the chemistry portrays what a specimen would be if it had no contamination. Generic materials are helpful in educational situations where students need to study material theory (later they graduate to dealing with real world materials). They are also helpful where the chemistry of an actual material is not known. Often the accuracy of calculations is sufficient using generic materials. |

| Typecodes |

Flux Source

Materials that source Na2O, K2O, Li2O, CaO, MgO and other fluxes but are not feldspars or frits. Remember that materials can be flux sources but also perform many other roles. For example, talc is a flux in high temperature glazes, but a matting agent in low temperatures ones. It can also be a flux, a filler and an expansion increaser in bodies. |

| URLs |

http://en.wikipedia.org/wiki/Strontium_carbonate

Strontium carbonate at Wikipedia |

| Oxides | SrO - Strontium Oxide, Strontia |

Data

| Bulk Density lbs/cu. ft. (Packed) | 105 |

|---|---|

| Hardness (Moh) | 3.6 |

| Frit Softening Point | 723C D |

| Density (Specific Gravity) | 3.6 |

| Density (Specific Gravity) | 4.00 |

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy