| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

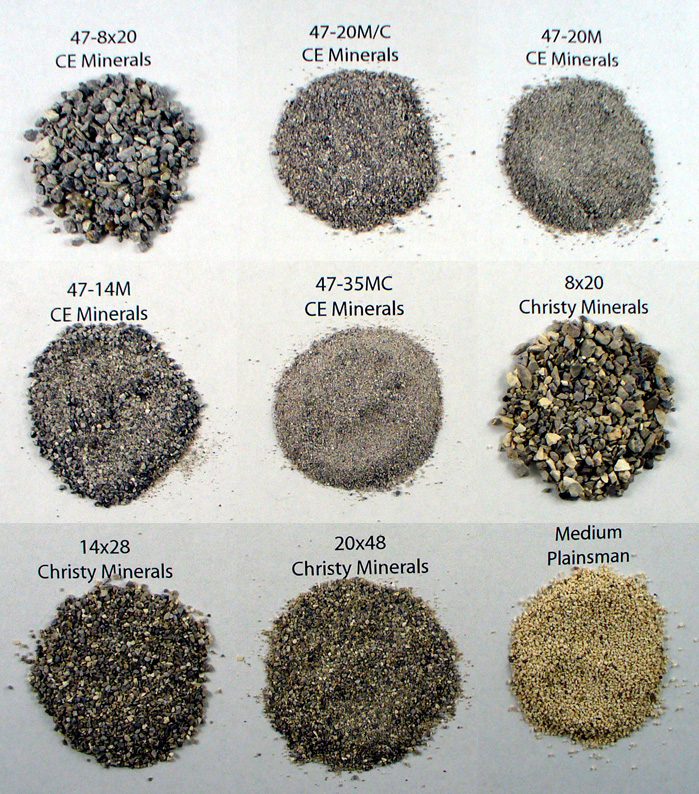

Various grogs available in North America

Examples of various sized grogs from CE Minerals, Christy Minerals, Plainsman Clays. Grogs are added to clays, especially those used for sculpture, hand building and industrial products like brick and pipe (to improve drying properties). The grog reduces the drying shrinkage and individual particles terminate micro-cracks as they develop (larger grogs are more effective at the latter, smaller at the former). Grogs having a narrower range of particle sizes (vs. ones with a wide range of sizes) are often the most effective additions. Grogs having a thermal expansion close to that of the fired body, a low porosity, lighter color and minimal iron contamination are the most sought after (and the most expensive).

Videos

Links

| Materials |

Grog

|

| Materials |

Christy Minerals STKO 22 S Grog

|

| Glossary |

Drying Performance

In ceramics, drying performance is very important to optimizing production. More plastic clays shrink more and crack more, but they are also better to work with. |

| Glossary |

Drying Crack

During drying clays and porcelains shrink as they become rigid. When this occurs unevenly, cracks are the result. |

| Glossary |

Sculpture

In ceramics, clays with added aggregate are free formed or molding into shapes that are slowly dried and fired in a kiln. The process requires much skill. |

| Glossary |

Grog

Grog is a term used in ceramics to describe crushed brick (or other fired ceramic) aggregate that is added to sculpture and structural clays to improve drying properties. |

| Glossary |

Drying Shrinkage

Clays used in ceramics shrink when they dry because of particle packing that occurs as inter-particle water evaporates. Excessive or uneven shrinkage causes cracks. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy