| Monthly Tech-Tip | No tracking! No ads! | |

Poor plaster release from 3D printed mug handle case molds

My objective was to continue skipping the making of a rubber case mold and 3D print them directly. Since 3D printed surfaces naturally part well from plaster and the artifacts, although visible, do not show on the final fired pieces, I even wanted to do this whole process without any sanding or oiling. However, despite printing a dozen or more variations, carefully controlling plaster/water ratios and waiting/mixing the recommended time periods, few good plaster molds were extracted without corner-breaking. Even painting the inner surface, oiling over it and beveling corners did resolve this issues. It seems that a combination of the printing artifacts, sharp corners, the handle perpendicular (because of the oval cross-section) and the inside negative shape all enabled the plaster to get a very firm grip on the PLA print. Although I could have resorted to a heat gun to soften the PLA material enough to pull it away I relented and decided to switch to making a block mold (for rubber) rather than a case mold (for plaster).

Related Pictures

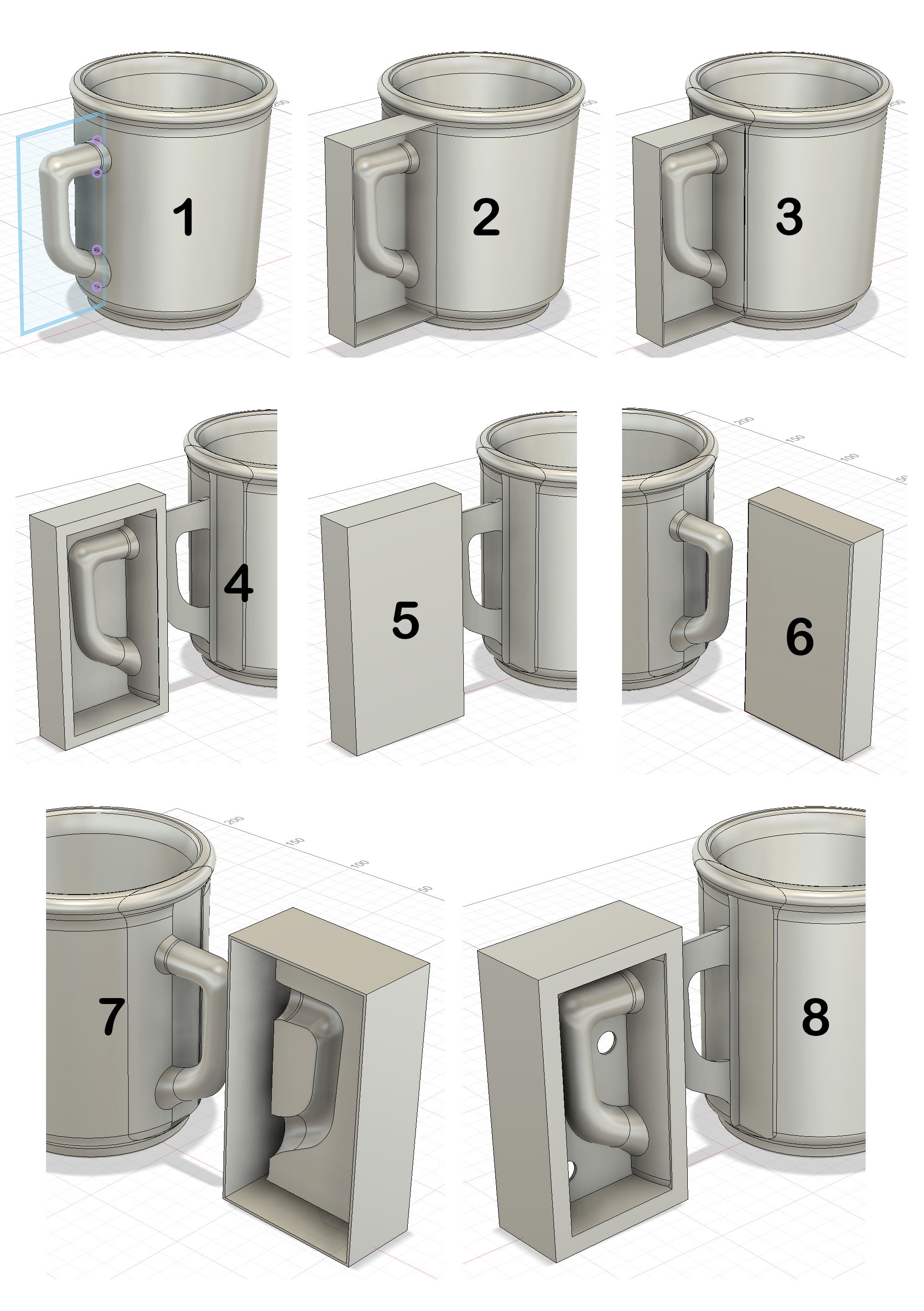

3D printing case vs block mug handle molds

This picture has its own page with more detail, click here to see it.

Top: Case molds (for pouring plaster into to make working molds) in the slicer about to be printed.

Bottom: Block molds (actually molds of block molds for pouring rubber into) about to be printed.

The top situation would have been a dream for a potter like me, the simplest possible way to introduce mold-making for slip casting into a process. However, my goal of print-and-pour was not met, this shape is not conducive to the extraction of the plaster without corner breaking. The block mold master (lower left) was made by pouring PMC-746 rubber into these molds. That works extremely well, there will be no problems making plaster molds with this. Notice how well it has preserved the printing artifacts, they look like wood grain. The white embeds enable inserting natches (that I make on the printer also).

CAD steps for a 3DP block mold to make a rubber case mold

This picture has its own page with more detail, click here to see it.

The objective was to make a rubber master case mold for the production of working plaster molds. 3DP is a great solution. This drawing was done in Fusion 360.

1: A make a sketch of a box, around the handle, on the XY plane. Offset that outward by 1.2mm (my printer prints 0.4mm wide, three passes give good strength).

2: Extrude to create box 1: The base backward by 1mm and the sides forward by 20mm.

3: Use five sides of the box as cutting planes to slice it out of the mug.

At this point I could print this in PLA filament, pour plaster into and then use a hair drier to peel it off. But let’s make rubber molds instead.

4: Move the box-with-handle away from the mug. Pull the four sides out by 5mm to thicken them.

5 & 6: Create box 2 around the outside of it, as a new body, 1.2mm wider and taller, 1mm more frontward and 1mm less backward.

7: Use box 1 as a cutter to remove material from box 2 and then pull the outer 1.2mm sides 5mm backward.

8: Shell out the back side to 1.2 wall thickness and make two 9.4mm holes (to accommodate natch clips).

To make side 2 mirror-image a new body using the front or back as the reflexion plane. The back side is then filled with PMC-746 rubber to make the block mold. Plaster is poured into that to make each working mold.

3D printing case vs block molds for ceramics

This picture has its own page with more detail, click here to see it.

Left are case molds, they are made by 3D printing the positive profile on a backplate (with holes for natches). These are secured into slotted rails. Right is a block mold, it is made by 3D printing the profile of a working mold with integrated rails. This one is printed vertically in four pieces. It is held together and straight with printed brackets. We pour rubber into these to make case molds. Each method has advantages and issues.

-Case: Faster to print. Easier to draw. Joins cast as easily removed bumps on the working molds. This is only suitable for prototyping, making one working mold.

-Block: Much more attention is needed in printing, there are more issues with orientation of print, infill, printed support, multi-piecing, fit and seam-filling. 3D drawing of these is more difficult. And block molds are bigger because they are molds of molds. They also need to be more precise to merit the cost of the rubber.

Videos

Links

| Typecodes |

3D printing problems

3D design and printing for mold making in ceramics bring exciting new capabilities. Awareness of the issues and knowing how to mitigate each is a must. 3D is resetting all fabrication industries and engineers are solving every problem, you can too. |

| Projects |

2019 Jiggering-Casting Project of Medalta 66 Mug

My project to reproduce a mug made by Medalta Potteries more than 50 years ago. I cast the body and handle, jigger the rim and then attach the handle. 3D printing made this all possible. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy