| Monthly Tech-Tip | No tracking! No ads! | |

Thick application clouds a transparent glaze on a terra cotta clay

Glaze clouding is a universal issue in ceramics. Terra cotta bodies demonstrate this best. Pretty well all transparent glazes, even commercially available ones, can cloud. This example is G2931K, it can be beautifully crystal clear. But the thickness of application is the key to achieving that (as thickness increases this happens). We ball milled it to see if that would help, but as you can see, that has not impacted the problem. This is a dipping version so that is part of the reason why it is easy to get it on too thick. One of the advantages of brushing glazes is the ability to carefully control thickness,

.

Related Pictures

The outside glaze has a fining agent that clears the bubble clouds

This picture has its own page with more detail, click here to see it.

This is a buff stoneware body, Plainsman M340. A L3954F black engobe was applied inside and upper outside at leather hard. The piece was fired at cone 6 using the PLC6DS schedule. The inside, totally clouded glaze, is G2926B. Outside is GA6-B Alberta Slip amber transparent. Normally, this inside glaze is crystal-clear on other bodies (and on this one without the black engobe). Clearly, the black stain in the engobe is generating tiny gas bubbles at the exact wrong time during the firing and the melt is unable to pass them. The outside glaze is on the same engobe, but the GA6-B glaze is demonstrating its ability to clear the micro-bubble clouding. It contains a lot of Alberta Slip, a material that is not finely ground like others. Particles across the range from 60-200 mesh are present, some of them appear to be acting as a fining agent to clear the bubbles.

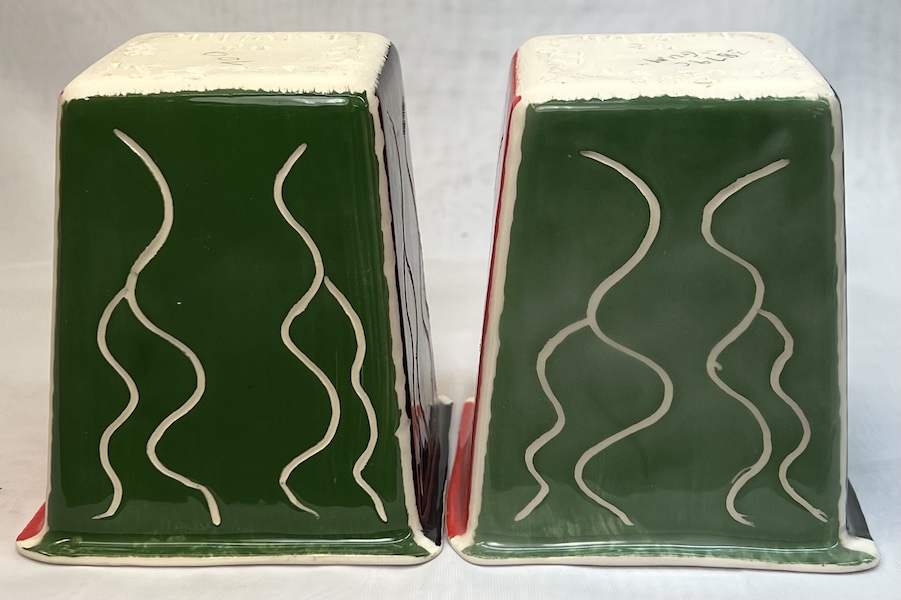

Transparent glaze thickness really matters over this Amaco velvet underglaze

This picture has its own page with more detail, click here to see it.

At the leather hard stage the sides of these two L4410P low temperature dolomite body pieces were coated with AMACO velvet underglazes. Both were bisque fired and finished with a layer with the same transparent glaze. But the difference is the thickness of that glaze and the method of application: The one on the left got three thin layers of a brushing glaze. The one on the right was quickly dipped in a base coat version of that same glaze. Evidently there is a thickness threshold, which, when exceeded results in clouding. We have observed that this happens with pretty well any clear glaze.

Transparent glazes often work poorly on dark stoneware bodies

This picture has its own page with more detail, click here to see it.

These are fired in cone 6 oxidation. They are all the same clay body (Plainsman M390). The center mug is clear-glazed with G2926B (and is full of bubble clouds). This dark body is exposed inside and out (the other two mugs have L3954B white engobe inside and midway down the outside). G2926B clear glaze is an early-melter (starting around cone 02) so it is susceptible to dark-burning bodies that generate more gases of decomposition - they produce the micro-bubble clouding. That being said, the other two glazes here are also early melters - yet they did not bubble. Left: G2926B plus 4% iron oxide. That turns it into an amber color but the iron particles act as a fining agent (vacuuming up the bubbles)! Right: Alberta Slip GA6-B. It also fires as an amber-coloured glass, but on a dark body, this is an asset.

Lead bisilicate with his ugly borosilicate cousins at a cone 05 party

This picture has its own page with more detail, click here to see it.

The middle front mug is glazed with an 85:15 lead bisilicate:kaolin mix, the G3971 recipe. It is an absolutely "knock your socks off" crystal-clear hyper-glossy surface that transmits the terra cotta color beautifully regardless of whether the clay is smooth or coarse or the glaze thick or thin (this one was applied as a brushing glaze in three coats on L215). My lead testing kit passes it with no detectable lead release. The other pieces are done using brush-on versions of boron-based clear glazes (commercial and made from a recipe). At almost any thickness and whether on L215 or L4170B clouding occurs. The worst one is a commercial three-coater on the right, the best is G1916W (it has 2% added iron as a fining agent for the micro-bubbles). My terra cotta plan: Glaze the inside functional surfaces with that and the outsides with the leaded one (and using a kiln exhaust system).

Videos

Links

| Troubles |

Clouding in Ceramic Glazes

There a many factors to deal with in your ceramic process to achieve transparent glazes that actually fire to a crystal-clear glass |

| Glossary |

Glaze thickness

Many ceramic glaze benefits and issues are closely related to the thickness with which the glaze is applied. Many glazes are very sensitive to thickness, so control is needed. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy