| Monthly Tech-Tip | No tracking! No ads! | |

Black ash glaze for 20% raw metal pigments: Suitable for functional ware?

This glaze is 49% Wood Ash, 24% Soda Feldspar and 27% Ball Clay. 10 copper carbonate and 10 manganese dioxide are added to that. This beautiful sculpture was made by Dan Ingersoll, aesthetically this glaze is perfect for it. But there are two red flags here. Significant manganese and copper metal fumes are certain to be generated at cone 10 (they are seriously not healthy) so anyone using this must be very careful. But there is something much more serious - this glaze is being used on functional ware. Copper is well known to destabilize other metals in the fired glass. This 10:10 combination is a perfect storm for leaching heavy metal into food and drink. This is not an argument for the use of commercial glazes, it is one for common sense application of the concept of limit recipes.

Related Pictures

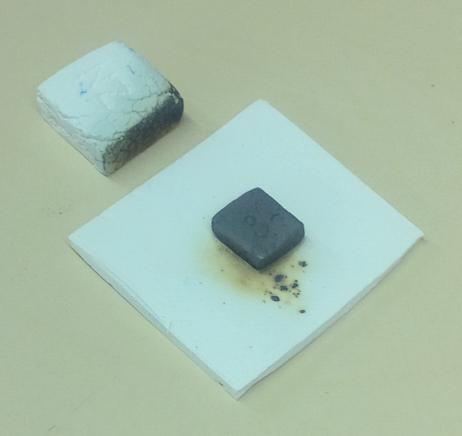

Copper carbonate fuming

This picture has its own page with more detail, click here to see it.

And example of how copper carbonate fumes during firing. The white sample on the left was near the copper sample, at around 1500F the fumes discolored its facing edge. These are permanent, they do not fire out but get darker with increasing temperature (this is 1950F). The kiln shelf was also discolored outward about half an inch from the copper specimen.

Videos

Links

| Hazards |

Manganese Inorganic Compounds Toxicology

|

| Hazards |

Copper Oxide and Carbonate

|

| Hazards |

Copper Compounds Toxicology

|

| Materials |

Manganese Dioxide

A source of MnO used in ceramic glazes and the production of ceramic stains. Commonly made by grinding pyrolusite rock. |

| Materials |

Copper Carbonate Basic

This form of copper carbonate is the article of commerce, a mixture of theoretical copper carbonate and copper hydroxide. |

| Articles |

Are Your Glazes Food Safe or are They Leachable?

Many potters do not think about leaching, but times are changing. What is the chemistry of stability? There are simple ways to check for leaching, and fix crazing. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy