| Monthly Tech-Tip | No tracking! No ads! |

Switching copper carbonate for copper oxide in a fluid glaze

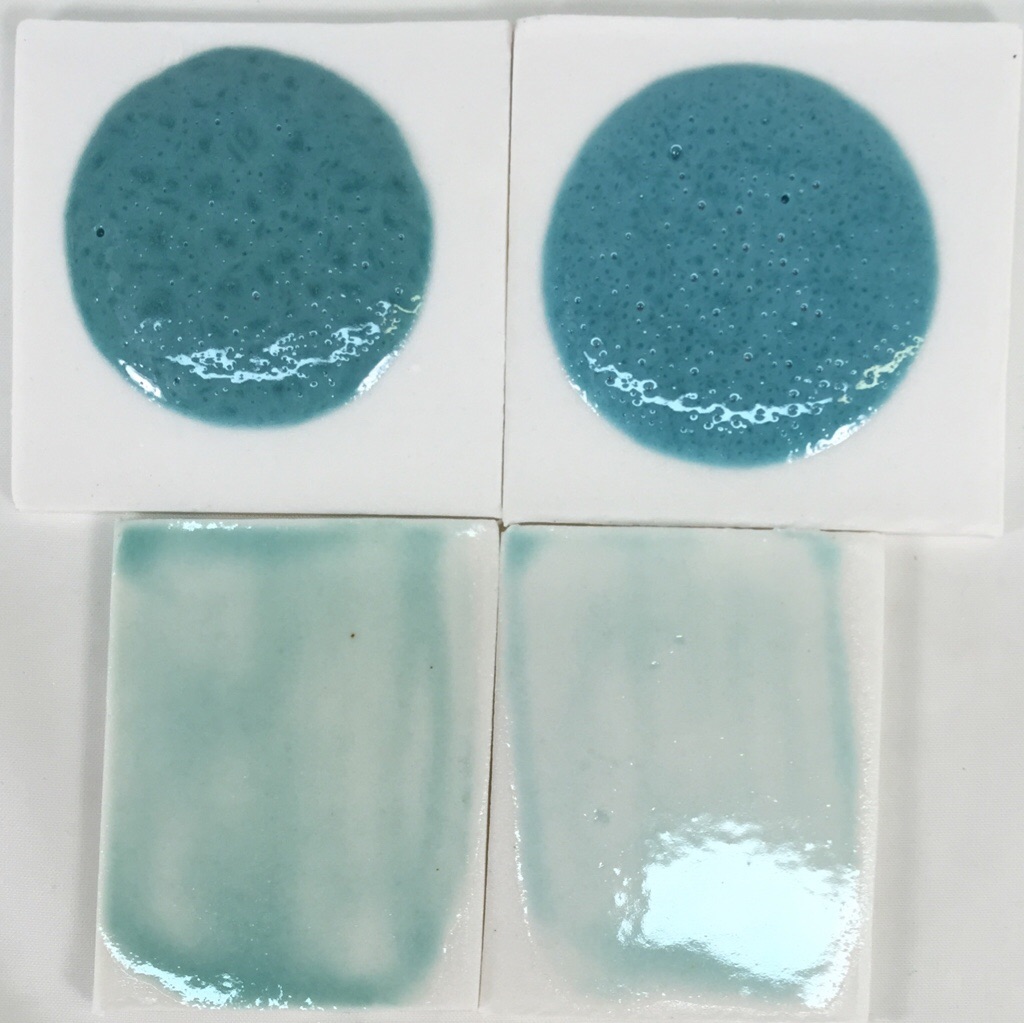

The top samples are 10 gram GBMF test balls melted down onto porcelain tiles at cone 6 (this is a high melt fluidity glaze). These balls demonstrate melt mobility and susceptibility to bubbling but also color (notice how washed out the color is for thin layers on the bottom two tiles). Both have the same chemistry but recipe 2 has been altered to improve slurry properties.

Left: Original recipe with high feldspar, low clay (poor suspending) using 1.75% copper carbonate.

Right: New recipe with low feldspar, higher clay (good suspending) using 1% copper oxide.

The copper oxide recipe is not bubbling any less even though copper oxide does not gas. The bubbles must be coming from the kaolin.

Videos

Links

| Materials |

Copper Oxide Black

The purest source of CuO copper oxide pigment used in ceramic glazes. |

| Materials |

Copper Carbonate Basic

This form of copper carbonate is the article of commerce, a mixture of theoretical copper carbonate and copper hydroxide. |

| Materials |

Copper Carbonate

A source of CuO copper oxide used in ceramic glazes to produce a variety of colors (used only or with other colorants). |

| Glossary |

Fluid Melt Glazes

Fluid melt glazes and over-melting, over fired, to the point that they run down off ware. This feature enables the development of super-floss and cyrstallization. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy