| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

PC-20 floating blue with two alternatives you can make yourself

These are GA6-C Alberta Slip floating blue (left), AMACO Potter's Choice PC-20 Blue Rutile (center), GR6-M Ravenscrag floating blue (right). The clay is M390. The firing is cone 6, the schedule is C6DHSC (drop-and-hold, slow cool). All of these recipes are descendants and improvements of the 50-year-old original G2826R floating blue. The inside glaze on these mugs is GA6-B. The two on the left develop the blue color because of the slow cool, the one on the right works on fast-cool (because it contains cobalt). Remember, floating blue is a rutile blue glaze, as such it works best on dark-burning bodies.

Related Pictures

Ravenscrag cone 6 floating blue thinner and thicker applications

This picture has its own page with more detail, click here to see it.

The body is red-burning Plainsman M390. The firing was dropped and soaked at 2100F for 30 minutes and then dropped at 300F/hr to 1400F. This really helps to produce a dazzling defect-free surface in the GR6-M glaze. These are, of course, mix-your-own recipes and the pieces were dipped to get even coverage.

Ravenscrag Cone 6 Floating Blue on porcelain and a red stoneware

This picture has its own page with more detail, click here to see it.

The insides are GA6-A Alberta Slip cone 6 base. Outsides are Ravenscrag Floating Blue GR6-M. The firing was soaked at cone 6, dropped 100F, soaked again for half and hour then cooled at 108F/hr until 1400F. The speckles on the porcelain blue glaze are due to agglomerated cobalt oxide (done by mixing cobalt with a little bentonite, drying and pulverizing it into approx 20 mesh size and then adding that to the glaze slurry).

G2917 Ravenscrag floating blue as a dipping and brushing glaze at cone 6

This picture has its own page with more detail, click here to see it.

The dipping glaze version of G2917 was used on the left, we make that by the bucket and it drains and dries in seconds after dipping bisque ware. We also make a brushing glaze version in our studio (it is not sold). That was used on the outside of the mug on the right. Of course, it is much slower to apply but there are some advantages. First, it was easy to control the thickness to maximize the variegation this glaze gives with thin and thick, revealing the throwing lines better. And where thicker application was needed (e.g. at the rim) it was easier to achieve that. Near the foot ring, it has been applied in a thinner layer. And the brush strokes do impart a more handmade look that is also nice.

Titanium instead of rutile for floating blue

This picture has its own page with more detail, click here to see it.

Rutile blue glazes are actually titanium blues (because rutile mineral is an impure source of TiO2 and Fe2O3). The iron and titanium in the rutile react to form the floating blue effect. The GA6-C recipe has always relied on a 4% rutile addition. Its GA6-A base recipe contains significant iron (because of the 80% Alberta Slip), so could titanium oxide deliver the same floating blue effect? Yes.

These mugs are M390 clay. The top left one is the standard GA6-C (with rutile) fired using the C6DHSC slow-cool firing schedule (the bottom left normal cool PLC6DS schedule produces little color). But the ones on the right switch the 4% rutile for titanium dioxide (the L4655 recipe). The top right was fired using the slow cool, the bottom right was the normal cool schedule.

Titanium thus seems more consistent and reliable material than rutile. An excellent blue color is produced even without a slow cool (lower right).

Recognize these universal oxidation glazes?

Almost every potter needs a Albany brown and rutile blue.

This picture has its own page with more detail, click here to see it.

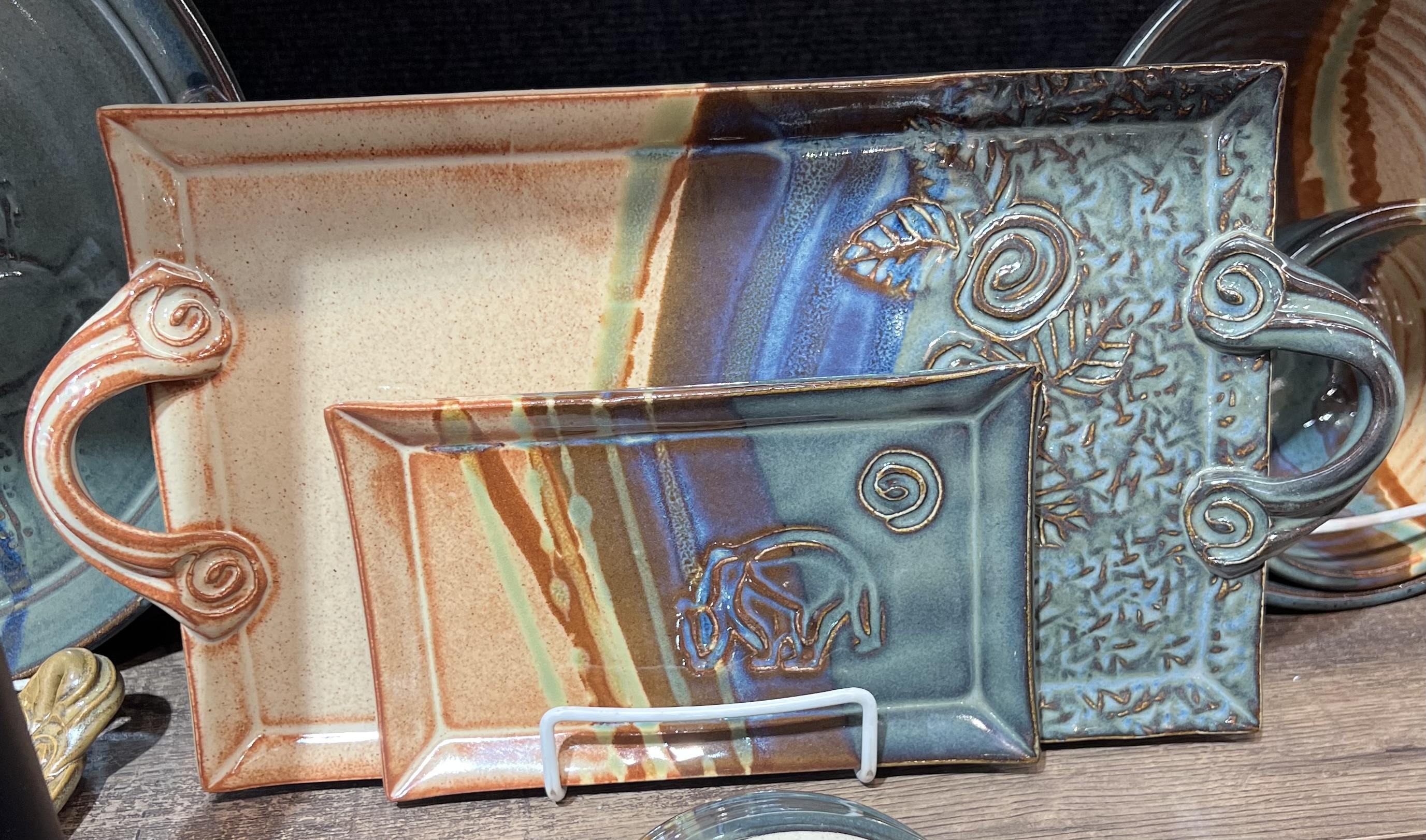

These are made by Barbara Childs Pottery (I saw them on sale in a tourist shop in Alaska). To keep costs down, I first assumed they use dipping glazes they mix themselves. Potter's Choice PC-32 Albany Slip Brown and PC-20 Rutile Blue hobby glazes emulate these long time pottery glaze recipes. However, a reader noted that Barabara Childs uses Clay Art Center’s Stellar Rust and Floating Blue (with guest appearances by Blue Green). But Amaco and Clay Art don't just use the traditional recipes; they adapt and improve them. Consider the rutile blue. Neither is using the traditional G2826R floating blue recipe, there are new and better ways using recipes like GA6-C and GR6-M. Likewise, with the brown, they are not using the traditional G2415E Albany Brown recipe. Rather, they improve it (e.g. like we did with G3933G1). High on their list of improvements would have been a way to reduce or remove the lithium to cut costs. Maybe you are a hobbyist and don’t feel you need to DIY your costs down. But do your customers feel the same way? Not buying just ten small jars of hobby brushing glaze will pay for a mixer and much of the ingredients to make gallons of each of these as dipping glazes. It will also set you on the road to gradually improving the glazes you use. And even reducing your prices. What about buying premixed powders? Yes, that is much less expensive. But if you are mixing the glaze from one manufacturer with the clay body from another, crazing is an ever-present issue. Mixing your own enables an adjustment to fix the problem.

Videos

Links

| URLs |

https://insight-live.com/insight/share.php?z=oLZXQTy9TR

Floating Blue - Substituting Gerstley Borate The original floating blue recipe shown side-by-side with variations made using frits instead of Gerstley Borate (and titanium and iron instead of rutile). |

| Typecodes |

Floating Blue

A popular cone 6 glaze that employed Gerstley Borate, it was very troublesome to use and to fire. Much work has been done to create alternative recipes. |

| Glossary |

Rutile Blue Glazes

A type of ceramic glaze in which the surface variegates and crystallizes on cooling in the presence of titanium and iron (usually sourced by rutile) |

| Materials |

Ceramic Rutile

Rutile mineral ground to a very fine particle size (e.g. 325 mesh) contributes titanium and iron that colors and variegates ceramic glazes. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy