| Monthly Tech-Tip | No tracking! No ads! |

Are you using your expensive kiln like a pop-up toaster?

Put the pots in, select a cone, press start. It is time to rethink that approach! The Bartlett Genesis kiln controller is standard equipment on hobby and production electric kilns now. It is not meant to be run like a toaster! Good glazes are about much more than recipes, they are about firing schedules. None of the built-in "toaster schedules" have hold times on any segments, drop-and-hold sequences or controlled cools. Or even fire-to-cone accuracy. Yet such are a must for defect-free glazes, enhancing the effects of reactive glazes that must develop crystallization or variegation or firing accurately. It is easy to program: Tap the blue edit button to edit a program, tap a column of any segment to edit its value. Tap a segment number to delete or duplicate it. Search "bartlett genesis controller" on YouTube for videos on creating and editing a schedule.

Related Pictures

At what point is a self-supporting cone bent to the correct degree?

This picture has its own page with more detail, click here to see it.

Orton says “90 angular degrees is considered the endpoint of cone bending”. First, let's assume the normal: Examination of cones on kiln-opening to verify controller operation. Consider the cone on the left: The tip is touching. But it is also beginning to buckle, which means it was touching for a while before the firing ended. Who knows how long! The second one is not touching but has still fallen a little too far. Why do we say that? The third one, positioned on the Orton guide, has reached the recommended 90 degrees. This demonstrates a good reason why self-supporting cones are much better than standard ones: They are not touching when considered done. And standard cones, when set in a 3/4" plaque, have a less consistent bending behaviour.

When the cone does this I need to adjust the program

This picture has its own page with more detail, click here to see it.

This is a cone 04. It is bent too much, the kiln has over-fired a little (cone 03 was also bent somewhat). The built-in firing schedule goes to 1945, that would be much more over-fired than this was (and the built-in ones do not soak, drop-and-soak or slow cool). It only takes a minute to edit the program I made, all I have done is drop the step-three temperature to 1930 (it was 1935). I adjust my schedule fire-up-to temperature as needed, I cannot imagine not doing this.

Manually programming a Bartlett V6-CF hobby kiln controller

This picture has its own page with more detail, click here to see it.

I document programs in my account at insight-live.com, then print them out and enter them into the controller. This controller can hold six, it calls them Users. The one I last edited is the one that runs when I press "Start". When I press the "Enter Program" button it asks which User: I key in "2" (for my cone 6 lab tests). It asks how many segments: I press Enter to accept the 3 (remember, I am editing the program). After that it asks questions about each step (rows 2, 3, 4): the Ramp "rA" (degrees F/hr), the Temperature to go to (°F) to and the Hold time in minutes (HLdx). In this program I am heating at 300F/hr to 240F and holding 60 minutes, then 400/hr to 2095 and holding zero minutes, then at 108/hr to 2195 and holding 10 minutes. The last step is to set a temperature where an alarm should start sounding (I set 9999 so it will never sound). When complete it reads "Idle". Then I press the "Start" button to begin. If I want to change it I press the "Stop" button. Those ten other buttons? Don't use them, automatic firing is not accurate. One more thing: If it is not responding to "Enter Program" press the Stop button first.

Bloating with multiple bodies at cone 6: Why is this happening?

This picture has its own page with more detail, click here to see it.

The problem occurred with standard Plainsman M340, M390, M350, M370 and P300. The stonewares have porosities of 2-3%, the M370 1% and the P300 0.5%. Thus, all of these have comfortable margins for overfiring. The G2926B glaze, used on all of them, does seal the surface pretty early so it can contribute to over-fired ware bloating sooner than typical. But the problem here is

likely the cone-fire modes on hobby kiln controllers. For this kiln, the cone 6 program goes to 2236F. That's cone 7. Adding the error of the thermocouple and the misinformation from poorly set cones the temperature overshoot could be more. That means this ware is likely just over-fired. Manually programming your kilns in consort with calibration using self-supporting cones, that is the way to get control. Add to that the benefit from firing schedules like the drop-and-soak PLC6DS and slow-cool C6DHSC.

Cones bending badly, cones bending goodly

This picture has its own page with more detail, click here to see it.

Ware is not turning out as expected and a potter needs to verify the temperature in the kiln. The standard cones on the upper right are misleading. The cone 7 is telling one story but the cone 6 and 5 another. On the lower right is a better way: Self supporting cones. They are always at the right angle and this set of three is bending as expected. To be a full cone 6 the middle one needs to bend just a little more until the tip is even with the top of the base (maybe 2 or 3 degrees). On the top set, the cone 6 is clearly totally flattened and the 5 is a pool of glass, this firing went way beyond cone 6.

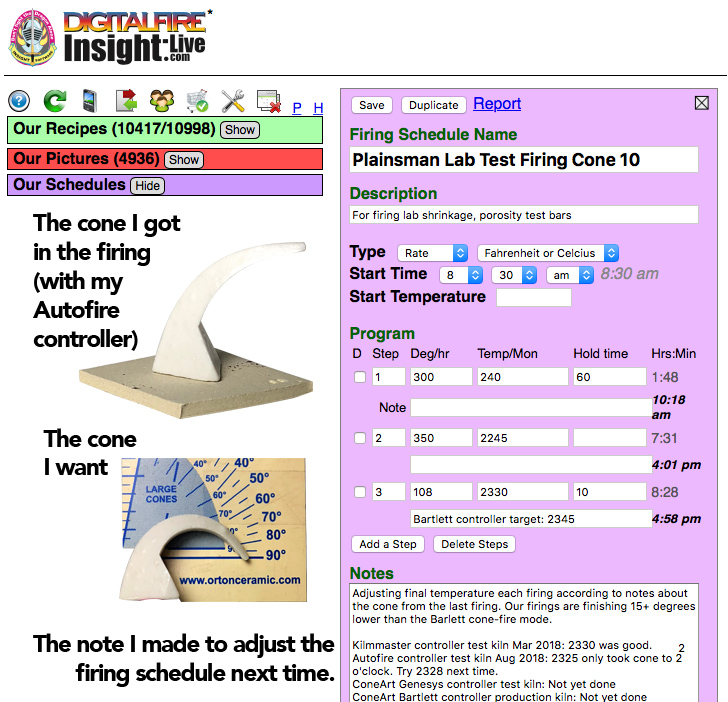

Program your firings manually, calibrate the final temperature using cones

This picture has its own page with more detail, click here to see it.

Here is an example of our lab firing schedule for cone 10 oxidation (which the cone-fire mode does not do correctly). To actually go to cone 10 we need to manually create a program that fires higher than the built in cone-fire one. Determining how high to go is a matter repeated firings verified using a self-supporting cone (regular cones are not accurate). In our lab we keep notes in the schedule record in our account at insight-live.com. And we have a chart on the wall showing the latest temperature for each of the cones we fire to. What about cone 6? Controllers fire it to 2235, we put down a cone at 2200!

Videos

Links

| URLs |

https://www.youtube.com/watch?v=gbA_Jv6J_BY

Bartlett Genesis Kiln Controller Programming |

| Articles |

Working with children

Go in with both eyes open if you are planning to work with clay with a group of children! A lot can go wrong but it can be unforgettable for them when it goes right. |

| Glossary |

Firing Schedule

Designing a good kiln firing schedule for your ware is a very important, and often overlooked factor for obtained successful firings. |

| Glossary |

Kiln Controller

In ceramic kilns the firing schedule is typically managed automatically by an electronic controller. But that may not mean that ware gets automatically fired to the correct temperature and atmosphere. |

Got a Question?

Buy me a coffee and we can talk

https://digitalfire.com, All Rights Reserved

Privacy Policy