| Monthly Tech-Tip | No tracking! No ads! | |

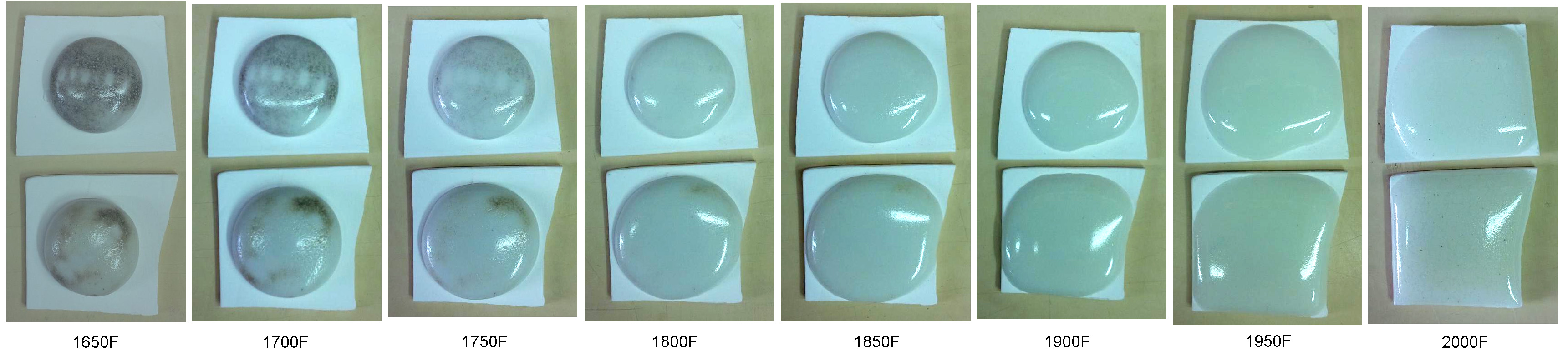

Melting glaze balls at various temperatures to see when all carbon has been expelled

G1916Q and J low fire ultra-clear glazes (contain Ferro Frit 3195, 3110 and clay) fired across the range of 1650 to 2000F (these were 10 gram GBMF test balls that melted and flattened as they fired). Notice how they soften over a wide range, starting below cone 010 (1700F)! At the early stages carbon material is still visible (even though the glaze has lost 2% of its weight to this point), it is likely the source of the micro-bubbles that completely opacify the matrix even at 1950F (cone 04). This is an 85% fritted glaze, yet it still has carbon - think of what a raw glaze might have! Of course, these specimens test a very thick layer, so the bubbles are expected. But they still can be an issue, even in a thin glaze layer on a piece of ware. So to get the most transparent possible result it is wise to fire tests to find the point where the glaze starts to soften (in this case 1450F), then soak the kiln just below that (on the way up) to fire away as much of the carbon as possible. Of course, the glaze must have a low enough surface tension to release the bubbles, that is a separate issue.

Videos

Links

| Glossary |

LOI

Loss on Ignition is a number that appears on the data sheets of ceramic materials. It refers to the amount of weight the material loses as it decomposes to release water vapor and various gases during firing. |

| Glossary |

Glaze Bubbles

Suspended micro-bubbles in ceramic glazes affect their transparency and depth. Sometimes they add to to aesthetics. Often not. What causes them and what to do to remove them. |

| Glossary |

Transparent Glazes

Every glossy ceramic glaze is actually a base transparent with added opacifiers and colorants. So understand how to make a good transparent, then build other glazes on it. |

| Glossary |

Soaking

The process of holding a kiln at the final temperature (or at other temperatures) to enable the heat to penetrate the ware or to effect or complete a glaze or body reaction |

| Materials |

Ferro Frit 3110

High sodium, high thermal expansion low boron frit. A super-feldspar in clay bodies. Melts a very low temperatures. |

| Materials |

Ferro Frit 3195

A commonly used boron frit, it is a balanced glaze all along at cone 06-02 (with the addition of 10-15% kaolin). Not fully glossy. |

| Tests |

Glaze Melt Fluidity - Ball Test

A test where a 10-gram ball of dried glaze is fired on a porcelain tile to study its melt flow, surface character, bubble retention and surface tension. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy