| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

EP Kaolin

Alternate Names: EPK, Edgar Plastic Kaolin, EPK Kaolin

Description: Plastic White Firing Kaolin

| Oxide | Analysis | Formula | Tolerance |

|---|---|---|---|

| CaO | 0.18% | 0.01 | |

| K2O | 0.33% | 0.01 | |

| MgO | 0.10% | 0.01 | |

| Na2O | 0.06% | - | |

| TiO2 | 0.37% | 0.01 | |

| Al2O3 | 37.36% | 1.00 | |

| P2O5 | 0.24% | - | |

| SiO2 | 45.73% | 2.08 | |

| Fe2O3 | 0.79% | 0.01 | |

| LOI | 13.20% | n/a | |

| H2O | 1.40% | n/a | |

| SO3 | 0.21% | n/a | |

| Oxide Weight | 232.50 | ||

| Formula Weight | 272.92 | ||

Notes

If you have issues getting this there are alternatives. If EPK is being used in a glaze and the percentage is low (e.g. 10-20%) switching to another will likely have minimal effect on fired properties. However, slurry properties might change. EPK helped dipping glaze slurries to gel, making them thixotropic. It was also sticky. Both Grolleg and New Zealand kaolin impart similar properties. Up to about 25% could be tolerated in glazes before drying cracks became an issue. Pioneer kaolin didn’t gel but plasticity was about the same. #6 Tile kaolin is far more plastic and, like Pioneer, but isn’t thixotropic, 20% may be the maximum to avoid drying cracks (if more kaolin is needed or there are other plastics in the recipe, e.g. Gerstley Borate, then a mix of calcined and raw kaolin can be tuned to produce the right balance of suspension and dry hardness with good drying).

In porcelains, EPK fires whiter than most other North American kaolins. If whiteness is important consider substituting New Zealand or Grolleg kaolins. Switching for Grolleg will improve body whiteness somewhat. Depending on the percentage, New Zealand kaolin could make the body fire much whiter. Of course, these two kaolins are much more expensive. A practical approach is to substitute whichever kaolin you have and assess fired color and plasticity. If plasticity is lost just add a the amount of bentonite needed to restore it (e.g. 1-3%). If body workability is most important then #6 Tile kaolin is the right choice, it is the most plastic North American kaolin (actually, it might increase plasticity so much that the percentage of bentonite can be dropped).

In review: EPK is a secondary water-washed kaolin mined in Florida, USA. EPK, when wet, is sticky and thixotropic, for these reasons it is considered by many to be the best North American kaolin for use in suspending ceramic glazes. 15-20% will normally make the glaze gel slightly, thus when a piece is immersed in the slurry and removed it drips very little and the wet glaze layer stays in place for the time it takes to dewater. And it dries relatively hard. Since EPK is close to theoretical kaolin chemistry, it will substitute for any other such kaolins chemically (but not necessarily phyically). If the percentage is greater than 25% consider splitting it with calcined kaolin to prevent crawling.

EPK is whiter burning than other American kaolins, this is due to its relatively low iron content, but more importantly the low level of TiO2: 0.4 TiO2. While this is high compared to Grolleg and Super Standard Porcelain kaolins (about 0.05%), but other common American kaolins have multiple times more TiO2 than EPK!

EPK has excellent casting properties. But it is not plastic enough for throwing bodies, it must be augmented by a more plastic kaolin (like 6Tile) or by a plasticizer like bentonite, smectite or hectorite. Or, if whiteness can be sacrificed, by a ball clay.

This material is mined and processed in Edgar Florida. It is extracted hydraulically (a high-pressure stream of water is used to wash the clay/sand mix from the bank into a small lake). The slurry is pumped and transported to vibrating screens that separate out the sand and grade it into sizes. The clay that passes the screens is pumped into a pond and settled with the aid of a flocculant. The slurry is then dried and the flocculant neutralized. The main product at the mine is high-quality white sand, the clay is a byproduct. The company is confident that there are reserves for the next hundred years.

Related Information

What makes EP Kaolin unique? Are others as good?

This picture has its own page with more detail, click here to see it.

In ceramics, EPK, or EP Kaolin, is used in clay bodies and glazes. Top right: Pure EPK is fairly plastic on wedging. But during the throwing process, it splits at the rim like this. The forming properties that it does have thus seem to be as much related to its stickiness and cohesion as plasticity. Without the help of bentonite or ball clay this would not be able to host the addition of feldspar and silica to make a usable porcelain or stoneware. But EPK shines in what it does as a slurry. Left: This slurry has been mixed to only 1.15 specific gravity and forms a thixotropic gel that clings to the spatula in an even layer. Bottom: This low specific gravity gel is thick enough that it will hold this heavy spatula vertical! Considering that our typical glazes have a specific gravity of 1.45 yet are still quite fluid it is evident just how much EPK can gel (and suspend a suspension). It is thus no surprise that it is the kaolin of choice in ceramic glazes. Are there other sticky kaolins that gel like this? Yes. Grolleg and New Zealand kaolin.

EPK fired test bars, data, certificate and the data

This picture has its own page with more detail, click here to see it.

All of the test bars have been fired in this project to characterize a shipment of EPK (from cone 7-10 and 10R bottom to top). The dry and fired lengths and the dry and fired weights testdata was measured and entered into our Insight-live account. The results are shown in the red-titled columns (the drying shrinkage, firing shrinkage, absorption). The weights from the sieve analysis are also shown. And the calculation of water content of the plastic material (a very high 33.4%) and LOI (14.5%). We also like to take and upload a photo of the oversize material from the sieve analyses (to compare with past shipments) and of their manufacturers certificate of analysis.

Notice the data that the manufacturer considers important to include on the certificate that they send with the shipment: Particle size, particle surface area and moisture content. Of course, they would not be able to do all the tests we do. But our product is affected by the properties of the material, so we have to test.

#6 Tile Kaolin 2021 vs EP Kaolin 2020: Fired properties tell an unexpected story

This picture has its own page with more detail, click here to see it.

These test bars are fired at cone 10 reduction (top) and 10, 9 and 8 oxidation (downward) - they demonstrate the importance of measuring physical properties. The charts for each show data for drying shrinkage, firing shrinkage and porosity (water absorption). The left bars are #6 Tile kaolin and the right are EPK. These two kaolins had almost the same drying shrinkages in this SHAB test, that suggests the same plasticity. And the EPK fires whiter. So it should make a better plastic porcelain, right? Not so. In reality, #6 Tile kaolin is far more plastic - EPK requires the addition of significant bentonite to equal it (bentonite is dirty and that compromises whiteness). And EPK fires less vitreous - when feldspar is added color darkens. And, although both have extremely high firing shrinkages, the EPK is much higher than the #6 Tile (even though it is not as vitreous). Bottom line: #6 Tile is a better kaolin for clay bodies.

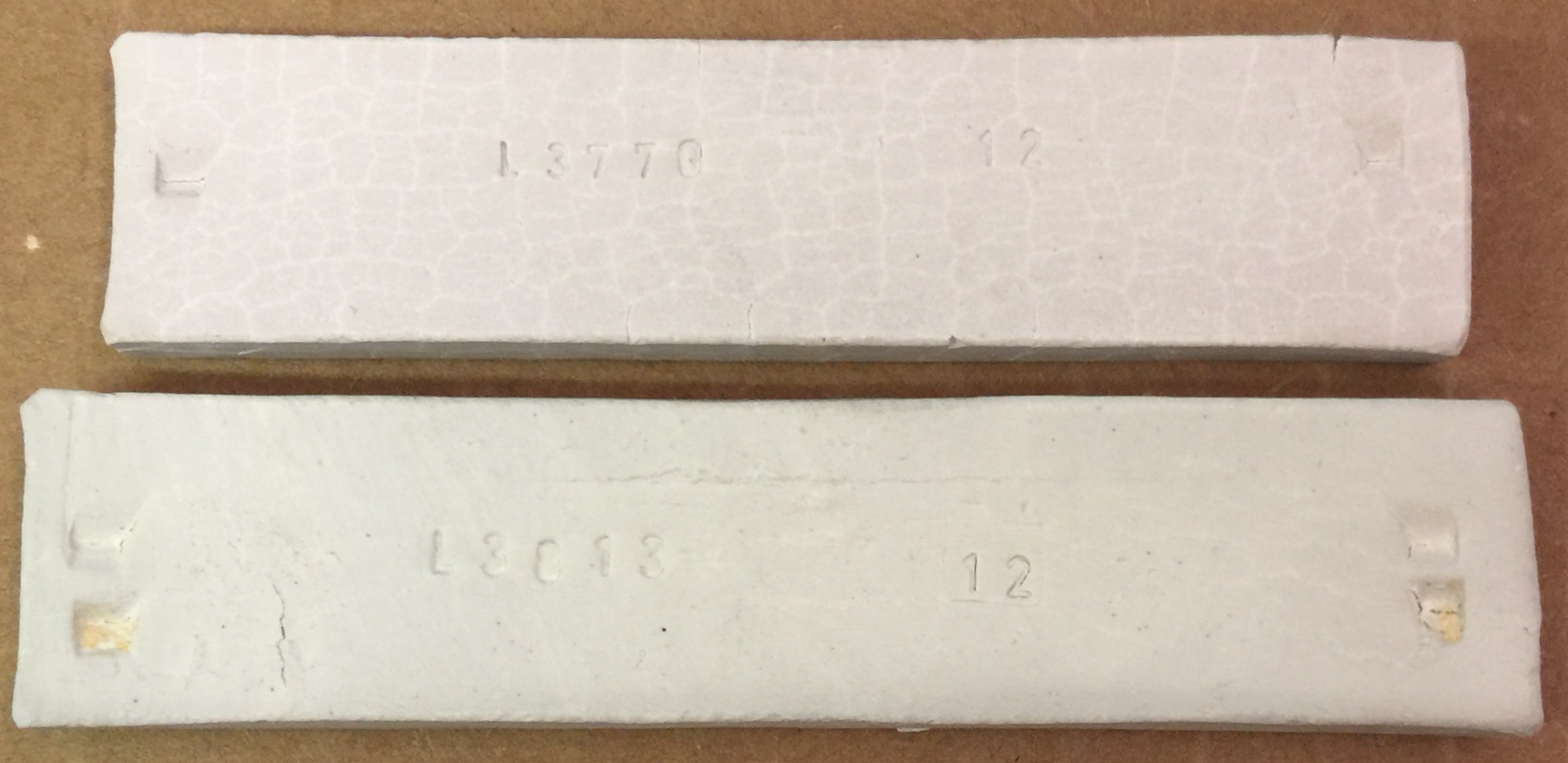

Two batches of EP Kaolin tested quite differently in 2018

This picture has its own page with more detail, click here to see it.

The EP kaolin has been mixed 70:30 with nepheline syenite. This creates a body that matures below cone 6. And it enables comparing the degree to which the two kaolins influence vitrification (and their contribution to fired color in a vitreous body). The darker one is more plastic, has higher drying shrinkage more soluble salts. These dry test bars were fired at cone 4-8 and had similar fired shrinkages and porosities. However, the one on the right fired whiter at all temperatures. These differences would impact the plasticity and drying shrinkage of bodies containing a significant percentage of the material. They would also influence the ability of this kaolin to suspend slurries.

EPK fired bar (top) vs Grolleg kaolin at cone 10R. Why shrinking more?

This picture has its own page with more detail, click here to see it.

From these SHAB test bars EP kaolin appears to have a much higher fired shrinkage. But half of that happened during drying. Still, EPK shrinks 4% more during firing. Yet Grolleg produces more vitrified porcelains. The EPK bar also appears to be whiter. Yet in a porcelain body, Grolleg fires whiter. That higher drying shrinkage proves that EPK is much more plastic, right? Not really. Throwing porcelains containing either require plasticity augmentation using similar percentages of bentonite. What do we learn? To compare materials like this we need to see them "playing on the team", in a recipe working with other materials. Don't rely on material data sheets, do the testing in your recipes.

A 70:30 mix of EPK:Nepheline Syenite has gone to mush

This picture has its own page with more detail, click here to see it.

This was plastic and moldable two days ago, now it is incredibly sticky. It is being compared with 5 other kaolin:nepheline mixes, none of them have reacted in this way. The material is sourced from two mines, the other mine does not do this.

Two kaolins, one cracks on bisque, the other does not

This picture has its own page with more detail, click here to see it.

Both of these are mixed 70:30 kaolin:feldspar. Left is a fine particled kaolin, #6 Tile. Right, a coarser particled, less plastic material, EPK. During forming, the larger particles of the latter line up concentrically to the center better. This causes the body to shrink more along radius lines than along tangents, producing these cracks (many were made and they all cracked like this). In addition, bodies employing kaolin as the only clay in the recipe often fail like this because they lack the “stress-relief plasticity” that a bentonite or ball clay addition provides. The Tile#6 material on the left contains natural bentonite, so it can better relieve drying stresses.

Thrown pieces made from pure Grolleg and EP kaolins

This is how you compare plasticities

This picture has its own page with more detail, click here to see it.

These have just been thrown on the wheel. I find it to be a foolproof method of comparing the plasticity of two clays. They were slurried up and dewatered to about the same moisture content and the same amount was thrown to compare the size achievable. While the Grolleg is stickier and dewaters a little slower, it is not nearly as plastic as EPK (which itself is not that plastic compared to others). Curiously, New Zealand kaolin (halloysite) is quite a bit less plastic than the Grolleg but it responds to plasticity augmentation (in porcelain recipes) just as well as Grolleg (similar amounts of bentonite producing similar plasticities). And, bodies containing EPK also need about the same amount of bentonite to produce plasticity suitable for throwing large forms. So, the plasticity that a kaolin appears to have by itself is not completely indicative of what it will contribute to a body (if augmented with bentonite). The EPK used here is the darker and more plastic of the two varieties Plainsman receives.

An effective test to judge the plasticity of a shipment of EP Kaolin

This picture has its own page with more detail, click here to see it.

This shipment of light EPK (there are two versions, light and dark) is just barely plastic enough to make this cylinder with a slight belly. Notice the splits on the rim, these are indicative of the shortness (low plasticity). The cohesiveness of the material, as much as plasticity, gives it a toughness to survive the stresses of throwing (an unique aspect of EPK).

Links

| Minerals |

Kaolinite

The most fundamental clay mineral. This mineral is found in nature in its purest form as kaolin. How |

| Materials |

Pioneer Kaolin

|

| Materials |

Edgar Glass Sand

|

| Materials |

Kaolin

The purest of all clays in nature. Kaolins are used in porcelains and stonewares to impart whiteness, in glazes to supply Al2O3 and to suspend slurries. |

| Typecodes |

Kaolin

Pure clay mineral, there are many brand names of varying purity and iron content. |

| Troubles |

Glaze Slurry is Difficult to Use or Settling

Understanding glaze slurry rheology is the key to solving problems and creating a suspension that does not settle out, applies well, dries crack free. |

| Glossary |

Thixotropy

Thixotropy is a property of ceramic slurries of high water content. Thixotropic suspensions flow when moving but gel after sitting (for a few moments more depending on application). This phenomenon is helpful in getting even, drip-free glaze coverage. |

| Projects |

Testing a New Load of EP Kaolin

Kaolins can vary in many ways. Yet they are the foundation of all porcelain and light stoneware clay body recipes. It is vital to test each incoming shipment of material. Problematic brands can even require some testing on every pallet. |

Data

| Pyrometric Cone Equivalent | 35 |

|---|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy