| Monthly Tech-Tip | No tracking! No ads! |

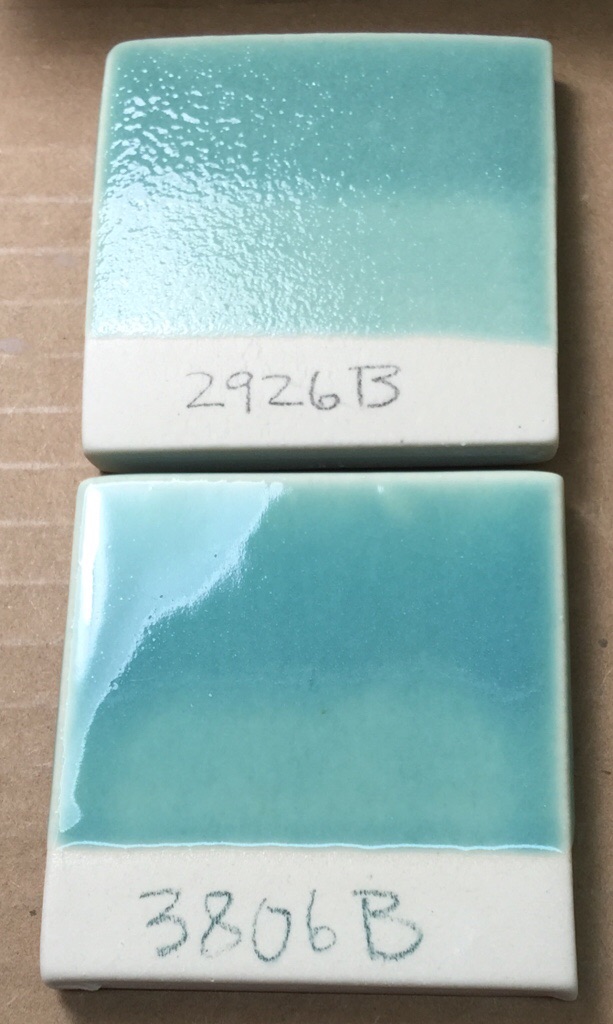

2% Copper carbonate in two different cone 6 copper-blues

The top base glaze has just enough melt fluidity to produce a brilliant transparent (without colorant additions). However it does not have enough fluidity to pass the bubbles and heal over from the decomposition of this added copper carbonate! Why is lower glaze passing the bubbles? How can it melt better yet have 65% less boron? How can it not be crazing when the COE calculates to 7.7 (vs. 6.4)? First, it has 40% less Al2O3 and SiO2 (which normally stiffen the melt). Second, it has higher flux content that is more diversified (it adds two new ones: SrO, ZnO). That zinc is a key to why it is melting so well and why it starts melting later (enabling unimpeded gas escape until then). It also benefits from the mixed-oxide-effect, the diversity itself improves the melt. And the crazing? The ZnO obviously pushes the COE down disproportionately to its percentage.

Videos

Links

| Materials |

Copper Carbonate Basic

This form of copper carbonate is the article of commerce, a mixture of theoretical copper carbonate and copper hydroxide. |

| Materials |

Zinc Oxide

A pure source of ZnO for ceramic glazes, it is 100% pure with no LOI. |

| Materials |

Copper Carbonate

A source of CuO copper oxide used in ceramic glazes to produce a variety of colors (used only or with other colorants). |

| Glossary |

Flux

Fluxes are the reason we can fire clay bodies and glazes in common kilns, they make glazes melt and bodies vitrify at lower temperatures. |

| Oxides | ZnO - Zinc Oxide |

| Recipes |

G3806C - Cone 6 Clear Fluid-Melt transparent glaze

A base fluid-melt glaze recipe developed by Tony Hansen. With colorant additions it forms reactive melts that variegate and run. It is more resistant to crazing than others. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy