| Monthly Tech-Tip | No tracking! No ads! |

This is crazing. On functional ware. No good.

This glaze is "stretched" on the clay so it cracks. When the lines are close together like this it is more serious. If the effect is intended, it is called "crackle" (but no one should intend this on functional ware). Potters, hobbyists and artists invariably bump into this issue whether using commercial glazes or making their own.

"Art language" solutions don't work, at least some technical words are needed to understand it. Crazing is a mismatch in the thermal expansions of glaze and body. Most ceramics expand slightly on heating and contract on cooling. The amount of change is very small, but ceramics are brittle and glazes are rigidly attached. If they are stretched on the ware cracks will occur to relieve the stress (usually during cooling in the firing but sometimes much later). All glaze and body manufacturers advise against crazing on functional ware.

AI generated with the prompt: A crazed glaze on a stoneware pottery mug.

Related Pictures

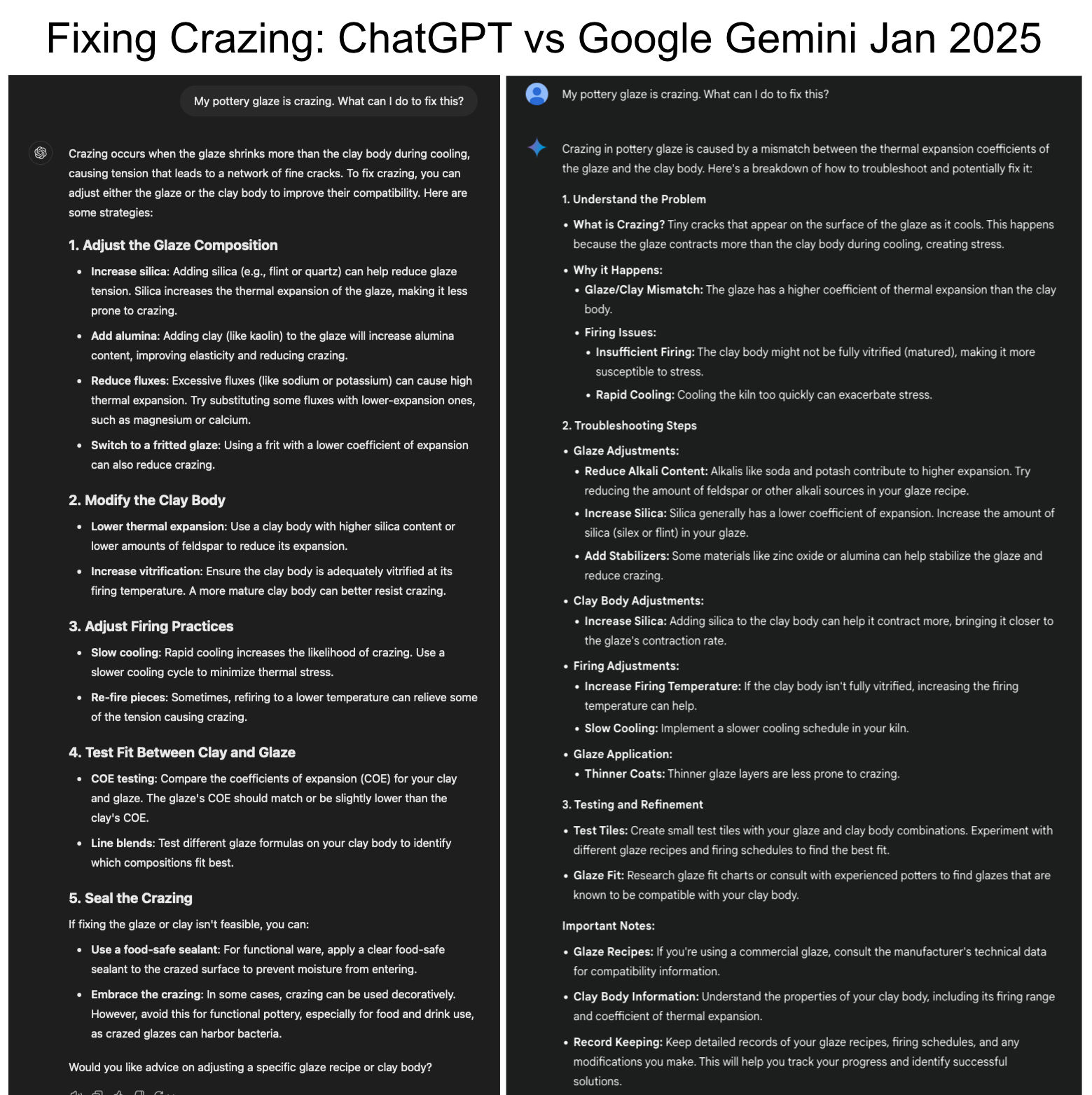

Two ChatBots square off on crazing in 2025

This picture has its own page with more detail, click here to see it.

In 2025 ChatGPT’s four glaze adjustment suggestions are either wrong or will accidentally fix crazing because they address other issues that just happen to also be present. Adding enough silica or alumina brings unacceptable side effects on multiple fronts. Alkali fluxes need to be substituted, not reduced. Simply substituting frits changes the overall chemistry making it a different glaze - why not just use a recommended recipe for the body as suggested by Gemini? Adding silica to a body increases, not decreases, the thermal expansion (and it reduces vitrification). Increased vitrification doesn’t make the body resist crazing (bodies don’t craze) - unless increased vitrification happens to also increase the thermal expansion (but not introduce warping). Slower cooling or a lower refire only delays crazing. Comparing COE’s of body and glaze is impossible for anyone not having a dilatometer to test both (you cannot compare measured and calculated COEs and calculation of COE for bodies is impossible). Embracing the crazing is a no-go for functional ware.

Gemini correctly explains why it happens. But, it suffers similar misconceptions about vitrification, cooling, silica additions to the body, vitrification and ignores the side effects of increasing silica or alumina in a glaze recipe. It is right that alkalis need reduction, but fails to note what to substitute. It recommends zinc as a stabilizer (whatever that means), but zinc is a strong flux that should be substituted for KNaO. Thinner glaze coating just delays crazing. Its suggestions about experimenting, keeping records, and researching to find recipes known to be compatible with the body are good. The only information available from glaze or body suppliers that might help is a chart that permits ordering products from lowest to highest COE (enabling you to at least transition in the right direction for better fit).

Two matte mechanisms: One crazes, the other does not

This picture has its own page with more detail, click here to see it.

These two glazes look the same, they are both cone 6 satin mattes. On the same porcelain. But the matteness "mechanism" of the one on the left, VC71, is a low Si:Al ratio melted by zinc and sodium. The mechanism of the one on the right, G2934, is high MgO melted by enough boron to also have plenty of SiO2 and Al2O3. The "baggage" of the mechanism on the left is high thermal expansion and crazing (drastically reducing strength and providing a space for a germ zoo). If your ware develops this your customers will bring it back for replacement. No change in firing will fix this, the body and glaze are not expansion compatible. Period.

Videos

Links

| URLs |

https://ceramicartsnetwork.org/ceramics-monthly/ceramics-monthly-article/Techno-File-Dirty-Dishes#

Bacterial survival studies done on crazed glazes had surprising results. But also oversights. This article, Techno File: Dirty Dishes, argues that the dangers presented by microbes on crazed glazes are over-blown and unwarranted. And that pores and surface irregularities in even uncrazed glazes could also harbour bacteria if surfaces are not cleaned. But, it fails to address a number of factors. -The possible presence of a porous body below (that could harbour pathogens). -Regulatory bodies regard it as a compromise of the integrity of the glaze and the ability to clean the surface properly. -A dramatic reduction in ware strength accompanies crazing. -No commercial hobby glaze manufacturer recommends the use of crazed glazes on food surfaces. -That it is usually easy to fix. |

| Troubles |

Glaze Crazing

Ask the right questions to analyse the real cause of glaze crazing. Do not just treat the symptoms, the real cause is thermal expansion mismatch with the body. |

| Glossary |

Glaze Crazing

Crazed ceramic glazes have a network of cracks. Understanding the causes is the most practical way to solve it. 95% of the time the solution is to adjust the thermal expansion of the glaze. |

| Glossary |

Glaze Chemistry

Glaze chemistry is the study of how the oxide chemistry of glazes relate to the way they fire. It accounts for color, surface, hardness, texture, melting temperature, thermal expansion, etc. |

| Articles |

Where do I start in understanding glazes?

Break your addiction to online recipes that don't work or bottled expensive glazes that you could DIY. Learn why glazes fire as they do. Why each material is used. How to create perfect dipping and brushing properties. Even some chemistry. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy