| Monthly Tech-Tip | No tracking! No ads! |

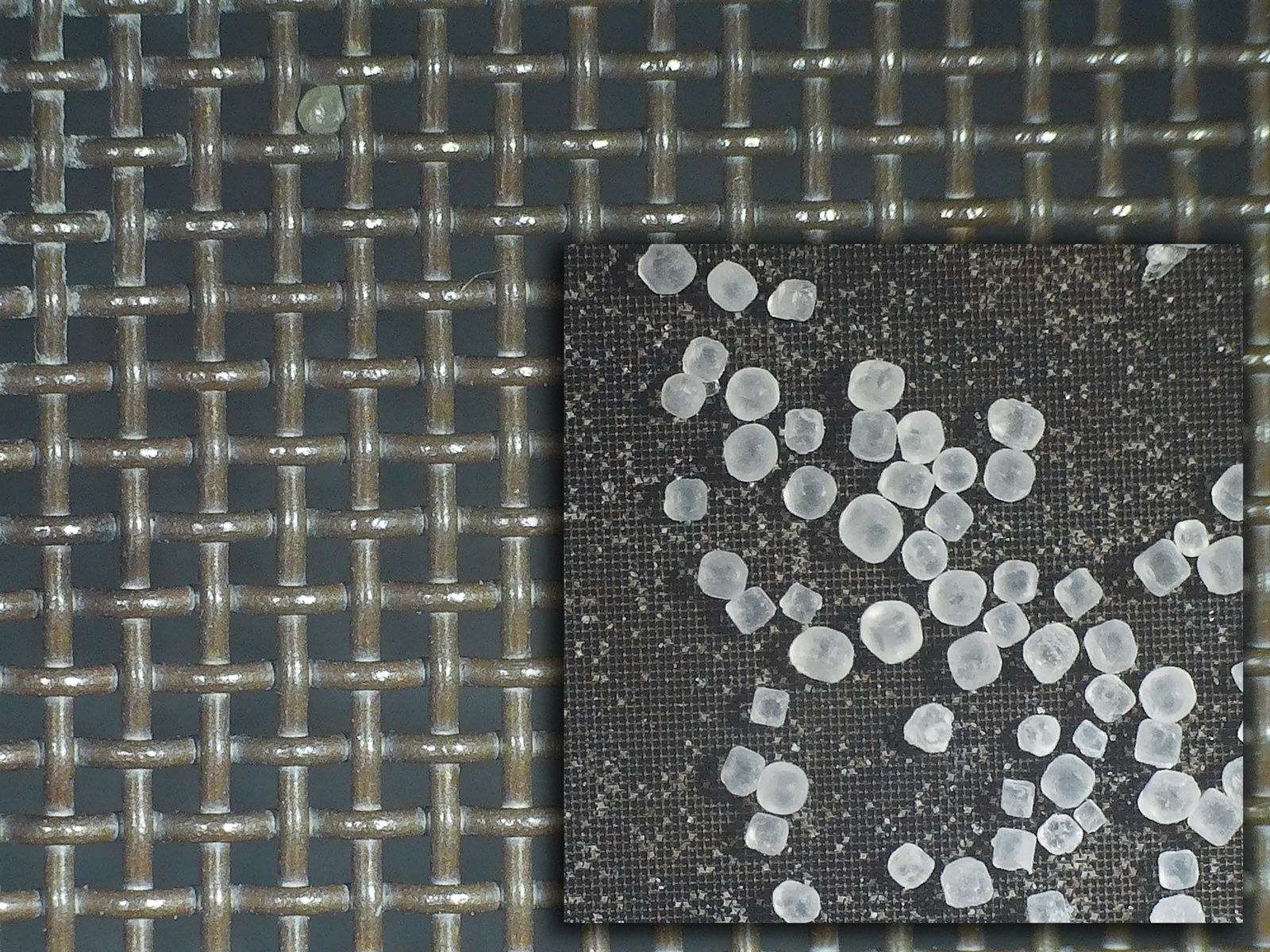

325 mesh

A 325 screen has 325 wires-per-inch (the finer of the two screen closeups shown here). Those are grains of salt on it (45 micron openings, a typical human hair is 50-100 microns thick). A 40 mesh screen is much coarser, it has 425 micron openings (that is a particle of quartz trapped in an opening). A minus 45 mesh powder will be too fluffy to drop through a 325 screen. But particles smaller than 45 microns in a slurry will pass. To get a slurry through a screen this fine one needs to take special measures. It needs to have a high water content so it is fluid. Using a soft brush definitely helps. And a source of vibration. And it is necessary to clean the screen often to remove trapped oversize material. 325 mesh screen fabric is fragile and a sieve like this needs to be treated with care. Laboratory quality sieves cost hundreds of dollars (but can often be found used on ebay).

Videos

Links

| Glossary |

Sieve

Sieves are important in ceramics for removing particulates and agglomerates from glaze, engobe and body slurries. |

| Glossary |

325 mesh

325 mesh (a sieve with 325 wires/inch) is the finest particle size that most ceramic minerals can be practically processed to (premium grades). |

| Glossary |

200 mesh

200 mesh (a sieve with 200 wires/inch) is the particle size that most minerals used in the ceramic industry are processed to. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy