| Monthly Tech-Tip | Feb 14-15, 2026 - Major Server Upgrade Done | No tracking! No ads! |

Pugmill

The practice of removing air from clay as it is pugged. Deaired clay has better forming properties and produces a smoother fired surface.

Key phrases linking here: de-airing pugmill, pugmill - Learn more

Details

Pugmills have a main chamber with rotating shaft having angled blades. The shaft is rotated by powerful motor, turning slowly (about once every 3 seconds). The blades cut through and mix and push the clay mass slowly along the chamber. Typically the main chamber feeds into an auger that compresses the mass and forces it through a shredder into a secondary chamber, usually having vacuum. The vacuum chamber also has blades that continue cutting and exposing as much surface as possible (for air removal). Finally the clay is augered into the nozzle which feeds the die that controls the shape extruded. Very high pressures within the nozzle and die help knit together the mass to produce maximum possible density.

Prevailing knowledge and opinion is that deaired clay normally has better forming properties and produces a smoother fired surface than that prepared by other methods. This is especially true for bodies of lower plasticity or of certain formulations (e.g. high silt, high talc). However for most plastic terra cottas, stonewares and porcelains; slurrying, dewatering and wedging produce similar workability.

Traditions in many places are to age clay after pugging to improve plasticity. This may be worth the effort for non-plastic bodies but for plastic ones (e.g. those used on a potter's wheel to make large ware), the clay is typically fine right out of the nozzle of the machine. Today, low plasticity is normally managed by a simple bentonite addition or substitution of kaolin for ball clay.

Pugmills can be a part of a larger mixed process or it can be the only one. Theoretically, the ideal is a slurry mixing process to thoroughly blend the materials and wet all particle surfaces (called blunging). The blunger then feeds a screening device that removes coarser particles. That in turn feeds a filter press that dewaters the slip. Flat filter cakes produced by the press are then fed into a premixer that re-blends the separated layers in the cakes. The premixer then feeds the pugmill and it finalizes mixing and de-airs and extrudes the material. However, the more plastic the clay, the less practical some of the steps in the above process are. This is because highly plastic bodies do not screen well, they do not filter press well and they stick inside the premixer. If a de-airing pugmill has enough blades, they are angled for the best mixing possible (rather than speed), the dry material and water can be fed directly into the head of the main pugmill chamber the pugmill can do all of the above steps by itself! In fact, for superplastic bodies, there is not really another practical method.

Industrial heavy-duty pugmills. The die (bottom left) can do eight side-by-side extrusions!

Studio potters often use de-airing pugmills to re-pug incoming material and to reprocess production scrap. Very capable small pugmills are commonly available and potters highly value them.

Related Information

Deairing mixer pugmill at Plainsman Clays

This picture has its own page with more detail, click here to see it.

The pugmill has been reassembled after cleaning and is ready for startup. This machine is powerful and capable of injecting a lot of energy into the material, enough that a premixer is not needed for typical body types. Clay powder and water are fed into the main mixing chamber by a screw conveyor at the far end. Dozens of blades on the rotating shaft inside cut and mix the material with the water so that by the time it has reached halfway all traces of powder are gone. At the end of the main chamber an auger delivers the soft clay to a narrowing venturi terminated by a shredder. This compresses and slices the material with dozens of tiny blades as it enters the vacuum chamber (yellow cover). This chamber, into which the main shaft extends, contains many more blades that further mix and expose as much surface as possible for de-airing. The material proceeds to a final auger that further compresses the clay and delivers it to the nose where a column is extruded for cutting to length and packaging. This combination premixing and pugging in the same machine enables a continuous process from raw lumps to powderizing to final pugged product.

A compressing pugmill die with higly polished inside surface

This picture has its own page with more detail, click here to see it.

A quality extrusion depends a lot on the design of the nose of a pugmill. On this industrial pugmill at Plainsman Clays this is the custom design it took to prevent laminations and peeling at the edge of extrusions, especially on lower plasticity clay bodies. This nose assembly weighs about 70lb. It is fed by a long auger from a vacuum chamber. This design achieves compression by easing the extrusion outwards and then abruptly narrowing it.

Pugmill cleanup in preparation for making a porcelain

This picture has its own page with more detail, click here to see it.

The machine is being cleaned in preparation for a porcelain run (after producing stoneware clays). The pugmill has been stripped down completely - all parts in the main chamber, vacuum chamber and in the nose). The casings, augers and other components are washed, dried and inspected. Clean-downs and associated maintenance like this are costly but necessary to ensure quality porcelain. Each time we do this we are reminded how amazing this machine is - it can premix, pug and de-air even the most difficult of all clay bodies, Polar Ice. That body can be thrown straight out of the machine as plastic as it would be if aged for a year. This machine routinely produces 600+ boxes per day, turning powder into pugged in a continuous operation.

Wear on augers that occurs when pugging grogged clays

This picture has its own page with more detail, click here to see it.

Augers like these force the clay into the nose of the pugmill for extrusion. The one on the left was originally the same size as the one on the right. But the wear of grog particles in the clay have worn it down. Particles of quartz also take their toll on pugmills.

Wear that occurs on the stainless steel shaft casing of a pugmill

This picture has its own page with more detail, click here to see it.

Clay is soft, but when under pressure in the nose and shredder feeders the abrasive particles within it (grog and quartz) take their toll.

Studio pugmills have come a long way

This picture has its own page with more detail, click here to see it.

The same pugmill (back and front). One is stainless steel. Potters claim that they can dump almost anything into these machines (even dry scrap) and as long as they add the right amount of water the devices will mix and vacuum extrude a finished slug. Considering how portable these are they are an amazing device. However, these are no match for a large industrial pugmill. In the quantity of material they can produce, but also in the quality. They have few or even no blades on the main shaft, only augers. They contain no or only a rudimentary shredder feeding the vacuum chamber and little dwell time in the both chambers.

Pugmills used in hobby and industry are very different

This picture has its own page with more detail, click here to see it.

Example request-for-bid for an alumina extrusion pugmill, much more demanding, technical and specialized than a pottery pugmill (like that shown here). Alumina and cordierite extruders much work at very high pressures and shear much more.

-Purpose: De-air and extrude pure alumina (having 15-20% water and 2-4% methyl cellulose or HPMC binder).

-Type: Twin-screw feed (counter-rotating) horizontal.

-Capacity: 35-50Kg per hour.

-Barrel dia: 80mm.

-Screw RPM: 1-36 (adjustable).

-Extrusion pressure: 150-200 bar.

-Vacuum capability: 50 mbar.

-Cooling System for screw and barrel: Water cooling to maintain 10°C – 30°C during extrusion.

-Sensor system: Display of operational parameters like pressure, speed, torque, temperature etc.

-Cleaning of screw and barrel: Self-cleaning function/design.

-Coating thickness on auger and barrel: Alumina coated with 1500–2000 um thickness having excellent adhesion and wear resistance.

-Design: Specifically designed/configured, with conveyor, to extrude profiles like rod, tube, column etc. up to dia. of 70 mm.

-Spares: Two extra complete compatible augers.

Clay is tearing out of the pugmill die? Why?

This picture has its own page with more detail, click here to see it.

At first it appeared to be the lack of a tapered die. Two were designed. The first did not solve the problem (right). Although it was tapered, it was only 5/8" thick (left overlay on the bottom right). Before going to a longer tapered die (bottom right overlay) we did a rethink. The clay being fed into this pugmill has already been processed in an industrial pugmill having 40 blades in the main chamber, a compression auger to a very efficient shredder, a vacuum chamber with about 20 more blades and another auger feeding a very long nose with dual compression dies. And a very powerful motor to drive the clay out the nose. The small pugmill here only has one shaft with few auger-like blades in the two chambers. A "screen" shreds the clay on the way into the vacuum. Each time the clay goes through the screen could its cohesiveness actually be compromised more by not being knitted back together properly in the nose? That could have been solved by the longer gently tapered die. But, it would not likely have worked, the clay would simply back-feed into the vacuum chamber because the design and power would not be sufficient to push it out the die. In the end the problem was fixed, but no how you might think: They turned off the vacuum!

Laminations in pugged clay: Wedge it or lose the ware

This picture has its own page with more detail, click here to see it.

These are cross-cuts from slugs of a production run of clay that was improperly pugged (inadequate vacuum). The problem becomes evident weeks or months after pugging. In this case the clay body contained 2% talc, our production must make doubly sure to monitor vacuum pressure at all times (or laminations will result). These are not a problem if clay is wedged well before use. If not the laminations "build in" failure points that initiate drying and firing cracks later. Even if pieces survive the drying and firing processes, weaknesses can persist making them more prone to failure-on-impact or stress. This being said, does that mean you do not need to wedge plastic clay bodies if they are not laminated? No. All clays laminate to some extent when pugged.

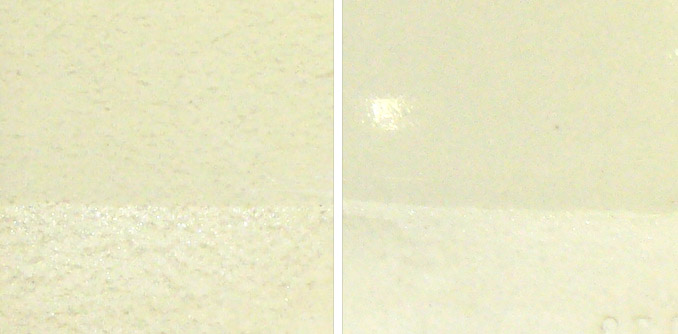

The de-airing process improves the smoothness of the fired surface

This picture has its own page with more detail, click here to see it.

These two close-ups of a fired cone 6 porcelain showing a big difference in surface smoothness. The deaired material on the right has a much smoother fired surface even though the non-deaired material on the left has been wedged much more. The transparent glaze does not hide the roughness.

A low-fire talc body lacks plasticity when slip-mixed, but not when pugged

This picture has its own page with more detail, click here to see it.

This clay was slurried in a mixer and then poured onto a plaster table for dewatering. During throwing it is splitting when stretched and peeling when cutting the base. Yet when this same clay is water-mixed and pugged in a vacuum de-airing pugmill it performs well. One might think that the slurry mixer would wet all the particle surfaces better than a pugmill - that is our typical experience. However, it appears the energy that a pugmill can inject into the mix is needed to develop the plasticity when there is a high talc percentage in the recipe.

Laminations in unwedged clay

This picture has its own page with more detail, click here to see it.

The brick-halves on the left cracked in two during drying, the crack opened at the center. I dried six of them and all cracked in the same way. The one-inch-slices were cut laterally from an extruded slug of clay and sun-dried. The radial pattern of the laminations are clearly visible on the break. These laminations are "a weakness" formed-into this extruded and unwedged clay, they would, of course, extend to fired integrity, weakening the piece. The halves on the right are from a brick that I made by first wedging (kneading) the clay, then forming and cutting it to size. It was likewise sun-dried. But did not crack. I broke it (with difficulty), notice the break followed the stresses of the breaking process, not internal lines of weakness.

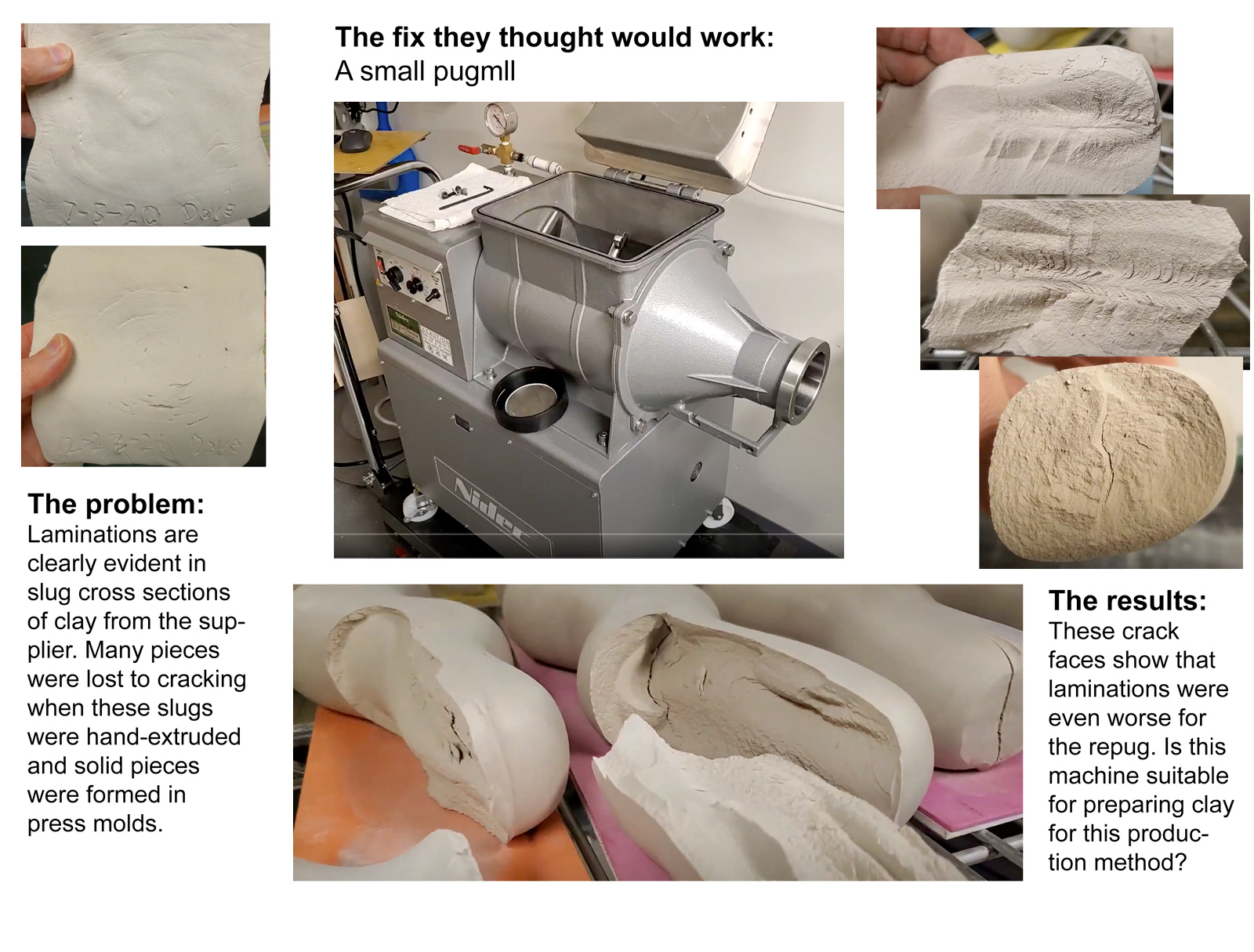

Laminations: Will a studio pugmill solve the problem?

This picture has its own page with more detail, click here to see it.

This company was plagued with drying cracks in their solid porcelain pieces. After some time they discovered that the deaired plastic material received from their suppliers had laminations (revealed in a cross section cut of the slug). Since they were not wedging, but simply inserting the clay into their hand extruders and presses, these laminations produced built-in weaknesses - the stresses of drying later exploited these. The obvious fix seemed to be to buy a mixer/pugmill to remix the clay. But that did not work. Why? Commercial pugmills commonly have multiple shafts, hundreds of blades, large powerful motors, separate mixing and vacuum chambers, shredders, high-compression heads, etc. Many small studio pugmills have none of these features. They are still great for recycling and mixing clay that will later be wedged. But for the machine-forming purposes of this company, this pugmill actually made the laminations worse! Would a deairing pugmill have solved the problem? There is still room for caution will studio equipment in production settings.

This simple device continuously gauges clay stiffness

This picture has its own page with more detail, click here to see it.

Here is how the pugmill operators at Plainsman Clays gauge the stiffness of the clay coming out of the pugmill. The machined nylon roller is on a slant and weighted. The softer the clay the more lines show. When they are like this (5th line steady) the operator knows the water content is around 22% for this clay, Polar Ice. For each type of clays it is different. Stiffness at pugging must also compensate when the clay tends to stiffen or soften over time. Over the years they have tried many devices to measure stiffness, but this has proven the most reliable.

A plaster table: Better than a pugmill, essential for testing

This picture has its own page with more detail, click here to see it.

This is an example of an angle iron utility table being made into a plaster table. The cardboard sides extend upward to make the slab thicker and create a buffer gap to prevent the expanding and setting plaster from pressing outward on the frame. 150 lbs plaster (92 lbs water) was poured into the plastic-lined space (the bottom cardboard sections were supported from below). In a dry enough climate, this table could make enough clay to support slurry-to-plastic production for a potter (a thicker slab and a fan would enable even more capacity). The slurry-up process is better than a pugmill for small operations. It's much cheaper and is an easier way to utilize scrap material and weigh out custom recipes. The clay quality and de-airing is better (without hard chunks and contamination common to pugmilling). The procedure generates much less dust and the tank is easily cleaned. Slurries are easily sieved, especially if you have a sieve shaker.

Links

| URLs |

https://starkeymachinery.com

Starkey Machinery Inc. They design, build and provide service for extrusion and process equipment for the ceramic industry including: Electrical porcelain, ceramic dinnerware & fine china, brick & tile, food processing equipment, glass & china and dinnerware. |

| URLs |

https://www.tilemachinery.com

Xiangtan Weida Electrical and Machinery Co., Ltd They make feeders, crushers and grinders, Raymond mills, ball mills and filter presses, mixers, pug mills, cutting machines, forming presses, setting machines, kilns and dryers. Also production lines for cordierite catalysts, clay roofing, terra cotta facades, tile and ceramic rollers. |

| Typecodes |

Clay mixers and pugmills

|

| By Tony Hansen Follow me on        |  |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy