Notes

Christy Minerals describes this as "A calcined fireclay with high refractoriness, low alkalis and iron, and a low cristobalite content. This material is ideally suited to the refractory industry for manufacturing bricks, castable, and plastic. It is also used in the pottery and terra cotta industries as a grog in a variety of body formulations."

Many sizes are available (see linked data sheet). This is targetted at investment casting, it is screened to close tolerances to assure consistent, precise sizing. De-dusting throughout the screening process makes it virtually dust-free.

The MCF designation refers to Missouri Calcined Fireclay. The company sells the raw fireclay and many calcined products made from it.

Related Information

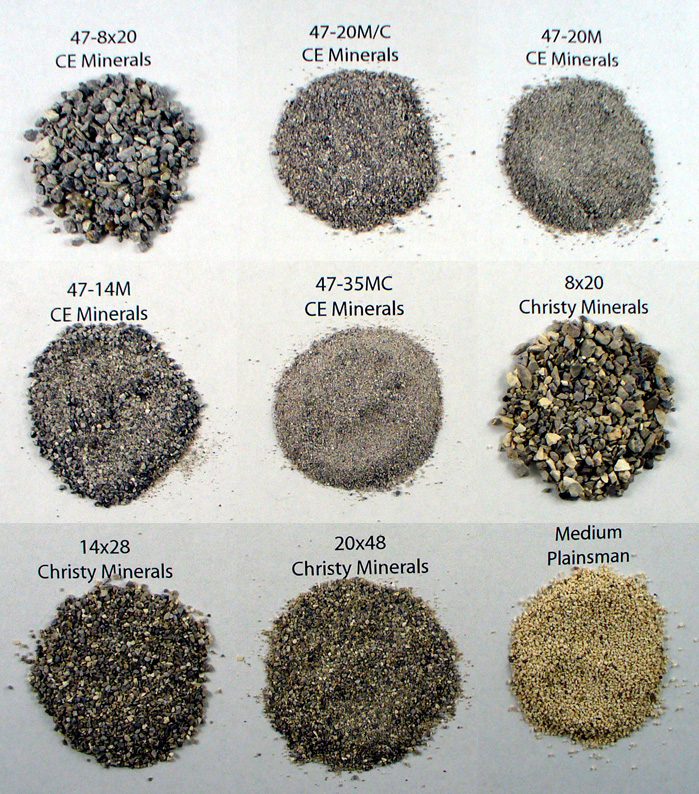

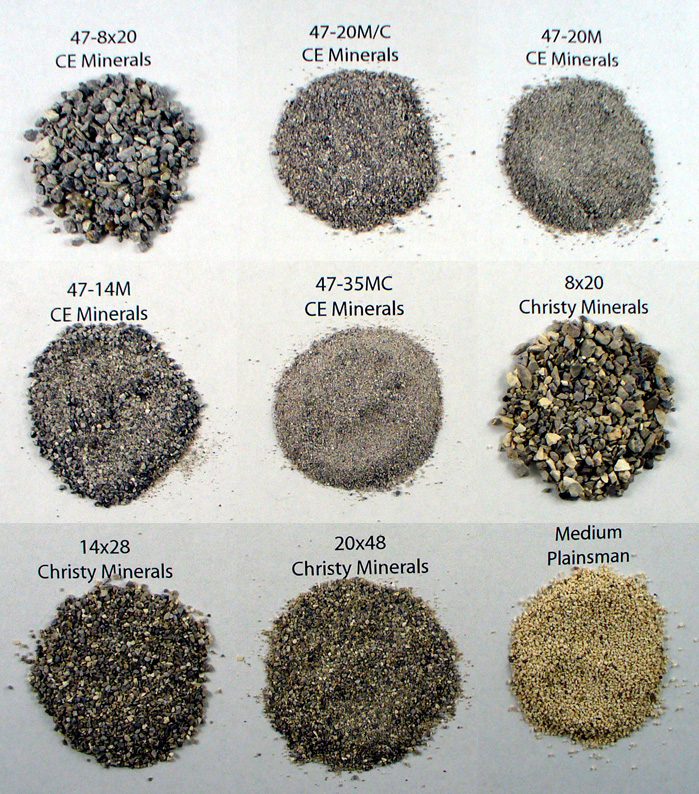

Various grogs available in North America

This picture has its own page with more detail, click here to see it.

Examples of various sized grogs from CE Minerals, Christy Minerals, Plainsman Clays. Grogs are added to clays, especially those used for sculpture, hand building and industrial products like brick and pipe (to improve drying properties). The grog reduces the drying shrinkage and individual particles terminate micro-cracks as they develop (larger grogs are more effective at the latter, smaller at the former). Grogs having a narrower range of particle sizes (vs. ones with a wide range of sizes) are often the most effective additions. Grogs having a thermal expansion close to that of the fired body, a low porosity, lighter color and minimal iron contamination are the most sought after (and the most expensive).

Plainsman M390 plus 12.5% Christie STKO 22S grog

This picture has its own page with more detail, click here to see it.

This is the surface after trimming. M390 is normally smooth. It is plastic enough to be able to tolerate this grog without apparent loss in workability (still throwing well). And it does not feel overly abrasive on the wheel (unless your hand goes down onto the wheelhead). How is that possible? Although the particles of grog are large, they are not touching each other and readily press down into the clay.

Adding 10% STKO 22 S grog to a smooth stoneware does this

This picture has its own page with more detail, click here to see it.

This is Plainsman M350. A freshly trimmed foot and the same piece after firing at cone 6. Although this amount of grog is enough to make this body impractical for throwing it is not enough to significantly reduce the drying shrinkage (it dropped by at 0.5%). However, it does speed up drying, providing more channels for water exit. This body has very high dry strength, that alone eliminates a lot of drying cracks that would otherwise occur.

STKO grog original container bags

This picture has its own page with more detail, click here to see it.

Links